Enhancing Protection and Efficiency: A Deep Dive into Horizontal Orbital Wrappers for Doors and Panels

Introduction: The Challenge of Packaging Large, Flat Products

In manufacturing and logistics, the secure and efficient packaging of large, flat, or elongated items such as doors, panels, windows, and lumber presents unique challenges. Ensuring product integrity during handling, storage, and transportation is paramount, yet traditional packaging methods can be labor-intensive, inconsistent, and fail to provide adequate protection. Enter the horizontal orbital wrapping machine – a sophisticated engineering solution designed specifically to address these issues.

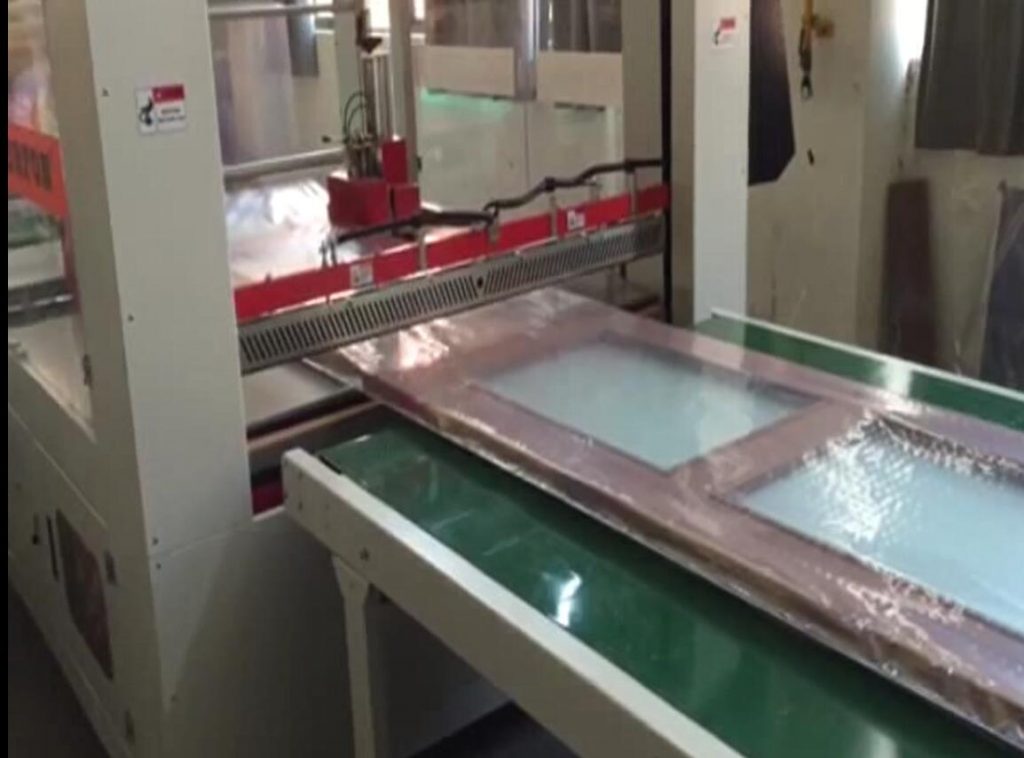

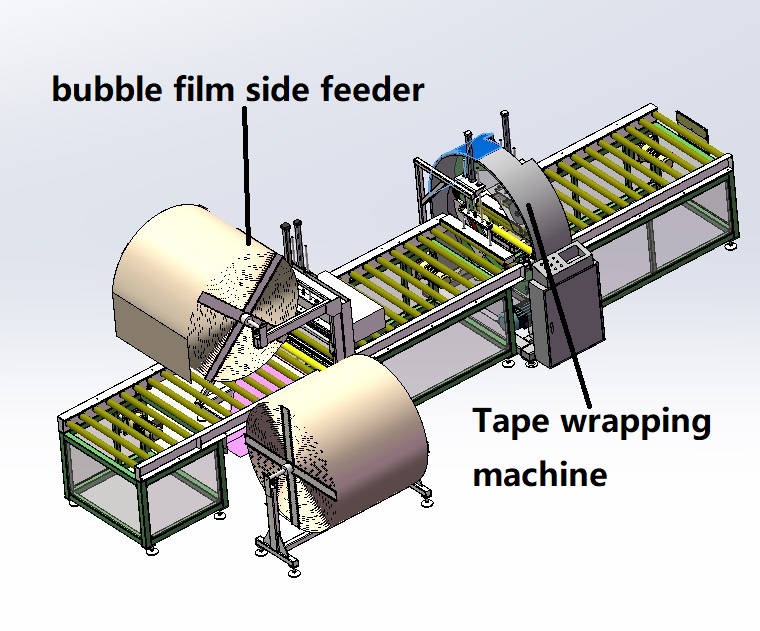

The Technology Explained: Inside the Horizontal Orbital Wrapper

A horizontal orbital wrapping package machine utilizes a distinctive mechanism where the product moves horizontally on conveyors through a rotating ring assembly. This ring carries a film dispensing carriage that orbits around the product, applying layers of stretch film securely.

Core Components and Operation:

- Rotating Ring Assembly: The heart of the machine, engineered for smooth, high-speed rotation while maintaining balance. Its diameter dictates the maximum cross-section of the product that can be wrapped.

- Film Carriage & Pre-Stretch Unit: This unit holds the film roll and typically incorporates a powered pre-stretch system. Research published in packaging technology journals highlights that pre-stretching film (often up to 250-300%) significantly enhances film yield, reduces material costs, and improves load containment forces – a critical factor validated by transport simulation studies.

