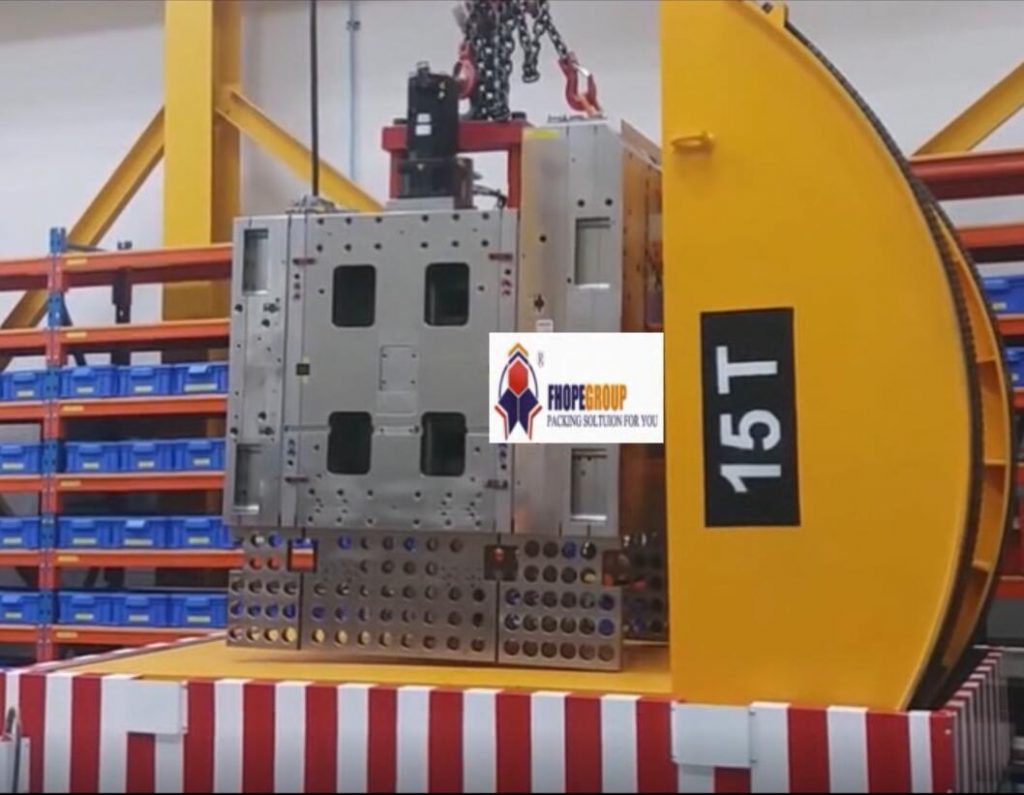

Hydraulic tilter with pressing top for board bundle

This is a vedio for hydraulic tilter with pressing top for board bundle.

The Differences Between Hydraulic Tilter for Board Bundles with and Without Pressing Top

In the world of industrial handling and material management, hydraulic tilters play a crucial role in ensuring safe and efficient operations. They are primarily used to tilt, rotate, and reposition heavy and large objects like board bundles, coils, or other bulky materials. However, when it comes to board bundle tilting specifically, there are two main categories of tilters: hydraulic tilters with a pressing top and hydraulic tilters without a pressing top.

Understanding the differences between these two types of tilters is essential for industries that require precision, safety, and efficiency in handling large board bundles. In this in-depth article, we will explore the key distinctions, advantages, and best-use cases for each type of hydraulic tilter.

What is a Hydraulic Tilter?

Before diving into the specific differences, it’s important to understand what a hydraulic tilter is. A hydraulic tilter is a machine designed to tilt or rotate heavy objects, typically up to 90 or 180 degrees, using hydraulic power. They are commonly used in industries like steel, paper, wood, and manufacturing to handle heavy loads in a safe and controlled manner.

Tilting is often necessary for loading or unloading processes, as well as for repositioning materials to make them more accessible for further processing or transportation. Hydraulic tilters are preferred for their ability to handle large and heavy loads with minimal manual labor, reducing the risk of injury and damage.

Why Are Hydraulic Tilters Important for Handling Board Bundles?

Board bundles, especially those made from wood, metal, or composite materials, are heavy, bulky, and often awkward to move or reposition manually. Without the proper equipment, handling these bundles can lead to accidents, product damage, and inefficiencies in the production process.

Hydraulic tilters help to streamline this process by providing a safe and efficient way to tilt and move board bundles with minimal effort. They are particularly important in industries where precision and safety are paramount, such as in lumber yards, furniture manufacturing, and construction material production.

