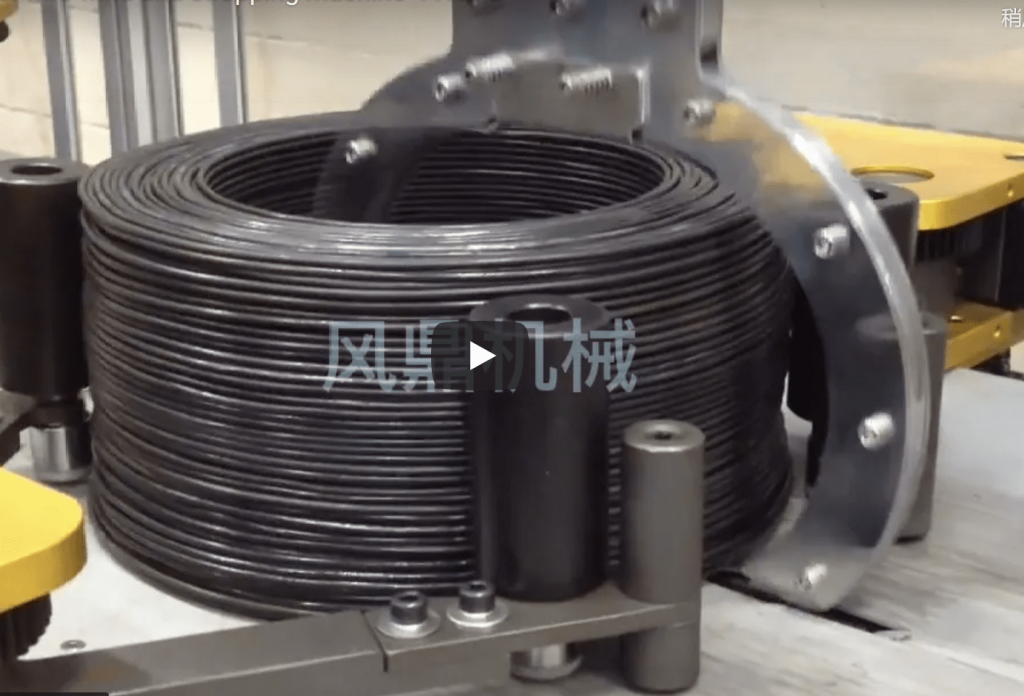

This is a video for coil packing machine with movable trolley .

Finding the Right Protective Packaging Solutions for Your Steel Coils

Steel coils are a vital resource for industries such as construction, automotive, and manufacturing. These heavy-duty materials are often exported or stored for extended periods, making protective packaging solutions essential to maintain their quality and integrity. Without proper packaging, steel coils are vulnerable to corrosion, scratches, moisture, and transport damage, which can lead to financial losses and delays in production.

Selecting the right packaging for steel coils is not just about safeguarding the material but also ensuring smooth handling, compliance with global shipping standards, and cost-effectiveness. In this guide, we’ll explore the best protective packaging solutions for steel coils, their importance, and how to choose the right methods for your business.

Table of Contents

- Why Is Protective Packaging Essential for Steel Coils?

- Common Challenges in Transporting and Storing Steel Coils

- Key Characteristics of an Ideal Protective Packaging Solution

- Popular Types of Coil Packaging Materials

- 4.1 Stretch Film

- 4.2 VCI (Volatile Corrosion Inhibitor) Paper

- 4.3 Laminated Kraft Paper

- 4.4 Metal Strapping

- The Role of Coil Wrapping Machines in Protective Packaging

- Benefits of Automated Packaging for Steel Coils

- Custom Packaging Solutions for Different Coil Sizes and Shapes

- Sustainability in Steel Coil Packaging

- Choosing the Right Packaging Partner for Your Needs

- Future Trends in Protective Packaging for Steel Coils

- Conclusion

1. Why Is Protective Packaging Essential for Steel Coils?

Steel coils are a high-value asset, and their quality is critical to downstream processes. Without proper packaging, they are susceptible to a range of issues, including:

- Rust and Corrosion: Steel is prone to oxidation when exposed to moisture, leading to rust that weakens its structural integrity.

- Mechanical Damage: During handling and transportation, steel coils can incur scratches, dents, or gouges, rendering them unsuitable for critical applications.

- Environmental Hazards: Dust, dirt, and UV exposure can degrade the surface quality of steel coils over time.

Protective packaging acts as a barrier, shielding steel coils from these risks while maintaining their pristine condition. Moreover, it ensures compliance with international shipping standards, which often mandate specific packaging requirements for heavy industrial materials.

2. Common Challenges in Transporting and Storing Steel Coils

Handling steel coils is no easy task, given their weight, size, and susceptibility to damage. Here are some of the common challenges faced by businesses:

- Heavy Weight and Large Dimensions: Steel coils can weigh several tons and vary in size, making them difficult to handle and package efficiently.

- Moisture Exposure: Humidity during storage or transit can lead to rusting if the packaging is not moisture-resistant.

- Movement During Transit: Improper securing of coils can result in shifting during transport, causing deformation or damage.

- Insufficient Packaging Materials: Using the wrong materials can lead to tearing, inadequate protection, or increased costs.

- Compliance Issues: Exporting steel coils internationally often requires adherence to specific packaging regulations, which can be a challenge without the right solutions.

Understanding these challenges is the first step in finding the right protective packaging solutions for your steel coils.

3. Key Characteristics of an Ideal Protective Packaging Solution

When choosing protective packaging for steel coils, it’s important to consider the following characteristics:

- Moisture Resistance: Packaging materials should provide strong protection against water and humidity to prevent rust.

- Durability: The packaging must withstand the rigors of handling, stacking, and transport without tearing or degrading.

