This is a video for door shrinking machine.

Safety and Efficiency Combined: The Role of Automatic Door Packing Line

Safety and Efficiency Combined: The Role of Automatic Door Packing Lines

In today’s fast-paced manufacturing environment, efficiency and safety are more crucial than ever. For industries producing large-scale products like doors, the packaging process can make or break the smooth flow of operations. This is where the Automatic Door Packing Line comes in. By combining cutting-edge technology with streamlined processes, companies can dramatically improve productivity, safety, and product protection.

In this comprehensive guide, we’ll explore the importance of automatic door packing lines, how they work, their safety and efficiency benefits, and why they are essential for modern manufacturing operations. Whether you’re a manufacturer looking to enhance your production line or simply interested in the latest packaging technology, this article will provide an in-depth look at how automatic door packing lines can revolutionize your business.

1. Introduction to Automatic Door Packing Lines

An Automatic Door Packing Line is a highly specialized, automated system designed to wrap and package doors of various sizes and materials. The primary function of this system is to ensure that each door is securely wrapped and protected from potential damage during transport or storage.

These packing lines are equipped with advanced features that allow for precision wrapping, sealing, and shrinking, ensuring that the final product is well-protected against elements such as dust, moisture, and minor impacts. With the ability to process up to 120 doors per hour, these machines are a game-changer for industries looking to scale up their production while maintaining high-quality standards.

1.1 The Growing Need for Automation in Packaging

As industries grow and consumer demand increases, the need for automation in packaging has become more pronounced. Manual packaging is not only time-consuming but also prone to errors, which can lead to damaged products and increased costs. Automation solves many of these issues by providing a faster, more efficient, and reliable packaging process.

In sectors such as construction, manufacturing, and home improvement, where doors are produced in bulk, automatic packing lines are indispensable. These systems ensure that every door is packaged consistently, reducing the chances of human error and ensuring that the product is well-protected during transportation.

2. How an Automatic Door Packing Line Works

Understanding the working process of an automatic door packing line is key to appreciating its benefits. The process typically involves several stages, each designed to ensure that the door is securely packaged and protected.

2.1 Manual Door Placement

The process begins with manual door placement on the infeed conveyor. At this stage, an operator ensures that the door is properly aligned and oriented for the packaging process. While this is the only manual step in the entire process, it is crucial for ensuring that the door is positioned correctly before the automated sequence begins.

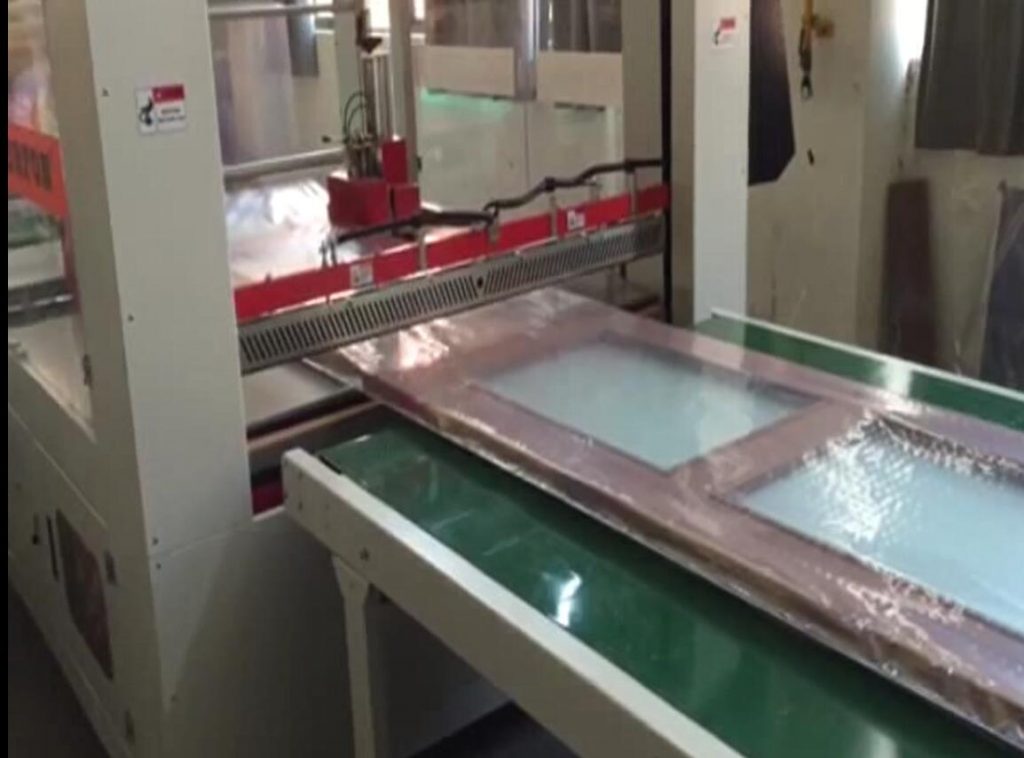

2.2 Film Covering and Sealing

Once the door is positioned on the conveyor, the system moves it into the film covering and sealing station. Here, the door is wrapped in a protective film, which is automatically sealed around its perimeter. Advanced tensioning mechanisms ensure wrinkle-free coverage, and the seams created during the sealing process are strong and uniform to prevent any tearing or loosening during transit.

