A Stretch Hood Bag Packing Machine for EPS Insulation Panels is specifically designed to package expanded polystyrene (EPS) insulation panels efficiently. These machines utilize a stretch hooding method, where a continuous film tube is stretched and then applied over the load, effectively creating a tight, secure, and sealed package. This method provides excellent protection against moisture and dust, making it quite suitable for the insulation panels which require stringent protection standards. The components include an automated film feed, cutting mechanism, and a stretching system capable of adapting to various panel dimensions. This machine is typically crafted with high-grade, heavy-duty materials to endure the demanding conditions of industrial environments.

The parameters below do not 100% match the equipment in the video. For exact dospecifications, please contact us.

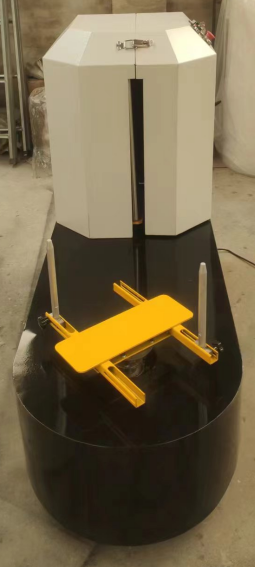

- Type: Stretch Hood Bag Packing Machine

- Application: EPS Insulation Panels

- Production Year: 2023

- Wrapping Capacity: Up to 60 panels per hour

- Panel Size Compatibility: Maximum 1200mm x 4000mm

- Film Type: Polyethylene, up to 200 microns thick

- Adjustable Film Stretch: Up to 25%

- Machine Control: Programmable Logic Controller (PLC) with touchscreen operation

- Power Requirement: 440V, 60Hz, three phase

- Machine Dimensions: Length: 5200mm; Width: 2400mm; Height: 2800mm

- Compliance: ISO 9001:2015, CE mark

- Wrapping Efficiency: Less than 2 minutes per pack

- Safety Mechanism: Guarding with automatic shutdown

- Warranty: 5 years for major components

Applications of the Stretch Hood Bag Packing Machine for EPS Insolation Panels:

- Building Material Suppliers: Enhanced Transport and Storage

For suppliers of building materials, this machine offers key advantages in the transport and storage of EPS insulation panels. By using a secure stretch hood, each panel stack is tightly sealed, thus preventing the ingress of moisture which can compromise the insulation performance. The tight packaging also makes handling and stacking easier and safer, reducing the risk of damage during transit and resultantly minimizes waste. - Home Renovation Retailers: Improved Product Presentation

Home renovation retailers can benefit greatly by ensuring their EPS panels are well-protected and presented attractively on the sales floor. The Stretch Hood Bag Packing Machine offers a clean and professional appearance of packaged goods while providing visible assurance of product integrity to consumers. This not only enhances customer trust but could also increase sales through better product presentation. - Construction Projects: On-site Material Management

On construction sites, managing materials effectively is crucial due to exposure to various environmental conditions and operational hazards. Using the Stretch Hood Bag Packing Machine for EPS insulation panels ensures that these materials remain protected from dust, debris, and water, thus maintaining their insulation properties. Additionally, neatly packaged materials improve site organization, reduce retrieval time, and prevent project delays associated with material damage and replacement.