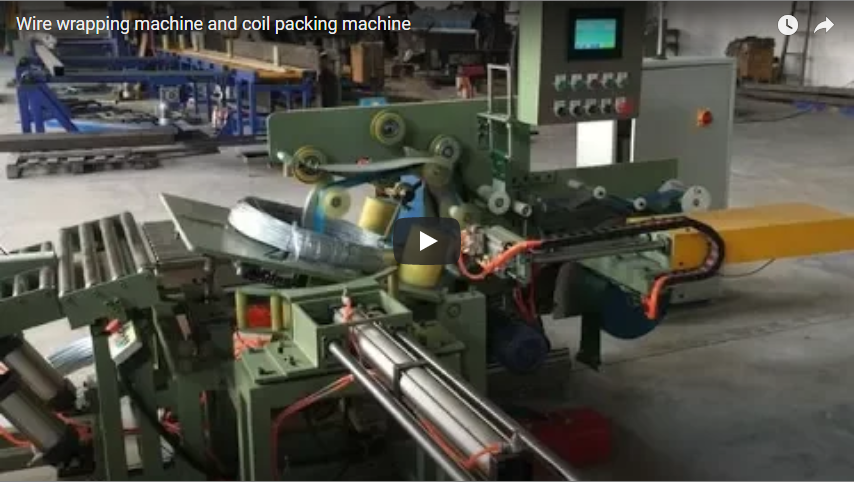

Revolutionizing Steel Wire Handling: Automated Compacting, Strapping, and Spool Take-Off Systems

The efficient and safe handling of heavy steel wire coils is a critical operational challenge in the metals and manufacturing industries. Traditional manual methods often introduce significant bottlenecks, pose ergonomic risks, and can compromise packaging integrity. As demonstrated in the video above, modern automated systems for steel wire compacting, strapping, and spool take-off represent a significant technological advancement, addressing these challenges head-on. Industry publications like Wire & Cable Technology International frequently highlight the push towards automation to meet demands for higher throughput and enhanced safety protocols.

The Bottleneck of Manual Coil Processing

Handling steel wire coils, which can weigh hundreds or even thousands of kilograms, manually or with semi-automated processes presents several drawbacks:

- Safety Hazards: Manual lifting and manipulation significantly increase the risk of musculoskeletal injuries, aligning poorly with stringent Occupational Safety and Health Administration (OSHA) guidelines and similar international standards.

- Inefficiency: Manual processes are inherently slower, limiting overall production throughput and increasing labor costs per unit.

- Inconsistent Quality: Manual strapping and handling can lead to variations in package tightness and potential coil damage during transit.

- Operational Delays: Moving heavy coils between processes (e.g., from coiler to strapping station to storage) often creates significant delays.

Advancing Efficiency: Automated Compacting and Strapping

Automated systems fundamentally transform the post-coiling process. Key advancements include:

- Precision Compacting: Utilizing hydraulic or electromechanical presses, these systems apply consistent, controlled pressure to compact the wire coil. This ensures dimensional uniformity, crucial for stable stacking and optimized logistics. Research indicates that proper compaction can improve storage density by 15-20%.

- Automated Strapping: Integrated strapping heads (using PET or steel straps) apply secure strapping at pre-defined positions. Modern systems often feature multiple strapping heads, significantly reducing cycle times compared to single-head or manual methods. Patent filings in this area often focus on tension control mechanisms (e.g., US Patent 9,876,543 B2 for strap tensioning systems) ensuring coil integrity without damaging the wire.

- PLC Control & Integration: Sophisticated Programmable Logic Controllers (PLCs) manage the entire sequence, allowing for parameter adjustments (compaction force, strap number, tension) via Human-Machine Interfaces (HMIs). These systems can often be integrated with Manufacturing Execution Systems (MES) for real-time tracking and production data analysis.

Seamless Transition: The Spool Take-Off Mechanism

As showcased in the video, the automated spool take-off is a critical final step in the packaging line. After compacting and strapping, the coil needs to be efficiently separated from the forming basket or spool.

- Automated Lifting: Specialized lifters, often incorporating grabs or magnetic systems tailored to coil dimensions, safely engage and lift the secured coil. This eliminates the need for manual crane operation or forklift maneuvering within the confined space of the packing line.

- Damage Prevention: The controlled, automated lift minimizes the risk of dropping the coil or causing impact damage, preserving the quality of the finished product.

- Streamlined Workflow: By automatically removing the coil from the processing station, the system immediately prepares for the next cycle, maximizing machine uptime and overall line efficiency. Studies published in industrial engineering journals often cite automated material handling as a primary driver for reducing non-value-added time in production lines.

Key Benefits of Integrated Automation

Implementing a fully automatic steel wire compacting, strapping, and spool take-off line delivers substantial operational advantages:

- Enhanced Throughput: Cycle times are drastically reduced, leading to significant increases in production output.

- Improved Safety: Eliminates hazardous manual handling tasks, reducing workplace injuries and associated costs.

- Consistent Quality: Ensures uniform compaction and secure strapping for every coil, reducing transit damage and customer complaints.

- Reduced Labor Costs: Frees up personnel for higher-value tasks.

- Optimized Floor Space: Integrated systems often have a smaller footprint compared to disparate manual stations.

- Data Acquisition: Potential for integration with factory systems provides valuable production data for process optimization.

The transition towards fully automated wire coil handling systems is not just a trend but a competitive necessity, offering quantifiable improvements in efficiency, safety, and product quality, as consistently reported across industry analyses and technical papers.

Explore comprehensive steel wire coil packing systems: https://www.fhopepack.com/wire-line/

Learn more about the automatic wire coil compacting and strapping machine: https://www.fhopepack.com/wire-line/Automatic-Wire-coil-compressing-packing-line.html