Now that we have a better understanding of what hydraulic tilters are and why they are important, let’s explore the specific differences between hydraulic tilters with a pressing top and hydraulic tilters without a pressing top.

Hydraulic Tilter with Pressing Top: What Is It?

A hydraulic tilter with a pressing top is a specialized tilter that comes equipped with an additional feature: a pressing mechanism located at the top of the machine. This pressing top applies downward pressure on the load being tilted, typically on board bundles, to hold them securely in place during the tilting process.

Key Features of Hydraulic Tilter with Pressing Top:

- Pressing Mechanism: The most notable feature is the pressing top itself, which is a mechanical arm or plate that presses down on the board bundle to prevent movement or shifting during tilting.

- Enhanced Load Stability: The pressing top ensures that the load remains stable and does not slide or tip over during the tilting process.

- Hydraulic Control: Like all hydraulic tilters, the pressing top operates using a hydraulic system, which allows for precise control over the amount of pressure applied.

- Safety Features: Because the pressing top holds the load in place, it significantly reduces the risk of accidents caused by shifting or falling bundles.

Advantages of Hydraulic Tilter with Pressing Top:

- Increased Safety: One of the primary advantages of having a pressing top is the enhanced safety it provides. By holding the board bundle in place, the pressing top prevents any movement or shifting that could lead to accidents or damage to the load.

- Better Load Control: The pressing top offers greater control over the load, ensuring that it remains securely in place during the entire tilting process. This is particularly important when dealing with uneven or irregularly shaped bundles.

- Versatility: This type of tilter is ideal for handling a wide variety of materials, including board bundles that may be prone to slipping or shifting, such as those made from smooth or slippery materials.

- Improved Efficiency: With the pressing top keeping the load stable, operators can work more quickly and confidently, knowing that the load is secure.

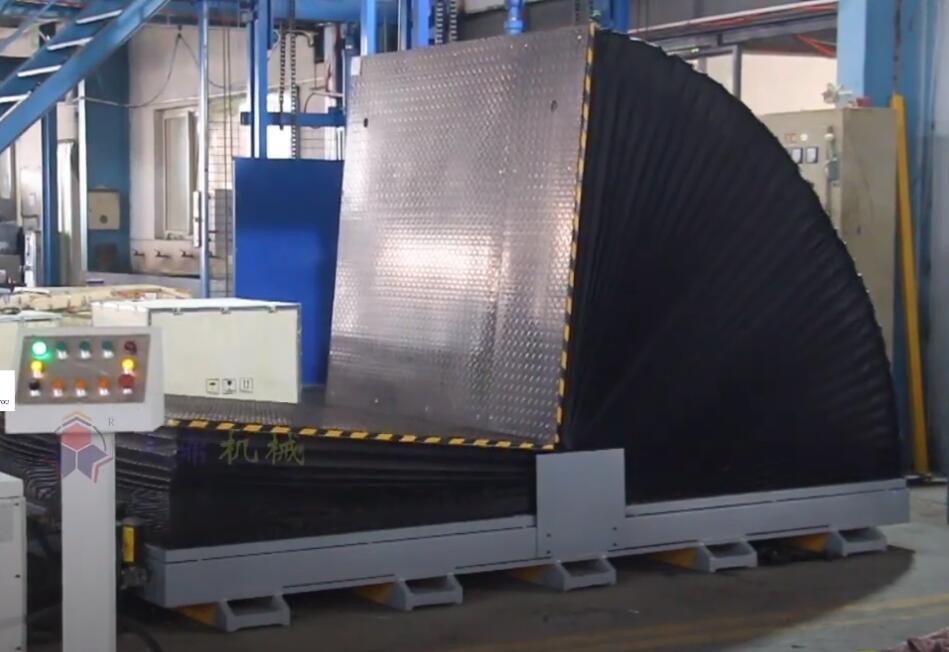

Hydraulic Tilter without Pressing Top: What Is It?

A hydraulic tilter without a pressing top is a more basic version of the hydraulic tilter. It lacks the pressing mechanism found in the other type, relying solely on the tilting platform to move the load. While these tilters are still highly effective for tilting and repositioning board bundles, they do not offer the same level of load security as tilters with a pressing top.

Key Features of Hydraulic Tilter without Pressing Top:

- Tilting Platform: The primary feature is the tilting platform itself, which lifts and tilts the load at the desired angle.