- Custom Fit: Steel coils come in various sizes and shapes, so the packaging should be adaptable to ensure a snug fit.

- Ease of Application: Efficient packaging solutions should minimize labor and time during the wrapping or securing process.

- Cost-Effectiveness: Balancing quality and affordability is key for businesses looking to optimize their packaging processes.

By prioritizing these characteristics, you can select a solution that offers maximum protection while keeping operational costs in check.

4. Popular Types of Coil Packaging Materials

Protective packaging for steel coils involves a combination of materials designed to address specific risks. Here are some of the most commonly used options:

4.1 Stretch Film

Stretch film is a versatile and cost-effective solution used to wrap steel coils tightly. Its elasticity ensures a secure fit, while its barrier properties provide protection from dust, dirt, and moisture.

Advantages:

- Easy to apply using manual or automated wrapping machines.

- Transparent, allowing visibility of the product.

- Lightweight, reducing packaging weight during shipping.

4.2 VCI (Volatile Corrosion Inhibitor) Paper

VCI paper releases corrosion-inhibiting molecules that form a protective layer on the surface of the steel coil. This prevents rusting even in high-humidity environments.

Advantages:

- Ideal for long-term storage.

- Combines moisture protection with anti-corrosion properties.

- Environmentally friendly and recyclable.

4.3 Laminated Kraft Paper

Laminated kraft paper offers excellent abrasion resistance and can be used as an outer layer to protect steel coils from scratches and minor impacts.

Advantages:

- Durable and tear-resistant.

- Provides additional cushioning.

- Suitable for export packaging.

4.4 Metal Strapping

Metal strapping is used to secure steel coils during transportation, preventing movement that could cause damage.

Advantages:

- High tensile strength for heavy-duty applications.

- Ensures coils remain stable during transit.

- Compatible with automated strapping machines for efficiency.

5. The Role of Coil Wrapping Machines in Protective Packaging

Manual packaging methods are time-consuming and often inconsistent, especially for large steel coils. Coil wrapping machines are designed to automate the process, offering consistent and reliable protection.

These machines use advanced technology to wrap steel coils with precision, applying materials such as stretch film or VCI paper uniformly. Some machines are equipped with features like movable trolleys and two loading positions, making it easier to handle large coils.

By investing in a coil wrapping machine, businesses can significantly reduce labor costs, improve packaging quality, and enhance operational efficiency.

6. Benefits of Automated Packaging for Steel Coils

Automation is transforming the way steel coils are packaged. Here are some of the key benefits:

- Speed: Automated systems can package coils much faster than manual methods, increasing productivity.

- Consistency: Machines ensure uniform application of packaging materials, reducing errors and waste.

- Safety: Automation minimizes the need for manual handling, reducing the risk of workplace injuries.

- Cost Savings: By optimizing material usage and reducing labor requirements, automated packaging delivers long-term savings.

- Scalability: Automated systems can handle a variety of coil sizes and volumes, making them suitable for businesses of all scales.

7. Custom Packaging Solutions for Different Coil Sizes and Shapes

Steel coils come in various dimensions, from small rolls to large outer diameter coils. Custom packaging solutions are essential to accommodate this diversity.

Some key considerations for custom packaging include:

- Adaptable Wrapping Machines: Machines with adjustable settings can handle different coil sizes seamlessly.

- Protective Inserts: Foam or cardboard inserts can be added to secure irregularly shaped coils.

- Edge Protection: Reinforced corner protectors or plastic shields prevent edge damage during handling.

Custom solutions ensure that every coil receives the level of protection it requires, regardless of its size or shape.

8. Sustainability in Steel Coil Packaging

As industries move toward greener practices, sustainability is becoming a key focus in steel coil packaging. Businesses can reduce their environmental impact by:

- Using Recyclable Materials: Opting for eco-friendly options like VCI paper or biodegradable stretch film.

- Minimizing Material Waste: Automated systems ensure precise material usage, reducing excess waste.

- Energy-Efficient Machines: Investing in packaging machines designed for low energy consumption.

Sustainable packaging not only aligns with environmental goals but also enhances a company’s reputation as a socially responsible business.

9. Choosing the Right Packaging Partner for Your Needs

Finding the right packaging partner is crucial to implementing effective solutions. Look for a provider that offers:

- Comprehensive Services: From packaging materials to automated machines, a one-stop partner simplifies the process.

- Customization Options: Ensure they can tailor solutions to meet your specific coil packaging requirements.

- Technical Support: Reliable after-sales service and maintenance are essential for long-term success.

- Proven Expertise: Choose a company with a strong track record in the steel coil industry.

Collaborating with the right partner ensures you have access to the latest technologies and best practices in protective packaging.

10. Future Trends in Protective Packaging for Steel Coils

The future of steel coil packaging lies in the integration of smart technologies and sustainable practices. Innovations to watch for include:

- IoT-Enabled Machines: Real-time monitoring and analytics to optimize packaging processes.

- AI-Powered Systems: Predictive maintenance and automatic adjustments for maximum efficiency.

- Revolutionary Materials: Development of ultra-durable yet eco-friendly packaging materials.

By staying ahead of these trends, businesses can maintain a competitive edge in the ever-evolving steel coil industry.

11. Conclusion

Protective packaging is an indispensable part of handling steel coils, ensuring they remain in perfect condition throughout storage and transit. From stretch film and VCI paper to automated wrapping machines, the right solutions minimize risks, reduce costs, and improve operational efficiency.

As the industry moves toward automation and sustainability, businesses must adapt to stay competitive. Investing in high-quality protective packaging not only safeguards your steel coils but also enhances your brand’s reputation for reliability and excellence.

Choosing the right protective packaging is not just a necessity—it’s a strategic decision that drives long-term success in the steel coil industry.