Optimizing Steel Wire Packaging: A Deep Dive into Automated Coil Wrapping Solutions

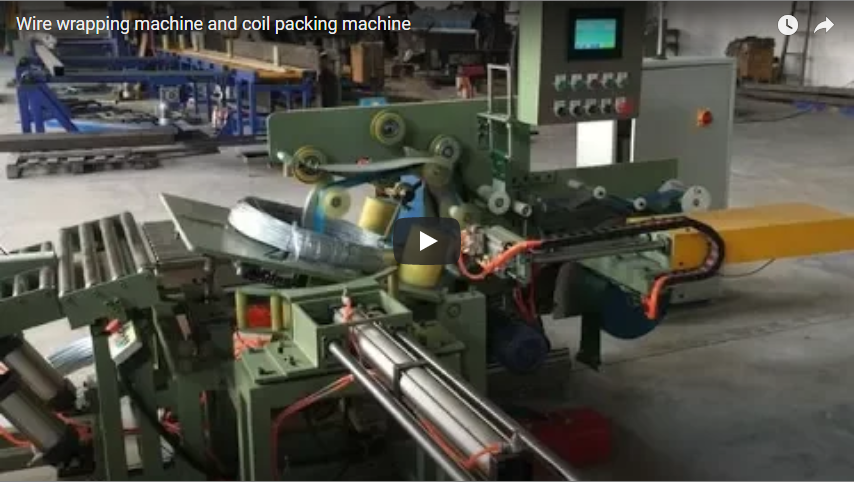

In today's demanding steel processing and distribution landscape, ensuring the integrity and safe handling of steel wire coils is paramount. Manual packaging methods often fall short, leading to inefficiencies, potential product damage, and increased labor costs. Automated steel wire coil wrapping machines, as demonstrated in the video above, represent a significant technological advancement, offering robust protection and streamlined operations. This article explores the technology, benefits, and applications of these essential systems, drawing insights from industry best practices and technical specifications.

The video highlights a popular configuration utilizing PP woven sheet and stretch film for comprehensive coil protection. This dual-material approach is frequently cited in packaging studies for its effectiveness against moisture, dust, and physical abrasion during transit and storage. Such automated systems are engineered for efficiency, typically achieving cycle times of 20-35 seconds per coil, a marked improvement over manual methods, contributing directly to increased throughput and reduced operational bottlenecks.

The Critical Role of Protective Packaging in the Steel Industry

Steel wire is susceptible to environmental factors like humidity, leading to corrosion, and physical damage during handling and transportation. Inadequate packaging can result in significant financial losses due to product rejection or rework. Research published in materials science journals consistently emphasizes the need for barrier packaging to preserve the metallurgical properties and surface finish of steel products. Automated wrapping machines address this by providing consistent, tightly applied layers of protective materials.

Modern systems often incorporate features discussed in packaging technology patents, such as advanced film pre-stretch mechanisms (sometimes achieving over 300% stretch), which optimize material usage and enhance load containment force, ensuring coil stability. Utilizing larger rolls of wrapping material, such as paper or woven sheets loaded onto dedicated stations, minimizes downtime associated with material reloading, further boosting Overall Equipment Effectiveness (OEE).

Understanding the Technology: How Steel Wire Coil Wrappers Work

A Steel Wire Coil Wrapping Machine is specifically engineered to apply protective films or sheets around the circumference and potentially the bore of steel wire coils. Key components and operational principles include:

- Robust Frame and Coil Support: Designed to handle significant weights, often up to several metric tons, with stable support structures (e.g., rollers, V-blocks) to securely hold the coil during wrapping.

- Wrapping Mechanism: Typically involves either a rotating turntable that spins the coil while film is dispensed from a stationary mast, or a rotary ring/arm that orbits around a stationary coil. The vertical wrapping configuration, as seen in some systems, is particularly adept at securing coils loaded with their axis vertical.

- Film Delivery System: Incorporates mounts for various wrapping materials (stretch film, PP woven, VCI paper/film). Crucially, it features tension control systems – ranging from simple mechanical brakes to sophisticated electronically controlled pre-stretch units – ensuring consistent film application without damaging the coil or wasting material. According to Packaging Digest analyses, precise tension control is key to load integrity.

- Automation and Control: Modern machines are typically managed via Programmable Logic Controllers (PLCs) with Human-Machine Interfaces (HMIs). This allows for parameter adjustments (wrap counts, tension levels, overlap percentages), recipe storage for different coil sizes, diagnostic feedback, and potential integration with plant-level control systems (MES/ERP).

