In the bustling industrial landscape of Delhi, India, a service center has taken a significant leap forward in modernizing its steel coil handling operations. The introduction of an advanced coil stacking machine, coupled with automatic stacking programming, is set to transform the way heavy steel coils are managed, addressing critical safety concerns and enhancing operational efficiency.

The Challenge: Danger in Manual Coil Stacking

For years, the Delhi-based service center grappled with the inherent dangers of manually stacking steel coils. The process required workers to coordinate with crane operators, orchestrating a delicate dance of heavy machinery and multi-ton steel coils. As coils arrived on the conveyor, staff faced the daunting task of maneuvering these massive cylinders onto pallets – a procedure fraught with risk and physical strain. The potential for accidents loomed large, with even a minor misstep potentially leading to catastrophic consequences. It was clear that an automated solution was not just desirable; it was imperative for worker safety and operational continuity.

Tailored Solution: Precision Engineering Meets Customer Needs

Recognizing the unique challenges faced by the Delhi service center, our engineering team developed a customized coil stacking machine that addresses their specific requirements. The solution is designed to handle coils weighing up to 5 tons, with a stacking speed of 20-30 coils per hour – a significant improvement over manual operations. The system accommodates pallets sized 1200mm x 1200mm, with a versatile stacking height range of 100-1000mm, ensuring flexibility for various coil dimensions.

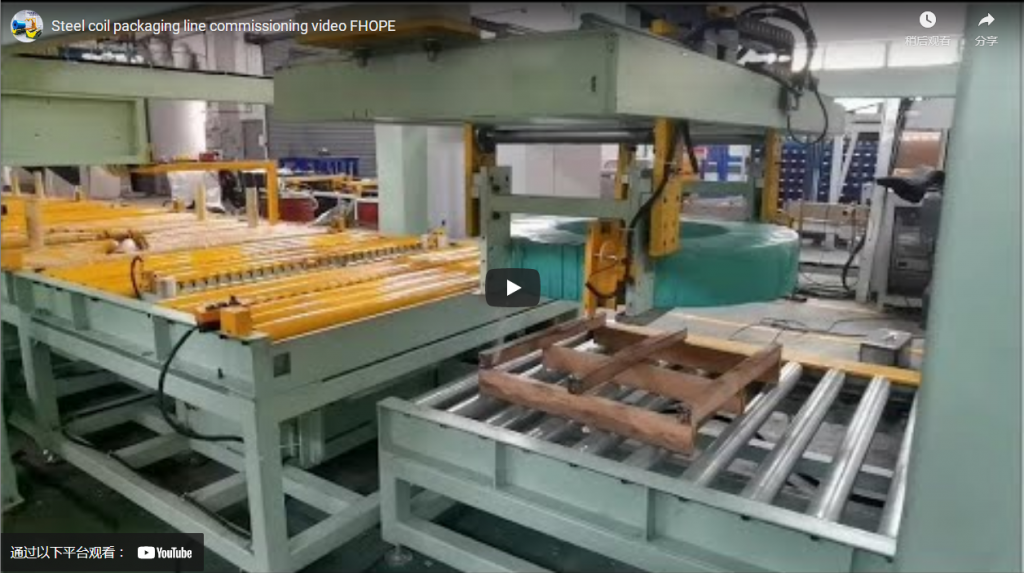

At the heart of the machine is a mechanical fork arm, engineered for precision lifting and placement of heavy coils. This robust mechanism eliminates the need for manual intervention in the most dangerous part of the stacking process. To ensure consistent and accurate stacking, the system incorporates advanced PLC and HMI controls, complemented by encoders that meticulously check and adjust coil height during the stacking process.

Key Features and Benefits: Safety, Efficiency, and Precision

The coil stacking machine boasts several features that directly address the challenges faced by the service center:

- Enhanced Safety: By automating the coil transfer from conveyor to pallet, the risk of accidents due to manual handling is virtually eliminated.

- Improved Stacking Accuracy: The encoder-based height checking system ensures that each coil is perfectly aligned, minimizing mismatches in vertical stacking.

- Increased Productivity: With a capacity to handle up to 30 coils per hour, the machine significantly boosts operational efficiency.

- Versatile Handling: The ability to accommodate wooden spacers (>40mm height) between coils adds flexibility to the stacking process, catering to various storage and transportation requirements.

- User-Friendly Interface: The intuitive HMI allows operators to monitor and control the stacking process with ease, reducing the learning curve and enhancing overall operational control.

Take the Next Step in Coil Handling Efficiency

Are you facing similar challenges in your steel processing facility? Our coil stacking machine could be the game-changing solution you need. Contact us today to schedule a personalized demonstration and see firsthand how this innovative technology can revolutionize your coil handling operations. Our team of experts is ready to provide you with detailed product specifications and discuss how we can tailor this solution to your specific needs.

Frequently Asked Questions:

- How does the coil stacking machine ensure consistent stacking quality?

The machine utilizes advanced encoders and PLC controls to precisely measure and adjust coil height during the stacking process, ensuring uniform and stable stacks. - Can the system handle coils of varying weights and dimensions?

Yes, the machine is designed to accommodate coils up to 5 tons in weight and can stack to heights ranging from 100mm to 1000mm, offering flexibility for different coil sizes. - What maintenance is required for the coil stacking machine?

While the system is designed for minimal maintenance, regular inspections of the mechanical fork arm, encoder systems, and control interfaces are recommended to ensure optimal performance and longevity.

info@fhopepack.com