The rotary arm pallet wrapping machine with conveyor automatic film cutting and clamping is an advanced packaging solution designed for efficient and reliable pallet wrapping operations. Here’s a comprehensive description:

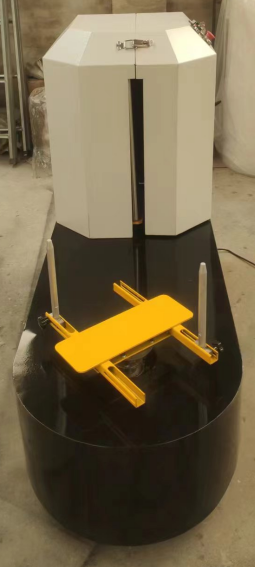

The machine features a rotating arm mechanism mounted on a robust frame, which revolves around the stationary load. This design eliminates the need for pallet rotation, making it ideal for unstable or heavy loads. The integrated powered roller conveyor system enables smooth pallet movement through the wrapping zone, supporting continuous operation.

Key technical features include:

Automated film cutting and clamping system

PLC-controlled operations with touch screen interface

Adjustable wrapping parameters (speed, tension, overlap)

Multiple wrapping programs for different load requirements

Film pre-stretch system (up to 250%) Wrapping height capacity up to 2000mm

Safety features comprise: Emergency stop buttons

Obstacle detection sensors

CE certification compliance

The machine offers various wrapping patterns including single/double wrap, top sheet application, and reinforcement wraps. The automatic film cutting and clamping system ensures clean film cuts and secure attachment to the load, eliminating manual intervention. This results in consistent wrap quality and improved operational efficiency while reducing labor costs and material waste.