In today’s fast-paced manufacturing world, automation is the key to efficiency. But how can companies improve their wire coiling and strapping processes to enhance productivity while reducing labor costs? Let’s dive into how the latest technologies in wire coiling and strapping lines are revolutionizing industrial packaging.

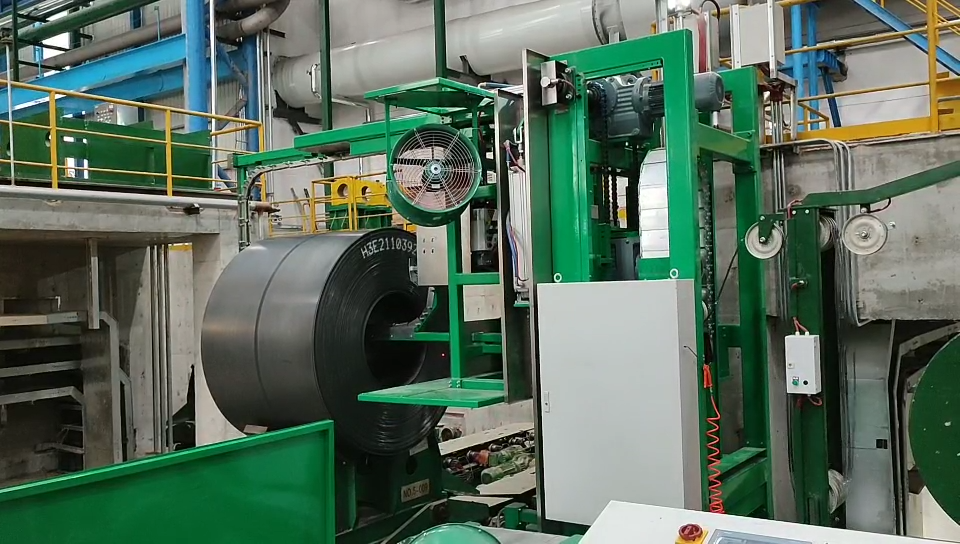

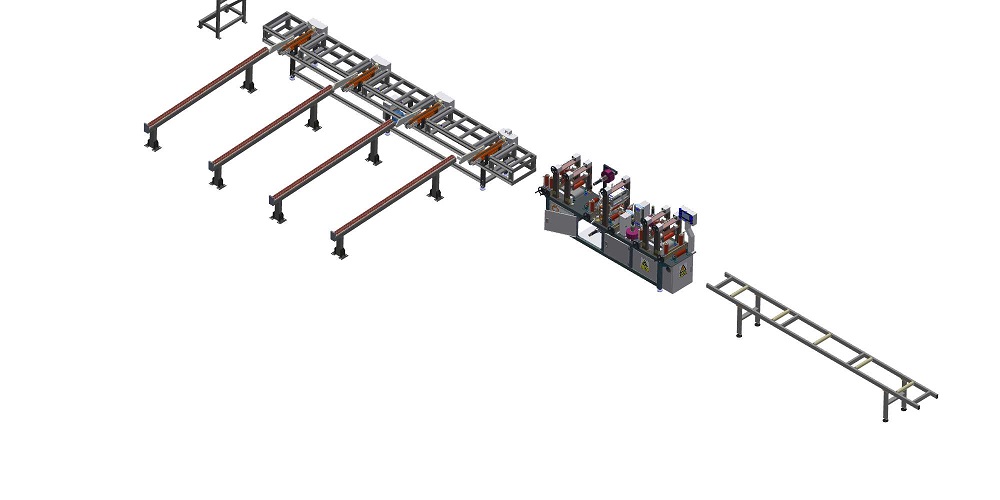

Wire coiling and strapping lines are essential for industries like automotive and construction, where steel coils must be safely handled and efficiently packaged. Modern automated systems streamline these processes, boosting productivity and ensuring consistency.

As we continue exploring the evolution of industrial packaging solutions, let’s look deeper into how advanced wire coiling and strapping lines are transforming operations. These systems not only reduce manual labor but also minimize errors, leading to a more reliable and cost-effective packaging solution.

Understanding the Wire Coiling Process: Efficiency and Precision?

Every manufacturing line benefits from improving efficiency. The wire coiling process is no exception. How does automation improve the precision and speed of this process?

Wire coiling has traditionally been a manual task, requiring careful handling and time-consuming procedures. But today, automated wire coiling systems offer high precision, ensuring consistent coil sizes, and reducing waste.

Why is Precision Crucial in Wire Coiling?

