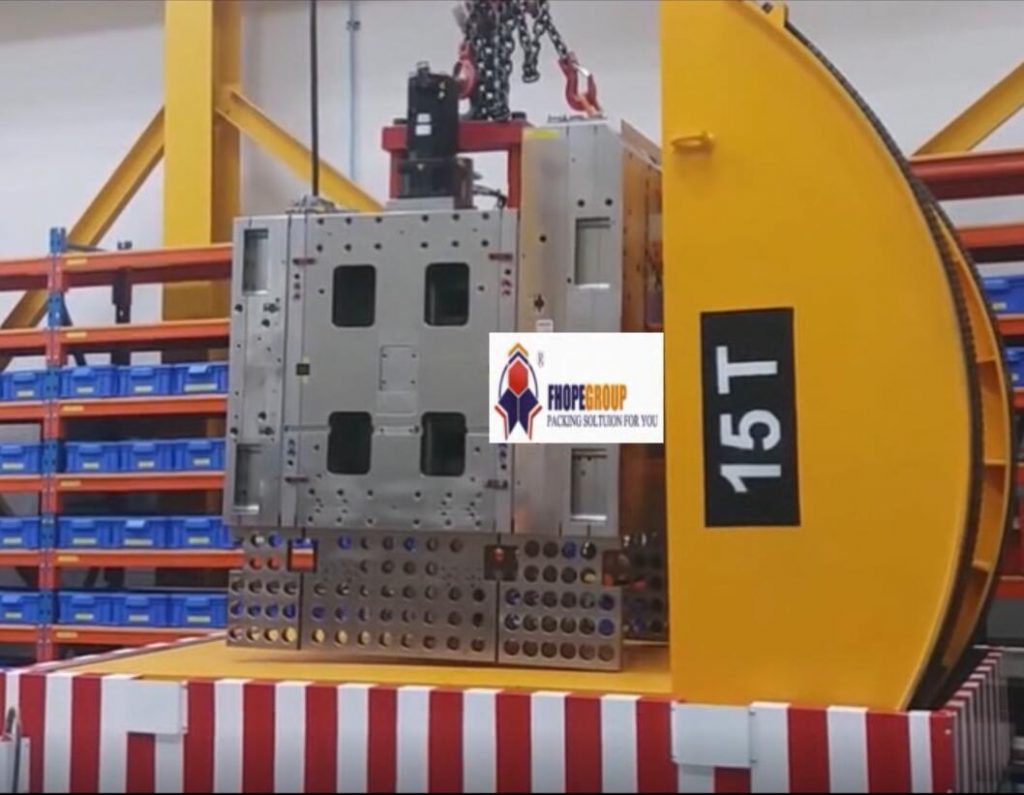

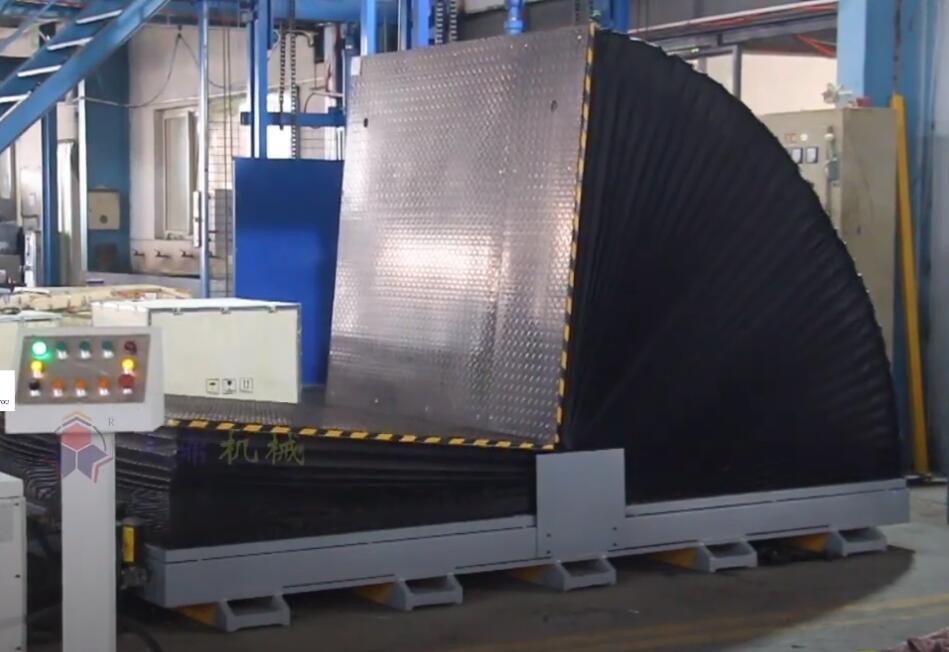

This is the video fo the Steel sheet pallet chagning machine.

It is for changing the pallet by 180 degree turning that is for changing the pallet upside down.

A Steel Sheet Pallet Inverter is a specialized piece of equipment used predominantly in the material handling and manufacturing sectors. This machine is strategically engineered to rotate steel sheets along with their pallets, flipping them by 180 degrees. This function is vital for the quick reorientation of steel sheets, allowing for the easy replacement of pallets or the removal of damaged sheets from the bottom without manual labor. Steel sheet pallet inverters are typically robust, featuring hydraulic or pneumatic flipping mechanisms and are equipped with adjustable clamping systems to secure various sizes and weights of metal sheets, ensuring safety and efficiency.

The parameters below do not 100% match the equipment in the video. For exact specifications, please contact us.

- Machine Type: Hydraulic Pallet Inverter

- Application: Steel Sheets, Heavy Flat Materials

- Material Handling Capacity: Up to 5000 kg

- Rotation Angle: 180 degrees

- Clamping Mechanism: Adjustable pressure settings

- Power Requirements: 480V, 60Hz, three-phase

- Machine Dimensions: Length: 3000mm; Width: 2000mm; Height: 2500mm

- Control System: Manual or automated controls

- Frame Material: Heavy-duty steel

- Safety Features: Emergency stop, safety cages

- Cycle Time: Approx. 30 seconds per cycle

- Operational Environment: Suitable for both indoor and outdoor use

- Maintenance Check Frequency: Bi-annually or after 10,000 cycles

Applications of the Steel Sheet Pallet Inverter:

- Metal Fabrication Facilities: Efficiency in Material Handling

In metal fabrication plants, where the handling of heavy steel sheets is frequent, the Steel Sheet Pallet Inverter plays a crucial role in improving operational efficiency. By allowing rapid flipping of steel sheets, the machine minimizes the need for manual labor, reducing downtime and increasing productivity. This capability is particularly beneficial when dealing with large volumes or heavy sheets that can pose safety risks if handled manually. - Automotive Manufacturing: Enhancing Safety and Reducing Damage

Within the automotive industry, the precision and condition of steel sheets are paramount. The pallet inverter allows workers to quickly remove or replace damaged sheets on a pallet without the need to manually restack the entire load. This not only ensures the quality of the materials used in the production of vehicles but also enhances safety by reducing the risk of accidents associated with manual handling of heavy materials. - Warehouse Operations: Improved Storage and Accessibility

In warehousing environments where space is often a premium, the ability to quickly rotate and organize steel sheets using a pallet inverter helps maximize use of storage space and improves accessibility. This equipment allows warehouse operators to stack and store materials more effectively, facilitating easier access and better inventory management, which in turn optimizes space and increases operational efficiency in storing and retrieving heavy steel sheets.