How does a steel coil strapping machine strap with two belts at one time?

Steel coil packaging is a demanding process that requires efficiency and stability. Traditional single-belt strapping machines often struggle to meet the industry's speed requirements. If your operation relies on high-speed, secure strapping, an advanced dual-belt system might be the ideal solution.

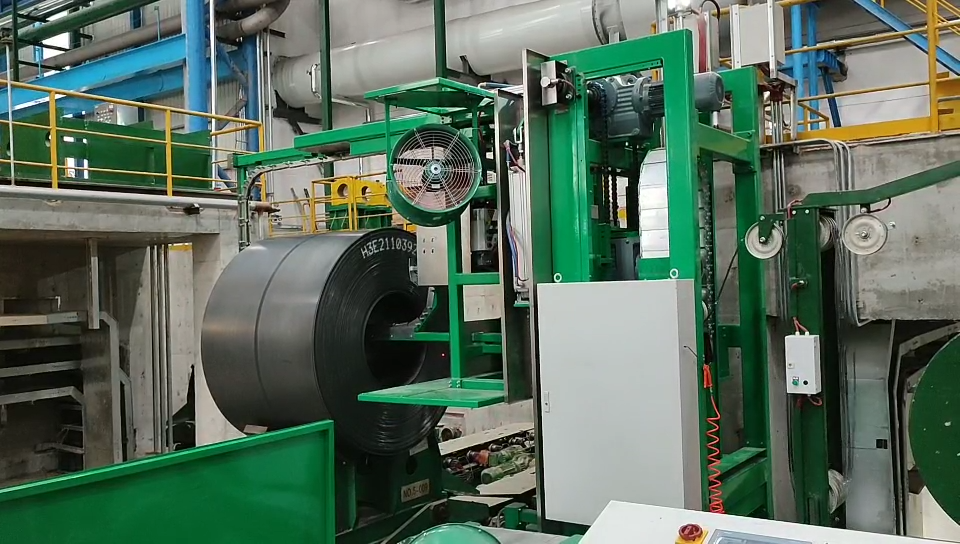

A steel coil strapping machine with two belts straps coils simultaneously, increasing efficiency and stability. The dual-belt system ensures even tension and alignment, reducing damage and enhancing handling speed. This setup is ideal for automated, high-output production lines, significantly improving packaging performance.

For companies handling large volumes of steel coils, optimizing packaging speed without compromising security is essential. Let’s explore how dual-belt strapping machines achieve this balance.

Efficient Dual-Belt Strapping: Enhancing Steel Coil Packaging Speed and Stability?

Strapping steel coils is a crucial step in their handling and transportation. Slow or inconsistent strapping can cause bottlenecks and safety risks. A two-belt strapping machine addresses these issues, delivering higher efficiency and stability.

A dual-belt strapping machine uses two strapping heads to apply two belts simultaneously. This method significantly reduces strapping time and ensures uniform tension across the coil, improving load stability and preventing shifting during transit.

Why Dual-Belt Strapping is More Efficient?

A dual-belt system offers advantages that a single-belt machine cannot match. The key benefits include:

| Feature | Single-Belt Strapping | Dual-Belt Strapping |

|---|---|---|

| Speed | Slower, one strap at a time | Faster, two straps at once |

| Load Stability | Uneven tension, risk of shifting | Balanced tension, better load security |

| Automation | Limited automation potential | High compatibility with automated lines |

| Coil Protection | Higher risk of localized stress | Even distribution of force |

By strapping two belts simultaneously, this machine ensures that the coil remains stable and secure, even under high-speed operations. This method is especially beneficial for large-scale steel processing plants where downtime is costly.

How Dual-Belt Strapping Works: Mechanism and Benefits of Simultaneous Steel Coil Securing?

Traditional strapping machines apply one belt at a time, often causing misalignment and inconsistent tension. A dual-belt system eliminates these issues by securing both straps at once, improving efficiency and safety.