- Cutting and Clamping: Automated systems feature mechanisms to cleanly cut the wrapping material at the end of the cycle and clamp it securely, preparing the machine for the next coil.

This vertical stretch film wrapping machine efficiently wraps steel wire coils for safer and more economical handling, storage and transportation. Industry reports indicate such machines can typically handle steel wire coil diameters up to 60 inches and weights approaching 2 metric tons or more, depending on the specific model configuration.

The coil wrapping machine vertically wraps stretch film (and potentially other materials) around steel wire coils. It consists of a sturdy vertical frame with coil supports, stretch film roll mounts, and integrated tensioning/cutting systems. Steel wire coils are loaded onto the supports (often via crane, forklift, or conveyor) and positioned for wrapping. The wrapping cycle commences, applying the film with controlled tension and overlap.

Key Specifications and Performance Metrics

While the parameters below offer a general guideline, specific machine capabilities can vary. Always consult the manufacturer for exact specifications matching your application requirements.

- Machine Type: Fully Automatic Wire Coil Wrapping System

- Coil Handling Capacity:

- Diameter Range: Typically 600mm to 1600mm (customizable)

- Width Range: Typically 300mm to 1200mm (customizable)

- Max Weight: Systems often rated for 2000kg or higher

- Wrapping Materials: Versatile compatibility including LLDPE Stretch Film, PP Woven Sheet, VCI Paper/Film, HDPE Film, Crepe Paper.

- Performance:

- Wrapping Speed: Variable, often up to 35 wraps/minute or cycle times of 20-60 seconds per coil, depending on size and wrap pattern complexity.

- Adjustable Film Tension Control: Essential for optimal load containment and material economy.

- Film Overlap Control: Adjustable via PLC/HMI for desired level of protection.

- Film Roll Specifications:

- Max Outer Diameter: e.g., up to 250mm

- Inner Core Diameter: Standard 76mm (3 inches)

- Film Width Capability: e.g., up to 500mm

- Control System: PLC-controlled with user-friendly HMI touchscreen.

- Utility Requirements:

- Power: Typically 3-phase power (e.g., 480V/60Hz or 380V/50Hz), specific connection required.

- Compressed Air: Often required for clamping/cutting mechanisms (e.g., 6 bar).

- Physical Dimensions: Variable based on model (Example: L: 3400mm; W: 1500mm; H: 2200mm)

- Approximate Weight: e.g., 750kg (highly variable)

- Safety Features: Emergency stop circuits, safety interlocks on guards/doors, light curtains (optional), conforming to relevant safety standards (e.g., CE, OSHA guidelines).

- Power Consumption: Reflective of motor sizes and cycle rates (Example: 2.5 kW - 5 kW).

Note: The parameters listed above are indicative and may not perfectly match the equipment shown in the video. For precise specifications tailored to your needs, direct consultation is recommended.

Strategic Applications Across the Supply Chain

The adoption of automated steel wire coil wrapping machines delivers tangible benefits across various industrial sectors:

-

Logistics and Shipping: Enhancing Transport Efficiency & Safety

Securely unitized coils are fundamental for safe and efficient logistics. Automated wrapping minimizes the risk of coil unwinding or shifting during transit (road, rail, or sea), significantly reducing potential product damage and transport-related accidents. The Fabricator magazine frequently highlights how improved load containment translates to safer handling, optimized space utilization in containers and trucks, and reduced damage claims, directly impacting the bottom line. -

Metallurgical Industry: Preserving Product Integrity and Value

In primary steel production and downstream processing, maintaining the quality of steel wire is non-negotiable. Automated wrapping provides a consistent, high-quality barrier against atmospheric corrosion, dust accumulation, and handling damage. The ability to incorporate Volatile Corrosion Inhibitor (VCI) films directly into the wrapping process offers enhanced, long-term protection, crucial for export shipments or extended storage periods, as documented in corrosion engineering studies. -

Manufacturing Plants: Streamlining Workflows and Reducing Costs

For manufacturers using steel wire as feedstock (e.g., automotive components, construction materials, appliance parts), receiving securely wrapped, undamaged coils is vital for uninterrupted production. Integrating automated wrappers at the end of production or processing lines streamlines material flow, reduces manual handling requirements (improving ergonomics and lowering labor costs), and ensures coils are ready for immediate inventory stocking or JIT shipment. The consistency achieved surpasses manual efforts, enhancing overall product quality perception.

Expanding Packaging Capabilities

For operations requiring higher throughput or more complex packaging solutions, further automation options exist. Exploring advanced systems can reveal opportunities to further reduce labor dependency and enhance packaging consistency.

More solution for the speed up wire coil packaging in reducing the labor cost just here: