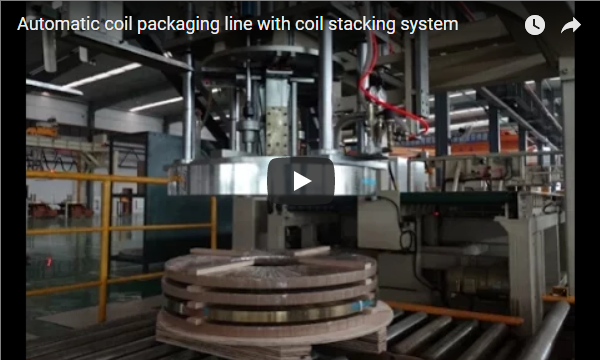

It is an Automating Coil Packaging line with strapping machines for cold rolled steel coil handing and packing.

An automated coil packaging line with strapping machines is engineered to handle the packaging and strapping of coiled materials such as steel, wire, cable, and other rolled products. This system typically integrates uncoiling, straightening, feeding, and strapping modules to create a highly efficient end-to-end solution. The key structural elements often include robust frame construction, precision mechanical alignment, and advanced sensors to ensure consistent positioning of coils for strapping. This line is further enhanced by automated strapping heads that efficiently apply straps around the coils, ensuring they are secure for transit or storage.

The noted parameters below do not 100% match the equipment in the video. For exact specifications, please contact us.

- Type: Coil Packaging Line

- Strapping Material Compatibility: Steel, polyester band

- Coil Diameter: Min 300mm; Max 1600mm

- Strapping Speed: Up to 15 straps per minute

- Control System: Programmable Logic Controller (PLC) with HMI touch screen

- Power Requirements: 440V, 60Hz, three-phase

- Number of Strapping Heads: 2-4, adjustable based on application

- Machine Weight: Approximately 5000kg

- Strap Width: 12mm to 32mm

- Strap Tension: Adjustable, up to 7000 N

- Safety Measures: Fully enclosed with automatic shutdown sensors

- Energy Efficiency: Equipped with a power saving mode

- Durability: Designed for heavy-duty industrial use and high reliability

Applications of the Automated Coil Packaging Line with Strapping Machines:

- Steel Industry: Securing Heavy Coils for Safe Distribution

In the steel industry, handling and distribution of large and heavy coils can pose significant challenges. The automated coil packaging line ensures that these coils are tightly and securely strapped, reducing the risk of uncoiling during transit. The precise and robust strapping mitigates potential damages and accidents, leading to safer transportation and decreased liability for steel manufacturers and distributors. - Electrical Cable Manufacturing: Streamlined Production Efficiency

For electrical cable manufacturers, maintaining continuous and efficient production lines is crucial. The automated strapping in the coil packaging line allows for quick, secure packaging of delicate cables without risking damage. Improved handling and strapping speed increase throughput and reduce downtime, enhancing overall productivity and ensuring timely order fulfillment. - Recycling Facilities: Organization and Storage of Recycled Materials

Recycling facilities dealing with large volumes of scrap materials including coiled wires or cables benefit greatly from automated coil packaging lines. These systems help organize and strap different materials swiftly, making storage more efficient and safer. The automation reduces labor costs and improves sorting and retrieval processes, which is essential for maintaining profitability in the recycling business.

info@fhopepack.com