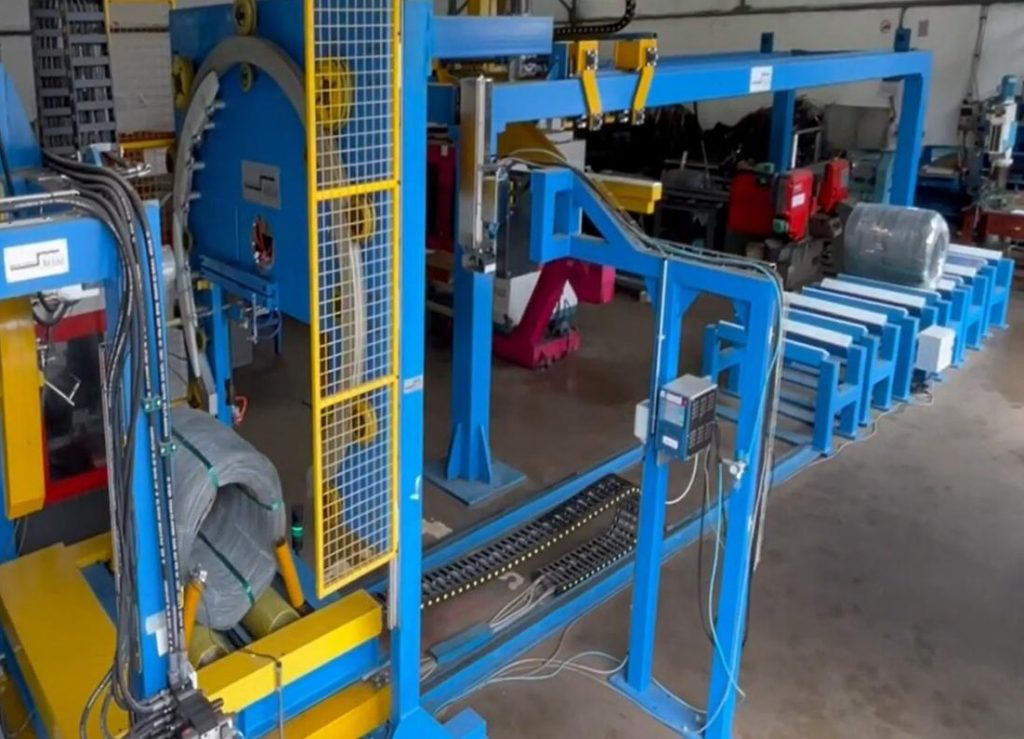

The video showcasing the steel wire packing process highlights a highly automated system designed to streamline operations in steel wire coil production facilities. This advanced process begins with the automatic coil loading onto trolleys, a crucial initial step that ensures efficiency and minimizes the need for manual intervention. The process continues with automatic wrapping by eye through technology, which provides a precise and secure method of packaging the coils .

Following the wrapping stage, the system features automatic trolley loading, allowing for seamless transition of coils onto transport trolleys. This step is complemented by an automatic picking up and storage system, which efficiently organizes and stores the packed coils, optimizing space and reducing handling time. Remarkably, this entire process is designed to be managed by just one person, showcasing the system’s efficiency and effectiveness in reducing manpower requirements .

Key features of this packing line include an automatic film cutter and an automatic labeling machine, both of which enhance the packaging process by ensuring consistency and accuracy. The control system is powered by PLC technology, offering precise control and monitoring of the entire operation .

The use of a servo stacking system for loading and unloading further enhances the process, providing smooth and efficient handling of the coils. This sophisticated system is part of a broader range of automatic packing lines tailored for steel wire coils, each designed to meet specific production needs while maintaining high standards of safety and efficiency .

In summary, the automated steel wire packing line represents a significant advancement in packaging technology, enabling facilities to achieve high productivity with minimal human intervention, thereby reducing labor costs and increasing overall efficiency .