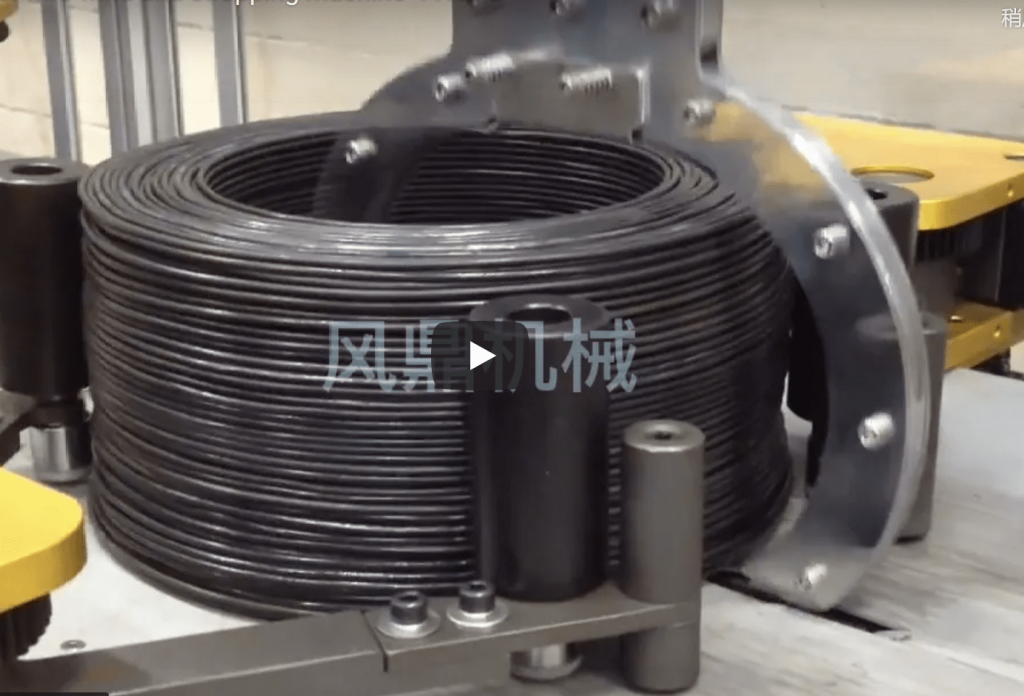

Pipe coil winding and strapping machine

This is a video for pipe coil winding and strapping line.

Manual vs. Automated Packaging: The Future of the Automatic Pipe Coiling and Strapping Machine

In the fast-paced world of manufacturing, packaging plays a crucial role. Whether it’s ensuring product safety or optimizing logistics, the choice between manual and automated systems can greatly impact a business’s efficiency. This article will explore the nuances of manual versus automated packaging, focusing on the future of the automatic pipe coiling and strapping machine.

Introduction to Packaging Systems

Packaging is more than just wrapping products; it’s a complex process that influences storage, transportation, and overall product quality. With the rise of automation, businesses face the critical decision of choosing between manual and automated solutions.

What is Manual Packaging?

Manual packaging involves human labor to handle, wrap, and secure products. While it offers flexibility and can be cost-effective for small-scale operations, it has limitations in terms of speed and consistency.

Advantages of Manual Packaging

- Flexibility: Manual packaging allows for customization and handling of unique or delicate items that machines may struggle with.

- Lower Initial Investment: For startups or small businesses, the lower cost of manual packaging can be attractive compared to the high upfront expense of automation.

Disadvantages of Manual Packaging

- Inconsistency: Human error can lead to variations in packaging quality, affecting product safety and customer satisfaction.

- Labor Costs: Over time, the ongoing costs of manual labor can outweigh the initial savings, especially in high-volume operations.

What is Automated Packaging?

Automated packaging uses machinery to handle the packaging process, offering speed and consistency. As technology advances, automated systems are becoming more sophisticated and accessible.

Advantages of Automated Packaging

- Efficiency: Automation significantly increases production speed, allowing businesses to meet high demand with ease.

- Consistency and Quality: Machines deliver uniform results, which is crucial for maintaining product standards.

- Reduced Labor Costs: Automating repetitive tasks frees up human resources for more strategic roles within the company.

Disadvantages of Automated Packaging

- High Initial Costs: The investment in machinery and setup can be prohibitive for smaller businesses.

- Maintenance and Technical Issues: Automated systems require regular maintenance and can be prone to technical issues, which might disrupt production.

The Future of Automatic Pipe Coiling and Strapping Machines

As industries evolve, so do the technologies surrounding them. The future of pipe coiling and strapping machines is promising, with several trends shaping the landscape.

Trend 1: Integration with Smart Technologies

The integration of smart technologies such as IoT and AI is transforming how these machines operate. Real-time data collection and analysis enable predictive maintenance, reducing downtime and enhancing efficiency.

Trend 2: Sustainability and Energy Efficiency

With a growing focus on sustainability, manufacturers are developing machines that consume less energy and use recyclable materials for packaging. This not only reduces costs but also aligns with environmental goals.

Trend 3: Customization and Flexibility

Modern machines are designed to handle a variety of materials and sizes, offering greater flexibility. This adaptability is crucial for businesses looking to diversify their product offerings.

Comparing Manual and Automated Systems in Pipe Coiling

Speed and Efficiency

Automated machines far outpace manual methods in terms of speed. They can coil and strap pipes in a fraction of the time, enabling faster turnaround and increased productivity.

Cost-Effectiveness

While manual systems may seem cheaper initially, automated systems provide better long-term savings. Reduced labor costs and higher throughput make automation a wise investment.

Quality and Consistency

The precision of automated systems ensures consistent quality, reducing the likelihood of defects and improving customer satisfaction. Manual methods, meanwhile, are prone to human error and inconsistency.

Safety and Ergonomics

Automation enhances workplace safety by minimizing the need for human intervention in hazardous tasks. This leads to fewer workplace injuries and a better working environment.

Implementing Automated Systems: Challenges and Solutions

Transitioning to an automated system can be daunting. Here are some challenges businesses might face and potential solutions:

Challenge 1: High Initial Investment

Solution: Consider financing options or leasing equipment to spread out costs. Evaluate the long-term ROI to justify the investment.

Challenge 2: Integration with Existing Processes

Solution: Work with experts to ensure seamless integration. Pilot testing can help identify potential issues before full-scale implementation.

Challenge 3: Training and Workforce Adaptation

Solution: Provide comprehensive training programs to help employees adapt to new technologies. Encourage a culture of continuous learning to ease the transition.

Conclusion

In the debate between manual and automated packaging, the future clearly leans towards automation. With advancements in technology, automated pipe coiling and strapping machines offer unmatched efficiency, consistency, and safety. Businesses that embrace these innovations position themselves for success in an increasingly competitive market. As we move forward, the focus should be on integrating smart, sustainable, and flexible solutions to meet evolving industry demands.