The inline steel coil packing line is designed with cutting-edge technology, featuring an eye stretch wrapper, circumferential strapping machines, and radial strapping machines. This sophisticated system ensures that steel coils are securely and efficiently packaged, enhancing both safety and durability during transportation and storage .

The packing line operates with a high level of automation, categorized into Level one, Level two, and Level three, which streamlines operations and reduces the need for manual intervention. This automation is further enhanced by digital sharing capabilities with a Manufacturing Execution System (MES), allowing for seamless integration and real-time data exchange across the production process. This connectivity not only improves operational efficiency but also facilitates better decision-making through comprehensive data analysis .

Additionally, the system is designed to connect directly with a cold rolled coil production line and an automatic steel coil storage system, creating a fully integrated production and packaging solution. This integration ensures a smooth transition from production to packaging and storage, reducing downtime and optimizing workflow .

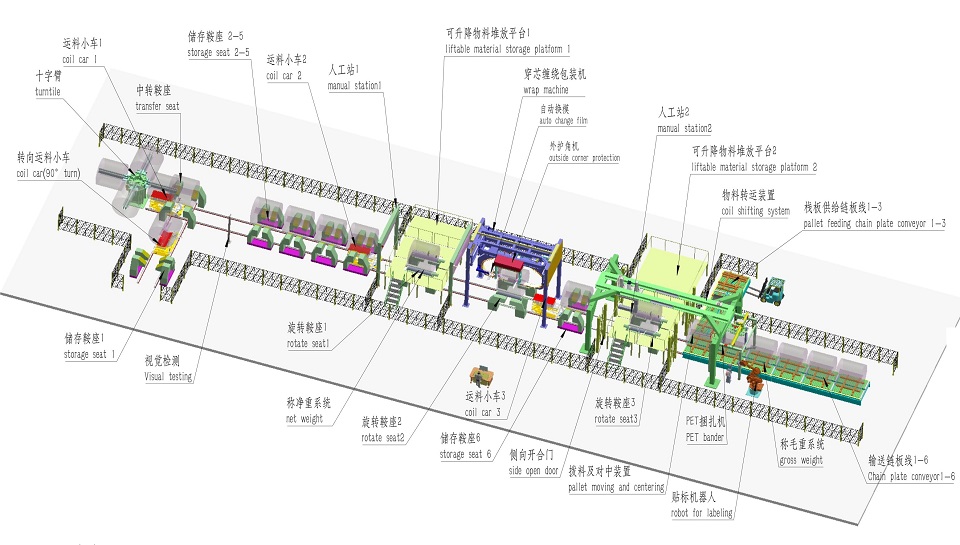

The system's design is tailored to the specific factory layout and packaging requirements, ensuring that it meets the unique needs of each facility. This customization is crucial for maximizing space utilization and ensuring that the system operates efficiently within the constraints of the existing infrastructure. A detailed drawing of a production line demonstrates the functions of each part, providing a clear overview of the system's capabilities and layout .

In summary, the inline steel coil packing line represents a significant advancement in packaging technology, offering high levels of automation, integration with production and storage systems, and customization to meet specific factory needs. This makes it an ideal solution for modern steel production facilities seeking to enhance efficiency and productivity.