Introduction

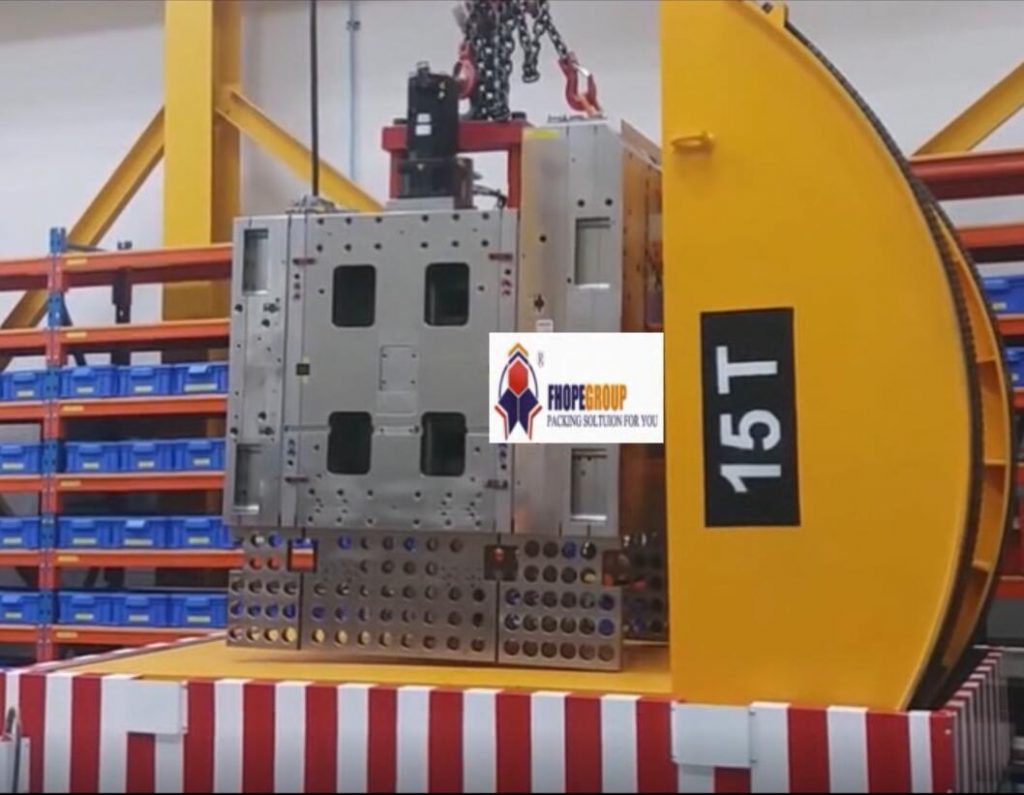

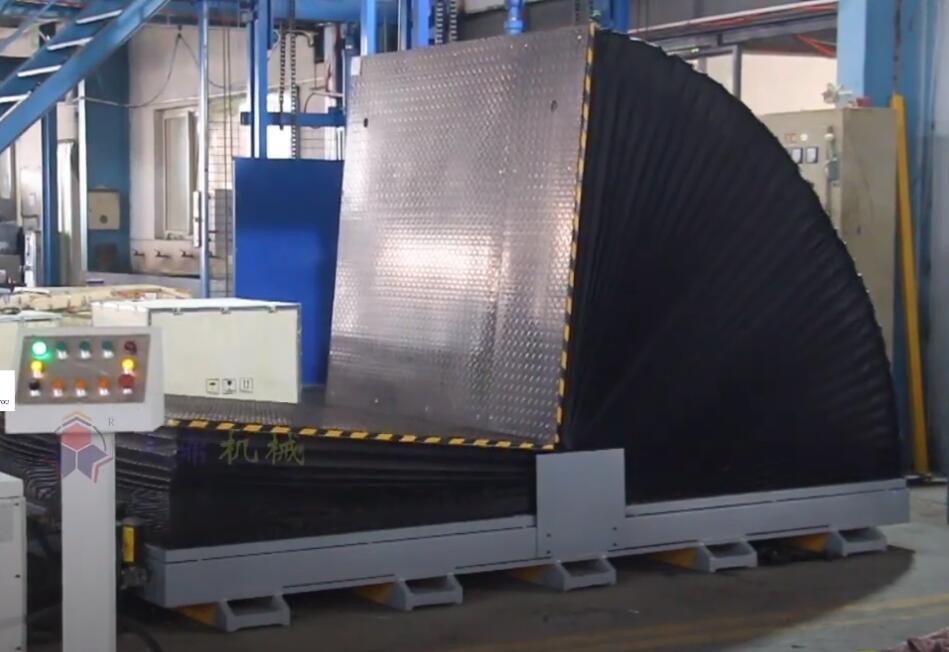

Welcome to a game-changing innovation in pallet handling technology. Our C shape pallet inverter offers a groundbreaking solution for efficient pallet rotation and replacement. This video showcases how our mechanical motor-driven inverter with gear box and pit foundation can transform your warehouse operations, specifically designed for 180-degree pallet turning and broken pallet changing.

Problem-Challenge

At a bustling logistics center in Delhi, India, warehouse managers faced a critical challenge. With no forklifts allowed, limited to hand tools for pallet shifting, and restrictions on high operations, the team struggled with inefficient manual pallet changing processes. Picture a warehouse buzzing with activity, yet bottlenecked by the slow, labor-intensive task of manually rotating and replacing damaged pallets. This not only hampered productivity but also posed potential safety risks to workers.

Customization for Solution

Our C shape pallet inverter is tailored to meet diverse warehouse needs. With a speed of 20-30 pallets per hour, it’s designed to handle pallets sized L1200 x W1200 x H1000-1600mm, weighing up to 1.5 tons. The system’s versatility shines through its dual control options – a panel and remote pad – allowing for seamless operation in various warehouse layouts. This customization ensures that whether you’re dealing with standard or oversized pallets, our solution adapts to your specific requirements.

Key Features and Benefits

The C shape pallet inverter stands out with its innovative design and functionality:

- Ground-Level Operation: Eliminates the need for high-risk elevated work, enhancing safety.

- Mechanical Efficiency: Powered by a robust motor and gear box, ensuring consistent performance.

- Pit Foundation: Provides stability and seamless integration into your warehouse floor.

- Rapid Rotation: Achieves a full 180-degree turn, perfect for quick pallet replacement.

- High Capacity: Handles weights up to 1.5 tons, suitable for most industrial applications.

- User-Friendly Controls: Easy-to-use panel and remote pad for flexible operation.

These features directly address the challenges of manual pallet handling, offering a safe, efficient, and cost-effective solution. By minimizing manual labor and maximizing throughput, our inverter not only boosts productivity but also significantly reduces the risk of workplace injuries.

Contact Us Now

Ready to transform your pallet handling process? We invite you to schedule a personalized consultation with our experts. During this session, we’ll analyze your specific needs and demonstrate how our C shape pallet inverter can be tailored to your warehouse environment. Don’t let inefficient pallet handling hold your operations back any longer. Contact us today to set up your consultation and take the first step towards optimized warehouse efficiency.

FAQs

- How does the C shape pallet inverter improve warehouse safety?

The inverter eliminates the need for manual lifting and high-reach operations, significantly reducing the risk of workplace injuries associated with traditional pallet handling methods. - Can the C shape pallet inverter be integrated into existing warehouse systems?

Yes, its pit foundation design allows for seamless integration into your warehouse floor, and its versatile control options make it compatible with various warehouse layouts and operational flows. - What maintenance is required for the C shape pallet inverter?

The system is designed for low maintenance, requiring only routine checks of the mechanical components and occasional lubrication of moving parts. Our team provides comprehensive guidance on maintenance schedules to ensure long-term reliability and performance.