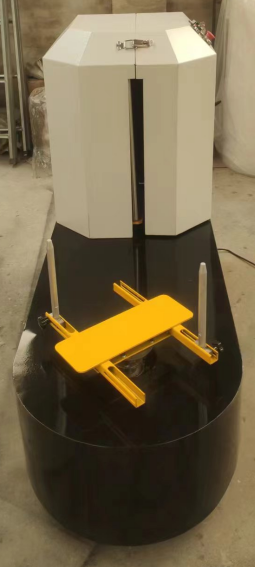

The Full-automatic M-type pallet wrapping Machine with Film Cutter & Holding System is an advanced equipment tailored for wrapping large pallet loads automatically, ensuring efficiency and security in packing processes, particularly in logistics and distribution. This machine is distinguished by its “M” shape layout that allows for front and rear loading, suitable for conveyor integration. It features a pre-stretch film carriage that optimizes film usage, an automatic film cutter for seamless operation, and a film holding unit that stabilizes the start of the wrapping cycle. Automation enhances the performance and reliability of the entire wrapping process, designed for heavy-duty applications where quick and secure packaging is vital.

The parameters below do not 100% match the equipment in the video. For exact specifications, please contact us.

- Type: Full-Automatic Pallet Wrapper

- Model: FHG-M100

- Year of Manufacture: 2023

- Condition: New

- Maximum Pallet Size: Length: 1200mm; Width: 1200mm; Height: 2400mm

- Wrapping Capacity: Up to 40 pallets per hour

- Machine Dimensions: Length: 5000mm; Width: 4000mm; Height: 2800mm

- Film Cutter: Integrated automatic system

- Film Delivery System: Pre-stretch up to 300%

- Power Requirements: 480V, 60Hz, three phase

- Control System: Programmable Logic Controller (PLC) with touchscreen

- Load Capacity: Up to 2000kg

- Safety Features: Photo-eye pallet height sensor, emergency stop

- Warranty: 5 years

- Conveyor Speed: Adjustable up to 12 m/min

- Film Roll Specifications: Width: 500mm; Thickness: 20 microns

Application 1: High-volume Production Environments

The Full-automatic M-type pallet wrapping machine is particularly beneficial in high-volume production settings such as beverage or food manufacturing. Its capability to wrap up to 40 pallets per hour ensures continuous operation without downtime. The integrated film cutter and holding system significantly reduce the time involved in the wrapping process, enhancing overall production line efficiency. This helps in maintaining the pace in high-demand periods, thereby contributing to meeting market demands more effectively.

Application 2: Secure Transport Preparation for Distribution Centers

In distribution centers, securing pallets for safe transport is a priority, and the Full-automatic M-type machine excels in this area. The ability to tightly wrap and secure diverse loads helps in minimizing damages during transit, which is crucial for items that are prone to shifting or are fragile. The automated system ensures consistent wrapping quality, reducing the risk associated with human error and improving load stability during shipping.

Application 3: Streamlined Workflow for Warehousing Operations

Warehousing operations benefit from the Full-automatic M-type pallet wrapping machine by optimizing the storage and shipping process. The machine’s high efficiency and consistent pallet wrapping performance enable faster readiness of goods for shipping or storage, thereby reducing bottleneum in warehouse throughput. The automatic film cutter and holding mechanism ensure that each pallet is uniformly wrapped and ready for the next step in the supply chain, supporting streamlined operations and effective space management.