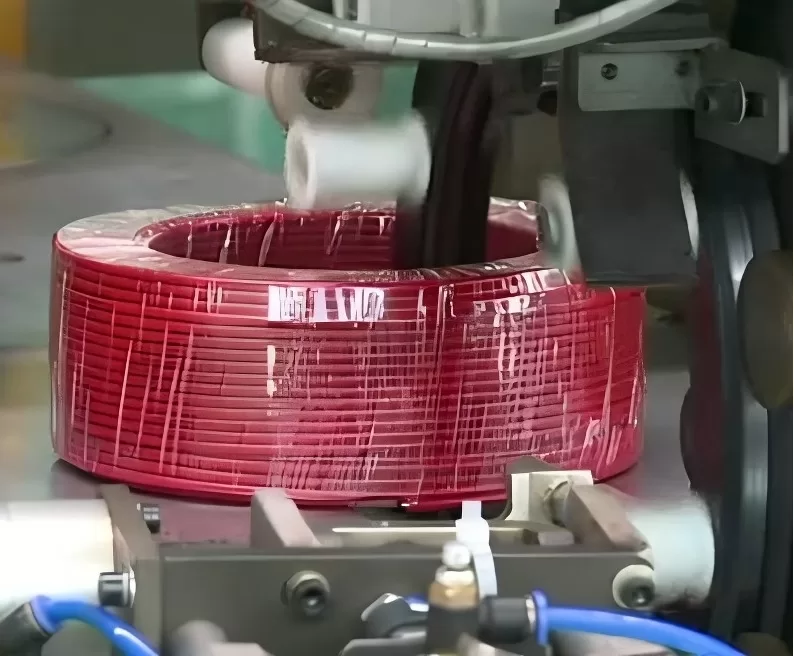

Mastering Small Cable Coil Packaging: A Closer Look at Fhopepack's Automatic Wrapper (ID 120mm+)

In the dynamic world of wire and cable manufacturing, efficient and secure packaging is paramount. While larger coils have established handling solutions, smaller cable coils often present unique challenges, demanding precision, speed, and protection without excessive labor. Addressing this specific need head-on, Fhopepack delivers a specialized solution: the Automatic Cable Coil Wrapping Machine, expertly engineered for coils starting with an inner diameter (ID) as small as 120mm.

This isn't just about wrapping; it's about optimizing your entire packaging workflow for those demanding smaller dimensions. Let's delve deeper into how this machine elevates the process.

1. Deep Dive: Technical Specifications & Capabilities

Understanding the core capabilities is crucial for evaluating if this machine fits your operational needs. Here’s a snapshot of its technical prowess:

- Minimum Coil ID: 120mm (Customizable options available for other specific sizes)

- Typical Coil OD Range: Dependent on ID and width, designed for small to medium coil sizes.

- Typical Coil Width Range: Accommodates various standard small cable coil widths.

- Control System: Advanced PLC (Programmable Logic Controller) for precise, repeatable operations and easy parameter adjustments.

- Automation Level: Fully automatic wrapping cycle, minimizing manual intervention.

- Wrapping Material: Primarily utilizes Stretch Film (LLDPE), offering excellent load containment and protection. Compatibility with other materials like VCI film can often be integrated upon request.

- Wrapping Speed: Optimized for efficiency, significantly reducing cycle time compared to manual or semi-automatic methods.

- Power Requirements: Standard industrial power compatibility (details provided upon configuration).

2. Operational Excellence: How It Works – A Seamless Flow

The beauty of this machine lies in its automated simplicity from an operator's perspective:

- Loading: The small cable coil is placed onto the designated loading area or integrated conveyor system.

- Positioning: The machine automatically positions the coil correctly for the wrapping cycle to begin.

- Wrapping Cycle Initiation: Triggered automatically or via a simple operator command.

- Film Application: The wrapping ring dispenses and applies the stretch film around the coil's outer circumference, passing through the eye (ID) seamlessly. The PLC controls the overlap and number of wraps according to pre-set parameters.

- Film Cutting & Clamping: Upon cycle completion, the film is automatically cut and secured (clamped/wiped), ensuring a clean finish without loose ends.

- Unloading: The securely wrapped coil is ready for removal or transfer to the next stage (e.g., palletizing).

This automated sequence ensures consistency, eliminates operator variability, and maximizes throughput.

3. Beyond the Basics: Key Features & Tangible Benefits

Migrating to an automated solution like Fhopepack’s offers substantial advantages:

- Enhanced Efficiency: Drastically reduces the time required to package each small coil, boosting overall production output.

- Labor Cost Reduction: Frees up personnel previously tied up in manual wrapping for more value-added tasks.

- Consistent Quality: Guarantees uniform wrap tension and coverage for every coil, enhancing package integrity and appearance.

- Improved Product Protection: Tightly wrapped coils are better protected against dust, moisture, shifting, and handling damage during transit and storage.

- Material Savings: Precise PLC control optimizes stretch film usage, minimizing waste compared to manual application.

- Operator Safety: Enclosed wrapping process and available safety features reduce risks associated with manual handling and cutting tools.

- Customization: Tailor wrapping parameters (overlap, layers, tension) easily via the PLC interface to suit different cable types or customer requirements.

4. Real-World Application: A User-Centric Perspective

From interacting with operations managers and packaging engineers who've integrated similar automated systems, the feedback often highlights the transformative impact on workflow. The ability to reliably and quickly process small, often fiddly, coils removes a significant bottleneck. Operators appreciate the ease of use provided by the PLC interface and the reduction in physically demanding repetitive motions. The consistency achieved translates directly to fewer complaints about transit damage and a more professional product presentation upon arrival. It shifts the focus from a manual chore to a streamlined, reliable process step.

5. Customization and Integration Flexibility

Fhopepack recognizes that 'one size fits all' rarely applies in manufacturing. Beyond the core 120mm ID capability, options often include:

- Adjustments for specific non-standard ID/OD/Width dimensions.

- Integration with existing infeed and outfeed conveyor systems for a fully inline process.

- Options for different wrapping materials or combined wrapping/labeling solutions.

- Enhanced safety features or specific environmental protection ratings (e.g., washdown environments).

Discussing your unique operational context with Fhopepack allows for tailoring the machine to perfectly match your production line's needs.

6. Choosing the Right Partner: The Fhopepack Advantage

Fhopepack brings considerable expertise specifically to the domain of coil wrapping and packaging machinery. Their focus on providing solutions for various coil sizes, including these challenging smaller dimensions, demonstrates a deep understanding of the industry's needs. Opting for their automatic cable coil wrapping machine means investing in:

- A robust, purpose-built machine designed for longevity.

- Technology focused on efficiency and precision (PLC control).

- Potential for customization and integration support.

- Access to their broader range of coil packaging solutions should your needs evolve.

For companies handling significant volumes of small cable or wire coils, this automated wrapping machine represents a smart investment towards improved efficiency, reduced costs, and enhanced product quality.

Looking for more information on coil packaging solutions?

Explore Fhopepack's range of machinery: https://www.fhopepack.com/Coil_packing_machine.html

Contact Fhopepack directly for inquiries: info@fhopepack.com