- Hydraulic Power: Like its counterpart, this tilter uses hydraulic systems to provide smooth and controlled tilting motion.

- No Pressing Mechanism: The absence of a pressing top means that the load is not held in place by any additional pressure during tilting.

Advantages of Hydraulic Tilter without Pressing Top:

- Cost-Effective: Hydraulic tilters without a pressing top tend to be more affordable than their counterparts, making them a great option for businesses with tight budgets.

- Simple Operation: With fewer components, these tilters are often easier to operate and maintain, which can be an advantage in environments where simplicity and reliability are key.

- Suitable for Stable Loads: If the board bundles being handled are stable and unlikely to shift during tilting, a tilter without a pressing top may be sufficient for the task.

- Space Efficiency: These tilters often have a smaller footprint due to the lack of a pressing mechanism, which can be beneficial in facilities with limited space.

Key Differences Between Hydraulic Tilters with and without Pressing Top

Now that we’ve explored each type of hydraulic tilter individually, let’s take a closer look at the key differences between the two:

1. Load Stability

- With Pressing Top: The pressing top ensures that the load remains stable during the entire tilting process, preventing any movement or shifting.

- Without Pressing Top: Load stability relies solely on the friction between the load and the tilting platform, meaning there is a higher risk of the load shifting or falling if it is not properly secured.

2. Safety

- With Pressing Top: These tilters offer enhanced safety due to the pressing mechanism, which holds the load in place and reduces the risk of accidents.

- Without Pressing Top: While still safe when used properly, tilters without a pressing top do not offer the same level of load security, which could lead to accidents in certain situations.

3. Cost

- With Pressing Top: The additional pressing mechanism makes these tilters more expensive, but they offer greater load control and safety.

- Without Pressing Top: These tilters are more cost-effective, making them a good choice for businesses with lower budgets or for applications where additional load security is not required.

4. Complexity of Operation

- With Pressing Top: The pressing top adds an extra layer of complexity to the operation, requiring operators to manage both the tilting and pressing functions.

- Without Pressing Top: These tilters are simpler to operate, with fewer components to control, making them easier to use and maintain.

5. Best Suited For

- With Pressing Top: Ideal for handling loads that are uneven, slippery, or prone to shifting during tilting. This makes them a good choice for industries where load stability is a top priority.

- Without Pressing Top: Best suited for stable loads that are unlikely to shift during tilting, such as tightly bound or evenly balanced board bundles.

Which Tilter Is Right for Your Business?

When deciding between a hydraulic tilter with a pressing top and one without a pressing top, there are several factors to consider:

1. Type of Load

- If you are handling unstable or irregularly shaped board bundles, a hydraulic tilter with a pressing top is the better choice, as it will provide the additional load stability you need.

- For stable, evenly balanced loads, a tilter without a pressing top may be sufficient, and you can save on both the initial investment and operational costs.

2. Safety Requirements

- If safety is a major concern in your facility, especially if your board bundles are prone to shifting, you should opt for a tilter with a pressing top. The added security of the pressing mechanism can help prevent workplace accidents.

- In environments where the risk of load shifting is low, a tilter without a pressing top may still provide adequate safety.

3. Budget

- Hydraulic tilters with pressing tops are generally more expensive due to the added complexity of the pressing mechanism. If your budget allows, the added safety and control may be worth the investment.

- If you are looking for a more cost-effective solution, a tilter without a pressing top can still provide excellent performance for stable loads, without the additional expense.

4. Space Constraints

- Hydraulic tilters with pressing tops tend to be larger and require more space due to the additional pressing mechanism. Ensure that your facility has enough room to accommodate one before making a purchase.

- If space is limited, a tilter without a pressing top may be a better option, as these machines typically have a smaller footprint.

Conclusion

Both hydraulic tilters with a pressing top and those without offer unique advantages depending on the type of load you are handling, your safety requirements, and your budget. The key difference lies in the load stability and control provided by the pressing top, which makes it ideal for handling unstable or slippery board bundles. On the other hand, tilters without a pressing top are more cost-effective and simpler to operate, making them a good choice for stable loads that are unlikely to shift during tilting.

Ultimately, the right choice for your business will depend on your specific operational needs. If you prioritize safety and load control and are handling complex or irregularly shaped bundles, a hydraulic tilter with a pressing top is the way to go. However, if your loads are stable and you’re looking for a more affordable solution, a tilter without a pressing top may be the best fit.

No matter which type you choose, investing in a high-quality hydraulic tilter will enhance your material handling processes, improve safety, and increase operational efficiency.