Optimizing Packaging Efficiency with the Versatile Wire Coil Wrapping Machine

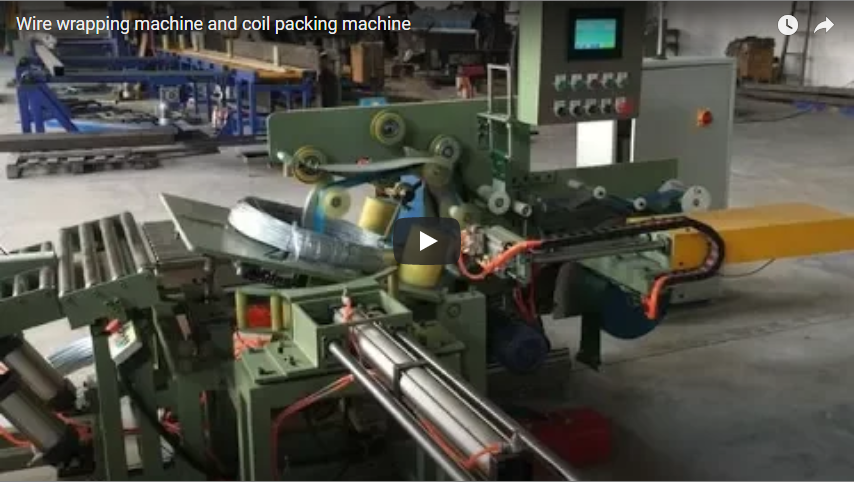

In the realm of industrial packaging, efficient machinery that adapts to diverse product specifications is crucial. The wire coil wrapping machine exemplifies such versatility, particularly in its capacity to handle various packaging materials and accommodate different sizes and weights of steel wire products. This article explores how the wire coil wrapping machine enhances efficiency and protection in the packaging process, ensuring that steel wire coils are securely prepared for transportation or storage.

Tailored Packaging Solutions

The wire coil wrapping machine stands out for its ability to utilize a range of packaging materials including paper, film, and knitted belts. These materials are not only versatile but can be precisely tailored to match the specific dimensions and weight requirements of the steel wire coils. For example, copper tube coils with an outer diameter of 500-800mm, a width of 100-300mm, and an inner diameter of 400-600mm can be efficiently wrapped using a dual-layer approach combining paper and stretch film.

Technological Integration and Automation

At the heart of the machine’s operation is its advanced automation system, which includes a programmable logic controller (PLC), human-machine interface (HMI), and the use of inverters and sensors. These components ensure that the packaging material is applied evenly and securely, wrapping each coil tightly to prevent any movement that could lead to damage during handling.

The automated functions of the machine significantly enhance the packing speed and consistency, reducing the need for manual intervention and thereby lowering labor costs and potential errors. This system not only speeds up the process but also ensures that each coil is wrapped with precision, adhering to the strictest industry standards, as evidenced by its CE certification.

Protection and Efficiency

The primary goal of the wire coil wrapping machine is to provide maximum protection. By customizing the wrapping material and process for each type of wire coil, the machine ensures that each product is shielded against environmental factors and mechanical damage during transportation or storage. The combination of paper and stretch film offers a robust defense against moisture, dust, and abrasion, safeguarding the metal's integrity and finish.

Conclusion

The wire coil wrapping machine represents a significant advancement in packaging technology for the steel industry. With its ability to customize wrapping materials and its integration of cutting-edge automation, the machine offers a solution that is both efficient and effective. Manufacturers and distributors of steel wire products can rely on this machine to maintain the quality and condition of their products, from production to delivery. As industries continue to seek cost-effective and reliable packaging solutions, machines like the wire coil wrapping machine are pivotal in meeting these complex demands, ensuring that products arrive in perfect condition to customers around the globe.

info@fhopepack.com