- Conveyor System: Motorized conveyors (roller or belt) feed the product into the wrapping ring and transport the wrapped item out, ensuring a continuous and automated flow. Synchronization between conveyor speed and ring speed is crucial for consistent overlap and wrap quality.

- Clamping, Cutting, and Sealing: Advanced models feature automatic systems to clamp the film start, cut the film upon cycle completion, and seal the tail end to the package, often using heat or pressure methods, minimizing manual intervention. This automation draws on principles outlined in numerous patents related to packaging machinery efficiency (e.g., optimizing cycle time and film management).

- Control System (PLC & HMI): Programmable Logic Controllers (PLCs) manage the wrapping parameters, cycle sequences, and safety interlocks. Human-Machine Interfaces (HMIs), often touchscreens, allow operators to easily set parameters like wrap counts, tension levels, ring/conveyor speeds, and diagnose issues.

Key Advantages and Operational Benefits

Implementing horizontal orbital wrapping technology delivers tangible benefits across the supply chain:

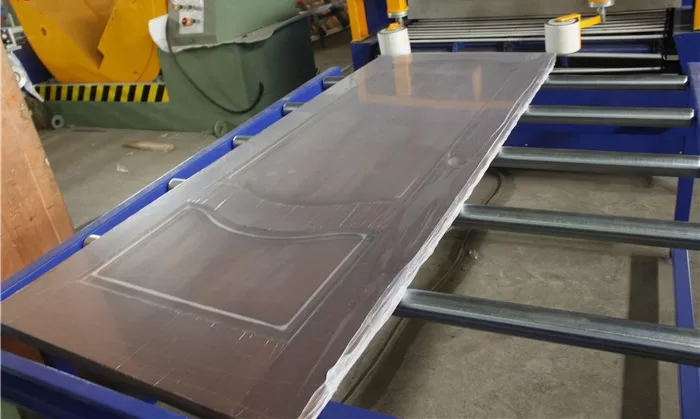

Enhanced Product Protection:

- Full Encapsulation: Provides a complete, tight wrap around all six sides (if programmed), shielding products from dust, moisture, scratches, and surface damage.

- Uniform Tension: Precisely controlled film tension ensures consistent load stability, preventing shifting during transit, a common cause of damage highlighted in logistics industry reports.

- Edge Protection: The orbital application naturally reinforces vulnerable edges and corners.

Improved Operational Efficiency:

- Increased Throughput: Significantly faster than manual wrapping or traditional vertical methods for long products. Cycle times are optimized based on product length and desired wrap layers.

- Reduced Labor Costs: Automation minimizes the need for manual wrapping labor, freeing up personnel for other tasks and reducing ergonomic risks.

- Consistency: Machine application guarantees repeatable wrap quality, unlike manual methods prone to variability.

Material Optimization & Cost Savings:

- Pre-Stretch Savings: As noted, powered pre-stretch maximizes film utilization, leading to direct cost reductions in consumables. Industry benchmarks often show film usage reductions of 50% or more compared to non-pre-stretch methods.

- Reduced Waste: Automated cutting and sealing minimize film tail waste.

Versatility:

- Adaptable Parameters: Easily adjustable settings accommodate a wide range of product dimensions (length, width, height) and shapes.

- Broad Application: Suitable for doors, panels, windows, countertops, aluminum extrusions, lumber, pipes, textiles, and more.

Technical Specifications & Considerations

While specific parameters vary by model and manufacturer, typical specifications include:

- Maximum Product Dimensions: Defines the upper limit for length, width, and height (or ring opening diameter).

- Ring Speed: Measured in RPM (Revolutions Per Minute), influencing throughput.

- Conveyor Speed: Measured in m/min (meters per minute), adjustable to match production flow.

- Film Specifications:

- Type: LLDPE (Linear Low-Density Polyethylene) stretch film.

- Width: Common sizes like 500mm.

- Thickness: Typically 17-35 microns.

- Pre-Stretch Ratio: Variable, often up to 300%.

- Control System: PLC brand (e.g., Siemens, Allen-Bradley), HMI size and features.

- Power Requirements: Voltage, phase, and total power consumption.

- Optional Features: Top sheet dispensers (for added top protection), integrated weighing systems, specialized conveyor types, automatic corner protection applicators.

Industry Impact and Applications

Horizontal orbital wrappers are increasingly indispensable in sectors requiring robust packaging for bulky or elongated goods:

- Building Materials: Packaging doors, windows, insulation panels, flooring, timber, and profiles.

- Furniture Manufacturing: Wrapping assembled or flat-packed furniture components.

- Metals Industry: Securing pipes, tubes, extrusions, and sheet metal.

- Textiles: Wrapping large rolls of fabric or carpet.

The adoption of this technology aligns with broader industry trends towards automation, efficiency improvement, and sustainable packaging practices (through material reduction). As noted in publications like Packaging World and Modern Materials Handling, optimizing secondary packaging is a key lever for reducing overall supply chain costs and enhancing customer satisfaction through damage reduction.

Conclusion: A Strategic Investment in Packaging Excellence

The horizontal orbital wrapping machine represents more than just packaging equipment; it's a strategic investment in product integrity, operational efficiency, and cost control. By leveraging advanced engineering principles, automation, and material science (specifically film pre-stretching), these systems provide a superior solution for protecting large and challenging products throughout the distribution lifecycle. For manufacturers and distributors of doors, panels, and similar items, embracing this technology is key to maintaining competitiveness and delivering products in pristine condition. Evaluating the specific needs against the capabilities of a modern horizontal orbital wrapping package machine can unlock significant improvements in packaging performance and bottom-line results.