Streamlining Steel Wire Handling: A Closer Look at the Economic Wire Wrapping and Coil Packing Machine

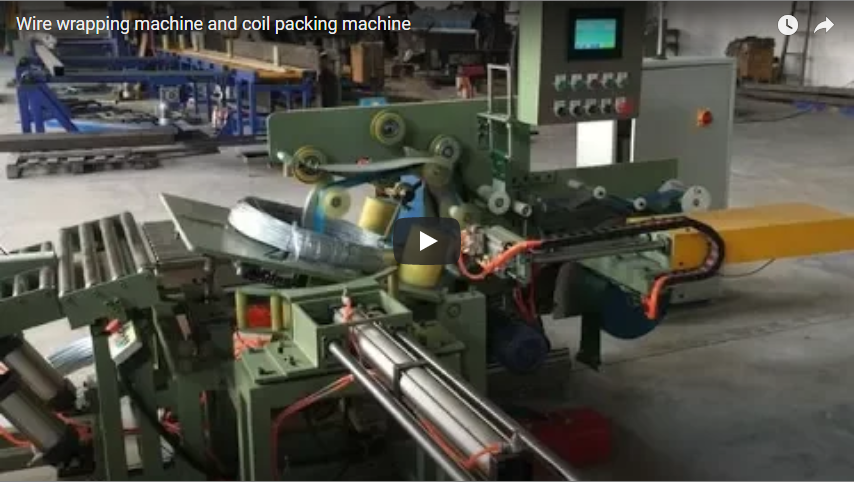

Handling and packaging heavy steel wire coils presents significant logistical and safety challenges across various industries. Ensuring these coils are securely wrapped and protected for storage or transport is crucial for maintaining product integrity and operational efficiency. The Economic Wire Wrapping and Coil Packing Machine emerges as a specialized, automated solution designed to address these very needs effectively.

This dual-function apparatus integrates distinct wrapping and packing units into a streamlined workflow. Let's delve deeper into its functionality and value proposition.

1. Operational Mechanics: Precision and Efficiency

The machine operates through a sequence designed for optimal efficiency:

- Loading: Coils are positioned onto a robust loading mechanism, designed to handle significant weight safely.

- Wrapping: A specialized wrapping unit encircles the wire coil with a protective film (like PE, PVC, or stretch film). Precision film dispensers ensure consistent tension and overlap, minimizing material waste while maximizing protection.

- Packing (Optional/Integrated): Following the wrapping, an integrated packing unit may further secure the coil, often using materials like polyethylene or shrink wrap, preparing it for final dispatch or storage.

- Control System: A compact, automated control system manages the entire process, ensuring high repeatability and reducing the need for manual intervention. This automation is key to the machine's "economic" value – boosting throughput while lowering labor costs.

2. Core Technical Specifications Overview

Understanding the machine's capabilities is essential. Below are typical parameters; however, customization is often possible.

-

Disclaimer: The parameters listed below serve as a general guideline and may not perfectly match the specific equipment shown in the video. For precise specifications tailored to your application, please contact us directly.

-

Machine Type: Economic Wire Wrapping and Packing Machine

-

Wire Diameter Compatibility: 1mm to 20mm (Versatile range for various wire types)

-

Maximum Coil Weight Capacity: 500kg (Suitable for substantial industrial coils)

-

Compatible Film Types: PE (Polyethylene), PVC, Stretch Film

-

Wrapping Speed: Up to 20 wraps per minute (Indicative of operational throughput)

-

Maximum Coil Outer Diameter: 1200mm

-

Packing Material Options: Polyethylene, Shrink Wrap

-

Power Requirements: 220V, 50Hz, Single Phase (Standard industrial power)

-

Approximate Machine Dimensions:

- Length: 2500mm

- Width: 1600mm

- Height: 2000mm

-

Safety Features: Equipped with Emergency Stop buttons and Safety Guards for operator protection.

3. Key Operational Benefits: More Than Just Wrapping

Investing in automated wrapping technology offers tangible advantages beyond basic packaging:

- Increased Throughput: Automating the wrapping process significantly speeds up packaging compared to manual methods, reducing bottlenecks in production or distribution lines.

- Enhanced Product Protection: Consistent, tightly applied wrapping shields wire coils from environmental factors like moisture and dust, as well as physical damage during handling and transit. My experience shows this drastically reduces rework or scrap costs associated with damaged goods.

- Improved Workplace Safety: Automating the handling and wrapping of heavy, potentially unwieldy coils minimizes manual lifting and manipulation, reducing the risk of musculoskeletal injuries for operators.

- Reduced Operational Costs: Beyond labor savings, optimized film usage and reduced product damage contribute to lower overall operating expenses. The "economic" nature of this machine often translates to a faster return on investment.

- Consistent Package Quality: Automation ensures every coil is wrapped to the same standard, providing a professional and uniform appearance vital for brand image and customer satisfaction.

4. Strategic Applications Across Industries

The versatility of the economic wire wrapping and coil packing machine makes it invaluable in several key sectors:

4.1 Electrical Wire Manufacturing

In the production of electrical wires – from standard residential wiring to complex cables for electronics – maintaining insulation integrity is paramount. This machine provides:

- Damage Prevention: Secure wrapping protects sensitive insulation from nicks and abrasions during handling and shipping.

- Efficient Bulk Handling: With speeds up to 20 wraps/minute and capacity for various diameters, manufacturers can rapidly process large volumes, ensuring timely order fulfillment.

- Environmental Protection: Tightly sealed wraps prevent moisture ingress, crucial for maintaining the electrical properties of the wire.

4.2 Construction Industry Logistics

Construction sites demand large quantities of steel wire (e.g., rebar tie wire, utility wire). Secure packaging is essential for:

- Safe Transport & Handling: Properly wrapped coils (up to 500kg) prevent dangerous unspooling during transit and on potentially chaotic job sites.

- Durability: Protective film shields the wire from weather exposure and rough handling conditions typical of construction environments.

- Reduced Waste: Secure packaging minimizes tangling and damage, ensuring the wire remains usable and reducing material waste on site.

4.3 Streamlining Wholesale Wire Distribution

For wholesale distributors, efficiency and presentation are key performance indicators. This machine facilitates:

- High-Volume Processing: Automation allows distributors to handle large inventories and process orders quickly and efficiently.

- Optimized Storage: Uniformly wrapped coils are easier to stack and store, maximizing warehouse space utilization.

- Enhanced Customer Satisfaction: Delivering well-protected, professionally packaged, and easy-to-handle coils improves the B2B customer experience and reinforces supplier reliability. From observation, distributors using such automation often report fewer damage claims and higher client retention.

5. Making the Right Choice

Selecting the ideal wire wrapping configuration depends on specific operational needs, including typical coil dimensions and weight, required throughput speed, preferred wrapping materials, and the level of automation desired. Considering these factors ensures the chosen machine aligns perfectly with your production or distribution requirements.

Conclusion

The Economic Wire Wrapping and Coil Packing Machine is more than just packaging equipment; it's a strategic tool for enhancing efficiency, safety, and product quality in any operation dealing with steel wire coils. By automating a critical process, it offers significant cost savings and operational improvements, making it a valuable asset across manufacturing, construction, and distribution sectors.

For more details on specific wire coil wrapping solutions:

https://www.fhopepack.com/Wire-coil-wrapping-machine/

To discuss your specific requirements, please contact us:

info@fhopepack.com