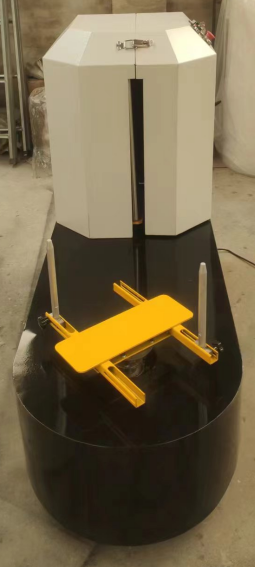

A pallet wrapper with a weighing scale is an integrated system designed for both wrapping and weighing palletized goods efficiently. This machine typically includes a base with a built-in scale for weight measurements, a turntable for rotating the pallet during the wrap process, and an upright structure that houses the film delivery system. By combining the processes of wrapping and weighing, this machine streamlines workflow, enhances accuracy in logistics, and optimizes freight operations by ensuring that cargo weight complies with transportation regulations.

The parameters below do not 100% match the equipment in the video. For exact specifications, please contact us.

- Type: Fully Automatic

- Year of Manufacture: 2023

- Condition: New

- Maximum Pallet Size: Length: 1500mm; Width: 1500mm; Height: 2500mm

- Wrapping Speed: Up to 25 wraps per minute

- Weighing Capacity: Up to 2000kg with a precision of +/- 1kg

- Film Type Compatibility: PE, pre-stretched film, netting

- Power Requirements: 240V, 50Hz, three phase

- Machine Dimensions: Length: 2800mm; Width: 1800mm; Height: 2800mm

- Machine Weight: Approximately 1200kg

- Warranty: 3 years

- Origin: Made in Italy

- Shipping: Available for international shipping

- Display: LED display for weight and operation settings

- Additional Features: Automatic height detection, programmable wrapping sequences

Applications for the pallet wrapper with weighing scale:

- Manufacturing Plants: Streamlined Packing Process

In a manufacturing setting, the pallet wrapper with a weighing scale serves a dual function. It not only securely wraps loads up to 1500mm by 1500mm but also weighs them with a maximum capacity of 2000kg. This feature is invaluable for ensuring compliance with shipping standards and avoiding overloading penalties. The accurate and streamlined process reduces the need for separate weighing, which speeds up the packing process and reduces labor costs. - Logistics and Shipping: Accurate Freight Data

The integration of weighing capabilities in the pallet wrapper allows logistics companies to obtain accurate weight data for their freight without additional equipment or steps. This accuracy is crucial for optimizing container space and ensuring that shipments meet legal weight requirements and avoid fines. The efficient operation of the machine, capable of handling up to 25 wraps per minute, enables faster cargo turnaround times, enhancing overall supply chain efficiency. - Agricultural Sector: Protection and Compliance

In the agricultural sector, where goods often require netting to maintain ventilation, the pallet wrapper with weighing scale adjusts to use suitable materials like netting while providing the necessary protection and stability during transport. The ability to wrap and weigh large bales or produce boxes ensures that agricultural products are kept within weight limits for road transport, reducing the risk of non-compliance with transportation laws and ensuring product integrity upon arrival.