This automatic horizontal wrapping and packing line is designed to bundle and wrap various sized aluminum rods and profiles for shipping and storage. The machine creates uniform, securely wrapped packages of aluminum angles, channels, flats, rounds and other aluminum extruded shapes.

The power conveyors at the infeed and outfeed ensure a continuous high speed operation. Aluminum parts of different sizes and shapes are fed onto the conveyor which aligns and spaces them correctly for bundling.

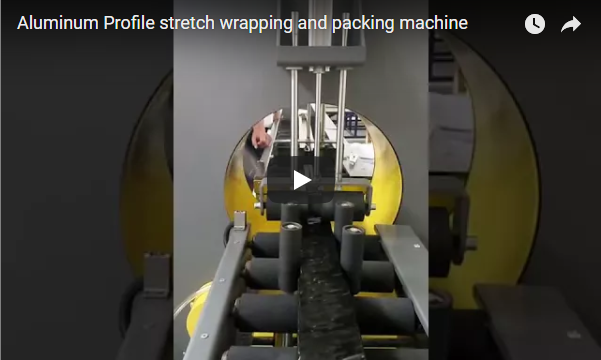

The film wrapping unit then wraps stretch film around the bundles to hold the aluminum parts firmly together. The wrapping unit controls the tension and placement of the stretch film to form tight, uniform bundles without deforming or damaging the aluminum profiles and rods inside. Different wrapping cycles and patterns can be programmed to suit various part sizes and bundle configurations.

The packing machine can be customized to accommodate different package shapes and sizes up to the maximum handling capacity. Package weights can range from a few kilograms to hundreds of kilograms depending on bundle size and part thickness.

This full-automatic wrapping and packing line creates consistent, robust bundles of aluminum profiles for shipping and distribution. The infeed and outfeed conveyors enable a high throughput operation while the controlled film wrapping eliminates bundle deformation and part damage. The machine's design flexibility accommodates various parcel dimensions and part specifications within the maximum capacity.