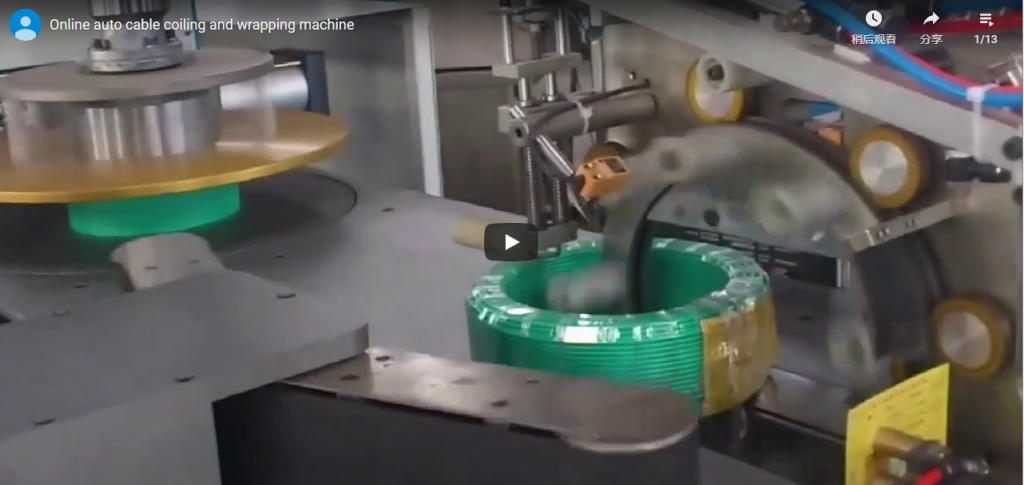

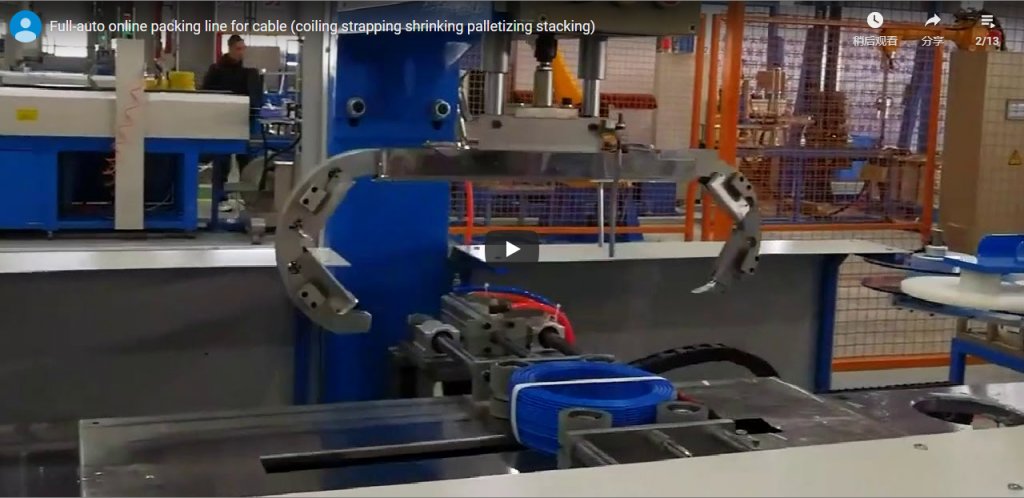

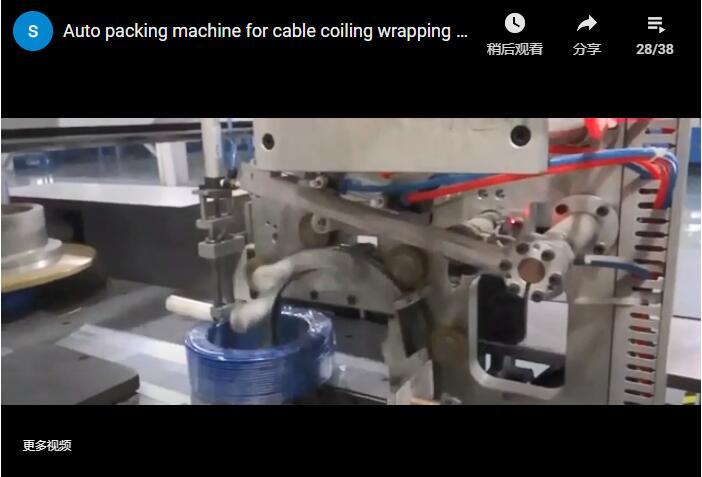

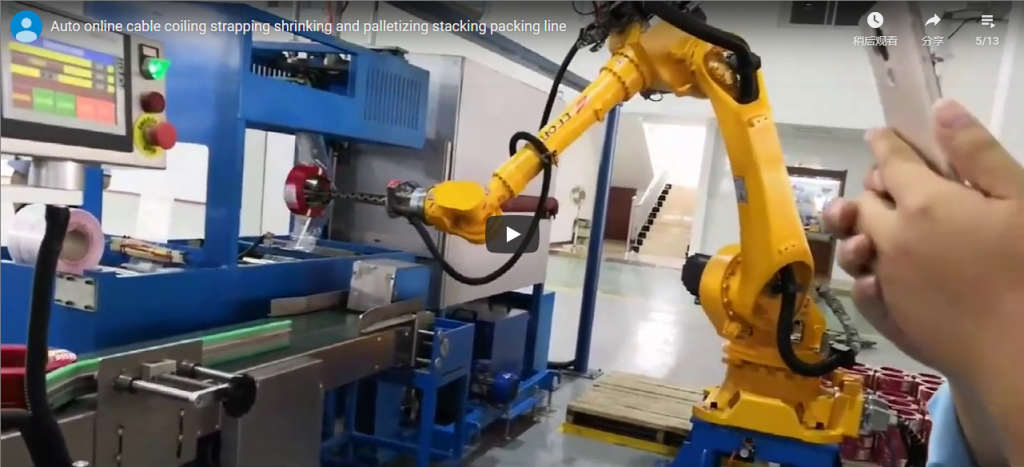

Coil stacking palletizing equipment

The stacking for coil palletazing equipment can be suitable for cable coils, copper coils, hose coil and so on. Auto arranging coils layers and layers on pallet. www.fhopepack.com

Coil stacking palletizing equipment Read More »