Steel coil packaging has always been a labor-intensive process. From manual handling to time-consuming tasks, traditional methods are inefficient and costly. But with advancements in automation, the packaging process is evolving. Today, smart machines are reducing the need for human labor, cutting costs, and increasing efficiency. In this article, we’ll dive into the transformation of steel coil packaging and what the future holds.

Steel coil packaging has long relied on manual labor, leading to high costs and inefficiencies. Today, automation is changing the game. New technology is streamlining the process, reducing human intervention, and improving overall performance. As industries move toward smarter solutions, steel coil packaging is seeing massive improvements.

The next section will discuss the challenges of traditional steel coil packaging and why a shift to automation is necessary for greater efficiency and cost savings.

The Challenges of Traditional Steel Coil Packaging: High Labor Costs and Inefficiencies

Steel coil packaging has traditionally been a manual, labor-intensive process. From wrapping coils to stacking and securing, the job requires multiple steps and significant human involvement. The reliance on manual labor brings about several challenges, including high labor costs and slower production times.

One of the biggest challenges with traditional steel coil packaging is the cost. Labor costs make up a significant portion of the overall packaging cost. Additionally, manual processes can be prone to errors, leading to rework and delays in production. Not only does this affect the bottom line, but it also slows down the supply chain, ultimately leading to inefficiencies.

Automation offers a way out of these challenges. By automating the packaging process, manufacturers can reduce labor costs and eliminate the risk of human error. Smart machines can complete tasks more efficiently, improve accuracy, and ensure consistency. In this section, we’ll explore the details of how automation is transforming steel coil packaging.

Manual Labor vs. Automated Solutions

In traditional packaging lines, workers are tasked with manually handling heavy steel coils. This requires careful lifting, positioning, and wrapping, all of which take time and increase the chance of injury. Workers also have to deal with the repetitive nature of the work, leading to fatigue and errors.

On the other hand, automated packaging systems use advanced technology to perform tasks more quickly and accurately. These systems can automatically wrap coils, detect the size and shape of the product, and adjust packaging settings accordingly. This not only reduces human labor but also speeds up the overall process, boosting productivity.

| Traditional Packaging | Automated Packaging |

|---|---|

| High labor costs | Reduced labor costs |

| Increased risk of errors | Fewer errors, higher accuracy |

| Slow production time | Faster production |

| Requires manual handling | Machines handle heavy lifting |

| Fatigue and injury risks | Safer working environment |

By shifting to automated solutions, companies can not only save on labor costs but also streamline their operations and boost productivity.

Automation in Steel Coil Packaging: How Technology Revolutionizes the Process

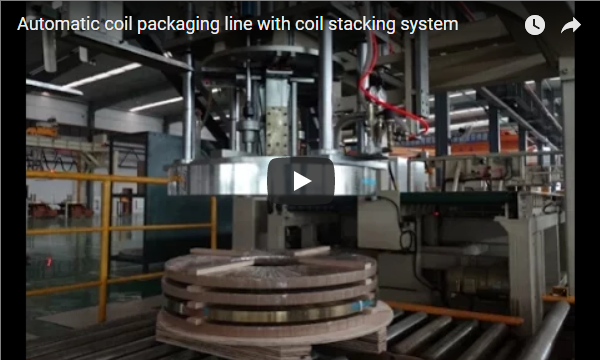

Automation in steel coil packaging is more than just replacing manual labor. It involves the integration of advanced technologies like robotics, sensors, and AI to create smarter and more efficient systems. These technologies are revolutionizing the way packaging is done.

How does automation improve steel coil packaging? The integration of robots, conveyors, and intelligent systems allows for a much faster, safer, and more efficient packaging process. Sensors can monitor the quality of each coil, ensuring that it is properly packaged without human intervention. AI-powered systems can analyze data to optimize the process in real-time, improving productivity and reducing waste.

With automation, packaging systems are not just doing the job faster; they are doing it with more precision and consistency. This ensures that each steel coil is packaged to the highest standard, reducing the risk of damage during transport and storage.

Robotics and AI Integration

Robots are increasingly being used in packaging lines to perform tasks such as loading, wrapping, and securing the coils. These machines can work at high speeds and operate continuously without breaks, unlike human workers. They are also designed to handle the heavy lifting and repetitive movements that would otherwise lead to fatigue and errors in manual systems.

AI plays a key role in optimizing the process. It can monitor machine performance, predict maintenance needs, and even adjust packaging settings based on real-time data. This reduces downtime and ensures that the packaging process is running at maximum efficiency.

The impact of AI and robotics on steel coil packaging is significant. These technologies not only improve efficiency but also reduce costs and enhance safety. Here’s a look at the key benefits:

| Benefits of Automation | Impact on Steel Coil Packaging |

|---|---|

| Faster production | Reduced packaging time and higher output |

| Improved accuracy | Fewer errors, consistent quality |

| Lower labor costs | Reduced need for manual labor |

| Predictive maintenance | Reduced downtime and repair costs |

| Safety | Less physical strain on workers |

By incorporating AI and robotics, manufacturers can ensure that their packaging lines are both cost-effective and high-performing.

Future Trends in Steel Coil Packaging: Smart Solutions for a More Sustainable and Efficient Industry

The future of steel coil packaging is bright, with ongoing advancements in automation and technology. As industries move toward more sustainable practices, the packaging process will continue to evolve, focusing on smarter and more energy-efficient solutions.

What does the future hold for steel coil packaging? In the coming years, we can expect further integration of smart technologies. The use of machine learning, big data, and advanced sensors will enable packaging systems to make real-time adjustments, ensuring optimal performance. These innovations will help companies minimize waste, reduce energy consumption, and improve overall sustainability.

The trend toward sustainability is also influencing packaging materials. There is a growing demand for eco-friendly packaging options that are both cost-effective and reduce the environmental impact. As a result, we can expect the development of new packaging materials and systems that align with global sustainability goals.

Sustainable Packaging Materials and Processes

As sustainability becomes a top priority, the steel coil packaging industry is increasingly adopting eco-friendly materials and processes. For example, biodegradable or recyclable films are being used to wrap coils instead of traditional plastic materials. These alternatives not only reduce environmental impact but also help companies meet regulatory standards and consumer expectations.

Moreover, the move toward energy-efficient machinery is another trend shaping the future of packaging. New automated systems are designed to consume less energy, thereby reducing costs and environmental footprints. In addition, companies are investing in renewable energy sources to power their operations, further reducing their reliance on fossil fuels.

| Sustainability Trend | Impact on Steel Coil Packaging |

|---|---|

| Eco-friendly materials | Reduced environmental impact |

| Energy-efficient machinery | Lower energy costs and carbon footprint |

| Recycling and waste reduction | Less waste generated, eco-friendly practices |

As smart technologies continue to advance, we can expect more energy-efficient, sustainable, and cost-effective solutions to emerge in the steel coil packaging industry.

Conclusion

The transformation of steel coil packaging from a labor-intensive process to a smart, automated system has had a profound impact on the industry. By embracing automation and advanced technologies, companies are improving efficiency, reducing costs, and enhancing safety. As we look to the future, the continued evolution of packaging systems promises even more sustainable and smarter solutions. The journey toward smarter, more efficient steel coil packaging is well underway, and it’s an exciting time for the industry.