In the bustling industrial landscape of Vietnam, wire rod factories face unique challenges in their production processes. One such factory has been grappling with inefficiencies in their wire rod compacting and packing operations, leading to increased labor costs, extended packing times, and safety concerns. Today, we introduce an innovative solution that promises to transform their workflow: the automatic wire coil compacting and strapping line.

The Challenge: Streamlining Wire Rod Packing

Our Vietnamese client’s semi-automatic wire rod packing machine has been a bottleneck in their production line, unable to integrate seamlessly for streamlined packing. This disconnect has resulted in a multitude of issues:

- Labor-intensive process requiring six workers per 8-hour shift

- Prolonged packing times hampering overall productivity

- Safety risks associated with manual handling of heavy wire coils

- High costs of strapping materials

Moreover, their current steel strapping machine, while able to use wire rod as a binding material, incurs substantial expenses in strapping materials.

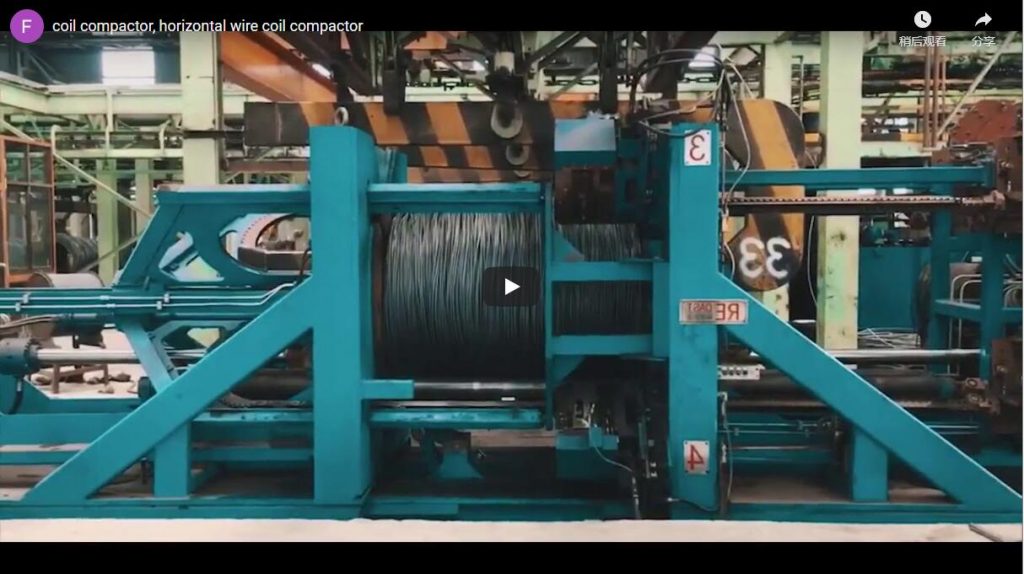

Customized Solution: Automatic Wire Compacting and Strapping Machine

To address these challenges head-on, we’ve developed a fully automatic wire compacting and strapping machine that uses wire rod as the strapping material. This bespoke solution is designed to integrate effortlessly with the client’s crane line, ensuring a smooth, continuous operation.

Key features of our system include:

- Adjustable compacting capabilities:

- Before compacting: 2000-2500mm width

- After compacting: 1500-1800mm width

- Flexible coil dimensions:

- Outer Diameter (OD): 1000-1400mm

- Inner Diameter (ID): 600-900mm

- Fully automatic operation requiring only one operator

- Seamless integration with existing crane lines

Benefits That Drive Efficiency and Cost Savings

Our automatic wire coil compacting and strapping line offers numerous advantages:

- Dramatic reduction in labor costs: from six workers to just one operator

- Significant time savings in the packing process

- Enhanced safety through automated handling

- Cost reduction by using wire rod as strapping material

- Improved product consistency and quality

- Increased overall production efficiency

The fully automated nature of our solution ensures consistent, high-quality results while minimizing human error and intervention.

Take the Next Step Towards Automation

Are you facing similar challenges in your wire rod production line? We invite you to contact us for a personalized demonstration of our automatic wire coil compacting and strapping line. Our team of experts is ready to show you how this innovative solution can be tailored to your specific needs, potentially revolutionizing your production process.

Frequently Asked Questions

- Q: How long does it take to install and integrate the automatic wire coil compacting and strapping line?

A: Installation and integration typically take 3-5 days, depending on the complexity of your existing setup. - Q: Can the machine handle different wire rod materials and dimensions?

A: Yes, our system is designed to be flexible and can be adjusted to accommodate various wire rod materials and dimensions within the specified range. - Q: What kind of maintenance does the automatic line require?

A: The system requires minimal maintenance, with routine checks and lubrication recommended on a monthly basis. Our team provides comprehensive training and ongoing support to ensure optimal performance.