2.3 Shrinking Tunnel

After the door is wrapped and sealed, it enters the shrinking tunnel. In this stage, controlled heat is applied to the film, causing it to shrink tightly around the door. The temperature is precisely regulated to ensure that the film contracts uniformly without causing any damage to the door’s surface or components. This stage ensures a snug, secure fit that protects the door from external elements.

2.4 Final Removal and Inspection

Once the door has been fully packaged, it moves to the outfeed section, where it can be manually removed or transferred to storage or shipping. At this stage, operators often conduct a final inspection to ensure that the packaging is free from defects and that the door is fully protected.

3. Key Benefits of an Automatic Door Packing Line

Investing in an automatic door packing line provides numerous advantages for manufacturers. From enhanced efficiency to improved safety, these systems are designed to optimize the packaging process and ensure that every door is packaged to the highest standard.

3.1 Increased Efficiency

One of the most significant benefits of an automatic door packing line is the dramatic improvement in efficiency. With the ability to process up to 120 doors per hour, these systems can handle large volumes of doors quickly and consistently. This not only reduces the time spent on packaging but also allows manufacturers to meet higher production demands without sacrificing quality.

3.2 Consistent Packaging Quality

Manual packaging is prone to inconsistencies, which can lead to damaged products and dissatisfied customers. Automatic packing lines, on the other hand, deliver consistent, high-quality packaging every time. The film is applied with the same tension and precision for each door, ensuring that every package is uniform and secure.

3.3 Enhanced Product Protection

The primary function of any packaging system is to protect the product during transportation and storage. Automatic door packing lines excel in this area, providing superior protection against dust, moisture, and minor impacts. The snug, shrink-wrapped film ensures that the door is fully enclosed and shielded from external elements, reducing the risk of damage.

3.4 Reduced Labor Costs

By automating the packaging process, companies can significantly reduce labor costs associated with manual packaging. With fewer workers needed to handle the packaging process, companies can allocate their labor resources more effectively, leading to cost savings and improved productivity.

3.5 Improved Safety

Manual packaging can be hazardous, especially when dealing with large, heavy products like doors. Automatic packing lines reduce the risk of workplace injuries by automating much of the heavy lifting and movement required during the packaging process. This leads to a safer working environment and fewer incidents of injury.

4. Safety Features of Automatic Door Packing Lines

Safety is a top priority in any manufacturing environment, and automatic door packing lines are designed with this in mind. These systems are equipped with a range of safety features to protect both the product and the operators.

4.1 Emergency Stop Systems

Most automatic packing lines are equipped with emergency stop systems, which allow operators to quickly halt the machine in the event of an issue. This ensures that any potential problems can be addressed immediately, preventing damage to the product or injury to the operator.

4.2 Safety Sensors

Safety sensors are another important feature of automatic door packing lines. These sensors detect when a door is not properly aligned or when there is an obstruction in the machine, automatically pausing the packaging process until the issue is resolved.

4.3 Temperature Control in Shrinking Tunnel

The shrinking tunnel is a critical stage of the packaging process, and temperature control is essential for ensuring that the film shrinks uniformly without damaging the door. Automatic packing lines are equipped with precise temperature controls to ensure that the heat applied during this stage is optimal for both shrinkage and product safety.

5. Customization Options for Automatic Door Packing Lines

One of the key benefits of automatic door packing lines is their customizability. These systems can be tailored to meet the specific needs of different manufacturers, ensuring that the packaging process is optimized for the type and size of door being produced.

5.1 Adjustable Film Tension and Sealing

Manufacturers can adjust the film tension and sealing settings on their packing lines to ensure that the film is applied with the right amount of tension for each product. This ensures that the film is neither too loose nor too tight, providing the perfect fit for maximum protection.

5.2 Customizable Conveyor Speeds

The speed of the conveyor can also be customized to match the pace of the production line. Faster conveyor speeds allow for higher throughput, while slower speeds may be necessary for more delicate products.

5.3 Compatibility with Various Film Types

Automatic door packing lines can also be configured to work with different types of packaging films, including shrink wrap, stretch film, and protective plastic. This flexibility allows manufacturers to choose the best material for their specific application.

6. Industries That Benefit from Automatic Door Packing Lines

While automatic door packing lines are primarily used in the door manufacturing industry, they can also benefit a wide range of other sectors. Any industry that produces large, heavy products that require secure packaging can benefit from the efficiency and protection offered by these systems.

6.1 Construction Industry

In the construction industry, automatic door packing lines are essential for packaging doors, windows, and other building materials. These systems ensure that products are well-protected during transit, reducing the risk of damage and ensuring that they arrive at the job site in perfect condition.

6.2 Furniture Manufacturing

Furniture manufacturers can also benefit from automatic packing lines, especially for large items like wardrobes, cabinets, and doors. The automated packaging process ensures that these products are securely wrapped and protected from dust, moisture, and impacts during storage and transport.

6.3 Home Improvement Retailers

For home improvement retailers that sell large products like doors and windows, automatic packing lines offer a way to streamline the packaging process and ensure that products are well-protected for customers.

7. Conclusion

In today’s competitive manufacturing environment, investing in an Automatic Door Packing Line is no longer optional — it’s essential. These systems not only improve the efficiency and consistency of the packaging process but also enhance product protection, reduce labor costs, and improve workplace safety. Whether you’re a door manufacturer or operate in a related industry, an automatic packing line can help you stay ahead of the competition and meet the growing demands of your customers.

By understanding how these systems work and the benefits they provide, companies can make informed decisions about incorporating them into their operations, ultimately leading to higher productivity and profitability.