When it comes to wire coiling, precision isn’t just a luxury—it’s a necessity. Automating this process helps ensure that each coil is wound consistently, eliminating human error that could result in substandard products. This leads to fewer defects and less rework. Additionally, the automation process can handle different coil sizes and wire types, which would be difficult to manage manually.

The Role of Automation in Increasing Efficiency

Automation not only increases accuracy but also speeds up the process. Automated systems can coil wire at a much faster rate than a manual process, increasing overall throughput. This is essential in industries that require high-volume production without sacrificing quality.

Benefits of Reduced Waste and Errors

With improved precision, there’s less chance of errors during the wire coiling process. This reduces material waste, as the coils are precisely wound to the correct specifications. Over time, these small savings in material costs can add up significantly, improving the overall efficiency of your operation.

Strapping Line Technology: Enhancing Packaging and Logistics?

Packaging solutions play a crucial role in ensuring that the final product reaches customers in perfect condition. How do strapping lines contribute to this process?

Strapping lines are designed to secure wire coils tightly, ensuring safe handling and transportation. With advanced technology, these lines not only improve the strength of the strapping but also enhance the overall packaging process.

The Mechanics of a Strapping Line

Strapping lines are designed to use automated machines to wrap PET belts or steel bands around wire coils. This process ensures that the coils are compacted securely for transportation. These systems are programmed to adjust the tension on the strapping, ensuring it is neither too tight nor too loose. This precision prevents the coils from shifting or being damaged during transport.

Key Advantages of Using Strapping Lines

Strapping lines bring numerous advantages to the packaging process. They significantly reduce labor costs by automating what would normally be a manual task. Additionally, they offer a higher level of consistency and reliability, ensuring that every coil is strapped securely in the same way.

Flexibility in Packaging Solutions

One of the most significant benefits of automated strapping systems is their flexibility. Whether you’re dealing with large steel coils or smaller wire rolls, these machines can be adjusted to accommodate different sizes and types of products. This flexibility ensures that you can handle a variety of packaging requirements without needing separate equipment for each product.

Key Benefits of Wire Coiling and Strapping in Industrial Applications?

What are the main benefits of implementing automated wire coiling and strapping systems in your operation? Let’s explore the advantages they bring to industrial applications.

Automated wire coiling and strapping lines provide key benefits such as increased production efficiency, reduced labor costs, improved safety, and higher-quality output. These systems are an investment that leads to long-term savings.

Enhanced Productivity Through Automation

The primary benefit of automating the wire coiling and strapping process is enhanced productivity. Manual handling of wire coils is time-consuming, and automation reduces the time needed for each step. This leads to faster production cycles and more output per hour. The consistency and speed of these systems make them a valuable asset for any industrial operation.

Cost-Effectiveness and Return on Investment

While automated systems can be a significant initial investment, they offer a substantial return over time. By reducing labor costs, minimizing material waste, and increasing production speeds, these systems pay for themselves over the long term. Businesses that embrace automation in their wire coiling and strapping processes often see improved profitability due to these savings.

Better Workplace Safety and Reduced Risk

Manual wire handling can be hazardous, particularly when dealing with heavy coils. Automation helps eliminate these risks by handling the most physically demanding tasks. This not only ensures a safer working environment but also minimizes the chance of workplace injuries. The reduced need for manual intervention allows workers to focus on other critical tasks, boosting overall productivity.

Innovative Features of Modern Wire Coiling and Strapping Systems?

What makes today’s wire coiling and strapping systems so innovative? Let’s take a look at the latest technological features and how they are changing the game.

Modern wire coiling and strapping systems come with several innovative features such as automatic coil counting, enhanced strapping tension control, and data integration for monitoring and optimizing production.

Automatic Coil Counting and Tracking

One of the most impressive features of modern systems is their ability to automatically count the length of wire being coiled. This ensures that each coil is consistent in size and meets the required specifications. By tracking the wire length, the system can also notify operators when the coil is complete, which helps prevent errors and reduces downtime.

Advanced Tension Control for Strapping

The tension of the strapping material is crucial for securing the coils. Too much tension can damage the coil, while too little won’t hold it tightly enough. Modern systems use advanced sensors and automated controls to ensure the ideal amount of tension for each coil. This guarantees a secure strap without risking damage to the product.

Data Integration for Optimization

Today’s coiling and strapping systems can be integrated with production management software. This allows manufacturers to monitor key metrics such as production speed, material usage, and system performance in real time. By analyzing this data, companies can identify areas for improvement, reduce downtime, and optimize the entire production process.

Conclusion

The latest advancements in wire coiling and strapping lines are transforming industrial packaging. With automation, companies can expect higher efficiency, improved safety, and significant cost savings. These systems are a smart investment for any business looking to streamline its operations and stay competitive in the modern manufacturing landscape.