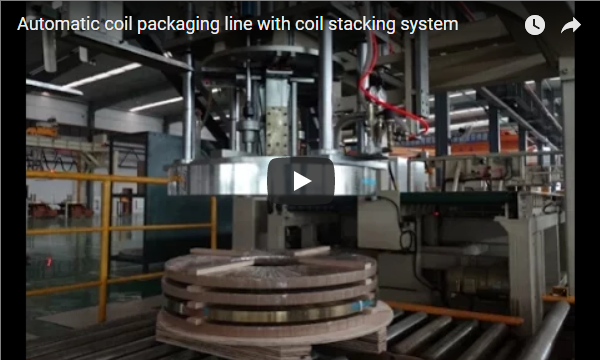

Video for Automatic steel wire coil rewinding and compacting line

How Automated Packaging Lines Overcome Challenges in Steel Wire Coil Production

Steel wire coils are critical components in various industries, including construction, manufacturing, and automotive. However, the production and packaging of steel wire coils come with unique challenges due to their weight, size, and vulnerability to damage. Traditional manual or semi-automated processes often fall short when it comes to efficiency, safety, and consistency, leading to higher costs and lower productivity. Enter automated packaging lines, which are transforming the way steel wire coils are handled, packaged, and transported.

In this comprehensive guide, we’ll delve into how automated packaging lines address the challenges of steel wire coil production. By exploring their benefits, features, and future potential, you’ll see why automation is the key to staying competitive in today’s industrial landscape.

1. Understanding the Challenges in Steel Wire Coil Production

Steel wire coil production is a complex process that involves various stages, from wire drawing and annealing to coiling and packaging. Each stage presents unique challenges that require precision and efficiency. Some of the most common issues include:

- Heavy Weight and Bulkiness: Steel wire coils are heavy, with some weighing several tons. Handling them manually is time-consuming and poses risks to workers.

- Vulnerability to Damage: Despite their robust appearance, steel wire coils can suffer from surface defects like scratches, rust, or dents, which can compromise their quality and usability.

- Inconsistent Packaging: Manual or semi-automated methods often result in uneven wrapping, strapping, or compacting, increasing the risk of damage during transportation.

- Labor-Intensive Processes: Traditional methods rely heavily on manual labor, leading to slower production cycles and higher operational costs.

- Safety Risks: The manual handling of heavy coils exposes workers to potential injuries, such as back strain, crushing accidents, or mishandling-related hazards.

These challenges demand a solution that prioritizes efficiency, consistency, and safety—making automated packaging lines an essential investment for steel wire coil manufacturers.

2. What Are Automated Packaging Lines?

Automated packaging lines are highly specialized systems designed to streamline the handling, packaging, and transportation of steel wire coils. These systems integrate advanced machinery and technology to automate repetitive tasks while improving precision and output. Typical components of an automated steel wire coil packaging line include:

- Automatic Wire Pay-Off Machines: Ensure wire is fed seamlessly for coiling or rewinding.

- Wire Rewinding Machines: Precisely rewind wire onto spools or coils, ensuring consistency.

- Wire Strapping Machines: Securely strap the wire coils to prevent movement during transit.

- Wire Compacting Machines: Compress coils into compact shapes, reducing storage and transportation space.

- Down-Enders: Rotate coils into the desired position for further handling or storage.

- Unloading Systems: Automatically transfer packaged coils to storage areas or transport vehicles.

These systems are designed to handle the unique demands of steel wire coil production, offering a wide range of benefits that traditional methods cannot match.

3. Boosting Efficiency with Automation

One of the most significant advantages of automated packaging lines is their ability to enhance operational efficiency. Unlike manual processes, which are prone to delays and bottlenecks, automated systems operate continuously and at high speeds.

Key Efficiency Benefits:

- Faster Packaging Cycles: Automated systems can handle multiple coils simultaneously, drastically reducing packaging time.

- Seamless Integration: These lines can be integrated with upstream production processes, creating a smooth workflow from wire drawing to packaging.

- Reduced Downtime: Automation minimizes human error and machine stoppages, ensuring uninterrupted production.

By optimizing efficiency, manufacturers can increase their output and meet growing demand without compromising quality.

4. Improving Safety in the Workplace

Safety is a critical concern in steel wire coil production due to the weight and size of the coils. Traditional manual handling methods expose workers to significant risks, including accidents and injuries. Automated packaging lines address these concerns by reducing the need for manual intervention.

How Automation Enhances Safety:

- Minimized Human Interaction: Workers no longer need to lift, move, or strap heavy coils manually, significantly reducing the risk of injury.

- Advanced Safety Features: Modern systems are equipped with sensors, emergency stop mechanisms, and automated error detection to prevent accidents.

- Ergonomic Design: Automated machinery is designed to handle heavy loads, eliminating the physical strain on workers.

By improving workplace safety, companies can protect their employees and reduce costs associated with workplace injuries.

5. Ensuring Consistent Packaging Quality

Consistency is crucial when it comes to packaging steel wire coils. Uneven wrapping or strapping can lead to product damage, customer complaints, and financial losses. Automated packaging lines ensure that every coil is packaged to the same high standard.

Features That Guarantee Consistency:

- Precise Wrapping: Machines apply uniform tension and coverage when wrapping coils, providing superior protection against dust, moisture, and scratches.

- Reliable Strapping: Automated strapping ensures that coils are securely bound, preventing movement during transport.

- Customizable Settings: Systems can be adjusted to accommodate different coil sizes, weights, and packaging requirements, ensuring a tailored approach for every product.

The result is high-quality packaging that minimizes damage and enhances customer satisfaction.

6. Cost Efficiency of Automated Packaging Lines

Investing in automation may seem like a significant upfront expense, but the long-term cost savings are undeniable. Automated packaging lines reduce operational costs by:

- Lowering Labor Expenses: Automation reduces reliance on manual labor, cutting down on wages and associated costs.

- Minimizing Material Waste: Precision wrapping and strapping minimize the use of packaging materials, saving money and reducing environmental impact.

- Increasing Productivity: Faster cycle times and reduced downtime enable manufacturers to produce more in less time, boosting revenue.

By delivering a strong return on investment (ROI), automated packaging lines are a cost-effective solution for steel wire coil manufacturers.

7. Protecting Steel Wire Coils During Transit

Transporting steel wire coils is a delicate process, as improper handling can lead to surface damage or deformation. Automated packaging lines are designed to ensure the safe transportation of coils by:

- Applying Protective Layers: Stretch films and other materials shield the coils from external elements like moisture, dirt, and scratches.

- Secure Strapping: High-tension strapping keeps the coils tightly bound, preventing movement during transit.

- Compact Stacking: Compacting machines reduce the size of the coils, making them easier to store and transport.

By protecting the integrity of the product, manufacturers can reduce losses and maintain customer trust.

8. Scalability for Growing Operations

As businesses expand, their production processes must adapt to meet increased demand. Automated packaging lines are highly scalable, making them ideal for growing operations.

Scalability Features:

- Modular Design: Additional components can be added to the system as production needs grow.

- Customizable Configurations: Machines can handle a variety of coil sizes and packaging specifications, providing flexibility for diverse product lines.

- High Throughput: Automated systems can process large volumes of coils without compromising quality or speed.

This scalability ensures that manufacturers remain competitive in a rapidly evolving market.

9. Sustainability and Environmental Impact

Sustainability is becoming an increasingly important consideration for manufacturers. Automated packaging lines contribute to greener operations by:

- Reducing Material Waste: Precision in wrapping and strapping minimizes the use of packaging materials, reducing waste.

- Energy Efficiency: Modern systems are designed to consume less energy while maintaining high performance.

- Recyclable Materials: Many automated systems use eco-friendly packaging materials that can be recycled, reducing environmental impact.

By adopting sustainable practices, manufacturers can align with industry standards and appeal to environmentally conscious customers.

10. The Future of Automated Packaging Lines

The future of steel wire coil production lies in advanced technologies such as Artificial Intelligence (AI), the Internet of Things (IoT), and robotics. These innovations are expected to further enhance the efficiency and precision of automated packaging lines.

Emerging Trends:

- AI-Powered Systems: AI can analyze data to optimize workflows, predict maintenance needs, and improve decision-making.

- IoT Integration: IoT-enabled machines can communicate with each other, creating a fully connected and intelligent production line.

- Robotic Automation: Robotic arms and automated guided vehicles (AGVs) will further streamline the handling and packaging of steel wire coils.

By staying ahead of these trends, manufacturers can unlock new levels of productivity and profitability.

Conclusion

Automated packaging lines are revolutionizing steel wire coil production by addressing critical challenges such as inefficiency, safety risks, and inconsistent packaging quality. These systems streamline operations, reduce costs, and ensure the safe handling of coils, making them an indispensable asset for manufacturers.

As technology continues to evolve, the integration of AI, IoT, and robotics will further enhance the capabilities of automated packaging lines. By investing in these advanced solutions, businesses can stay competitive, meet growing demand, and achieve long-term success. The future of steel wire coil production is automated—and the time to embrace it is now.