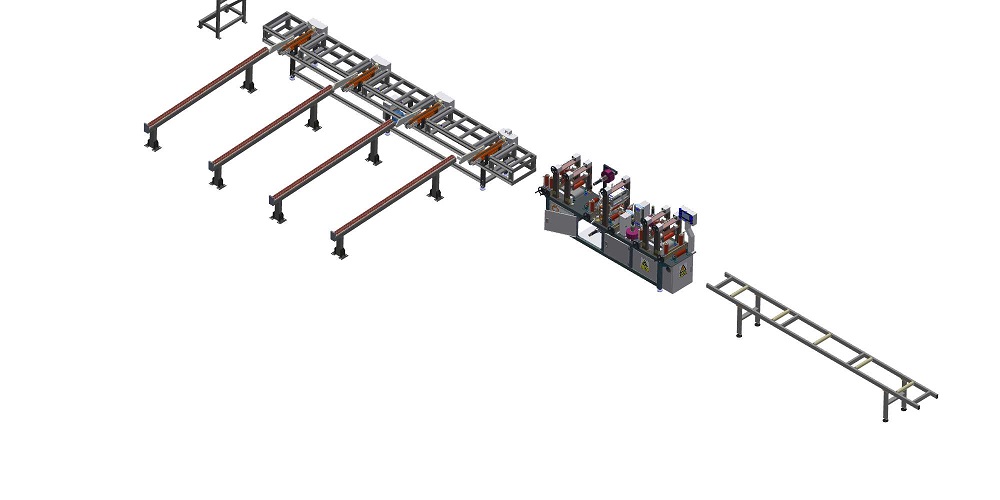

Dual-belt strapping machines operate using two independent strapping heads working simultaneously. Each head applies a strap to opposite sides of the coil, ensuring uniform force distribution. This prevents deformation, enhances coil stability, and supports high-speed packaging.

The Technology Behind Dual-Belt Strapping

To understand why this system is effective, let's break down the core components:

| Component | Function |

|---|---|

| Dual Strapping Heads | Two heads apply straps at the same time, ensuring even tension. |

| Automated Positioning System | Aligns the straps accurately, reducing misalignment. |

| Tension Control Mechanism | Adjusts strap tension based on coil size and weight. |

| Fast-Sealing Technology | Uses heat or ultrasonic welding for secure and durable seals. |

| PLC Control System | Fully automated, allowing integration into production lines. |

This system minimizes human intervention, ensuring precision and reducing labor costs. By applying straps simultaneously, it increases packaging speed without compromising security.

Optimizing Steel Coil Handling: The Advantages of a Two-Belt Strapping Machine?

Handling steel coils efficiently requires a balance of speed and precision. Traditional methods often fall short in keeping up with modern production demands. A two-belt strapping machine improves packaging efficiency and ensures better coil stability.

A two-belt strapping machine enhances coil handling by reducing packaging time, improving safety, and ensuring uniform load security. It integrates with automated lines, reducing manual intervention and optimizing workflow. This results in faster throughput and minimized damage risk.

Why is a Two-Belt Strapping Machine the Best Choice?

Steel coil handling presents unique challenges. A two-belt system addresses these with advanced technology and automation. Here’s how:

| Benefit | Description |

|---|---|

| Speed | Straps coils twice as fast as single-belt machines. |

| Load Balance | Even tension application prevents coil shifting. |

| Automation | Fully automated strapping reduces labor requirements. |

| Durability | Advanced tension control prevents strap breakage. |

| Integration | Compatible with conveyor and robotic systems. |

With growing demand for faster, safer, and more reliable packaging, dual-belt strapping machines offer a future-proof solution for steel coil manufacturers.

Conclusion

A dual-belt steel coil strapping machine provides significant advantages over traditional single-belt systems. By strapping two belts simultaneously, it enhances speed, stability, and automation, making it an essential tool for modern coil packaging operations. Investing in this technology ensures higher efficiency, reduced labor costs, and improved safety in steel coil handling.