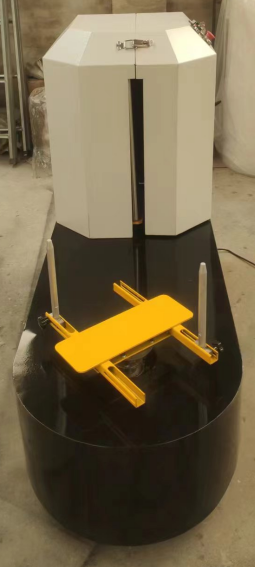

An automatic turntable pallet wrapping machine line is designed to efficiently wrap palletized goods for secure shipment and storage. This type of system generally consists of a rotating turntable where the pallet is placed, and a film dispenser that moves vertically to apply stretch film around the loaded pallet. The operation is fully automated, enhancing wrapping consistency and speed while minimizing labor costs and material usage. These machines often come with adjustable settings to handle different pallet sizes and types of wrap, ensuring optimal security and product protection irrespective of load shape and content variability.

The parameters below do not 100% match the equipment in the video. For exact specifications, please contact us.

- Type: Automatic Turntable

- Wrapping Speed: Up to 45 pallets per hour

- Max Load Size: Length: 1200mm; Width: 1200mm; Height: 2400mm

- Film Carriage Speed: Adjustable, up to 5m/min

- Turntable Speed: 3-12 rpm, adjustable

- Film Type Compatibility: Stretch film, pre-stretched film

- Power Requirements: 230V, 50Hz, single phase

- Control System: PLC with user-friendly interface

- Machine Dimensions: Diameter: 2000mm; Height: 2500mm

- Load Capacity: Up to 2000kg

- Safety Features: Emergency shut-off, surround guarding

- Customization: Available for turntable diameter, wrap height

- Efficiency: Advanced pre-stretch system (up to 250%)

Applications of the Automatic Turntable Pallet Wrapping Machine Line:

- Warehouse Logistics: Enhancing Load Security and Handling Efficiency

In logistics operations, securing cargo is pivotal to maintaining goods integrity during transit and storage. The automatic wrapping machine ensures that all sides of the pallet are uniformly covered with film, significantly increasing load stability. This robust wrapping reduces the risk of product shifting or damage, leading to fewer incidents of returned or rejected shipments and enhanced operational throughput. - Food and Beverage Distribution: Maintaining Cleanliness and Product Safety

For the food and beverage industry, cleanliness and safety are top priorities. The pallet wrapping machine helps encase products in a protective layer that guards against contamination and moisture. This level of protection is crucial in preventing spoilage and ensuring that products meet health and safety standards upon delivery, vital for consumer safety and regulatory compliance. - Manufacturing Sector: Streamlined Packaging Process

In manufacturing, the transition of goods from production to distribution is critical. The pallet wrapping machine line integrates seamlessly into production flows, turning a multi-step process into a streamlined operation. This integration reduces labor costs and time delays, providing a smoother transition from manufacturing to warehousing or distribution, thus enhancing overall productivity and reducing operational bottlenecks.

info@fhopepack.com