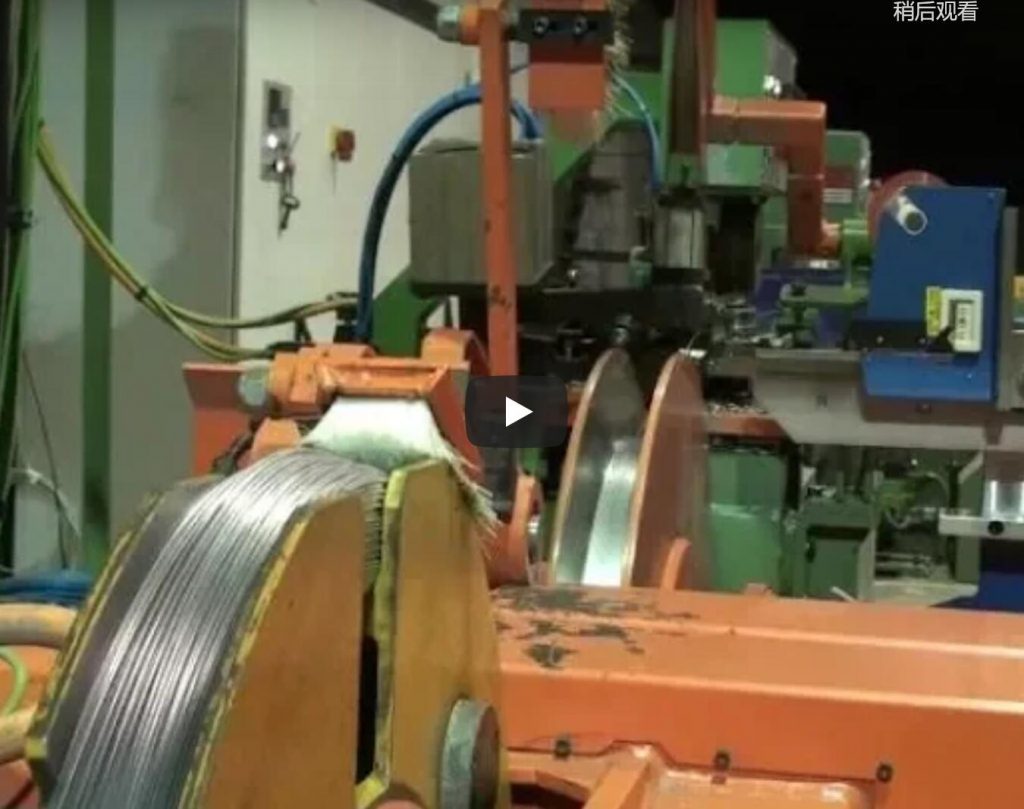

Automatic pipe coiling and strapping machine

This is a video for Automatic pipe coiling and strapping machine.

How Automatic Pipe Coiling and Strapping Machines Can Boost Production Efficiency

In the industrial world, efficiency is the key to success. Companies constantly look for ways to streamline operations and maximize output. One such innovation that has revolutionized production is the automatic pipe coiling and strapping machine. This article delves into how these machines can significantly enhance production efficiency, offering a competitive edge in the market.

Understanding Automatic Pipe Coiling and Strapping Machines

Automatic pipe coiling and strapping machines are specialized equipment designed to automate the process of coiling pipes and securing them with straps. These machines are widely used in industries dealing with plastic pipes, hoses, and cables. By automating these tasks, businesses can save time, reduce labor costs, and minimize the risk of human error.

Key Features of Automatic Pipe Coiling Machines

- Precision and Consistency: One of the primary benefits of these machines is their ability to deliver precise and consistent coils. Manual coiling can lead to variations that affect product quality and storage efficiency.

- Speed Adjustment: Many modern machines come with adjustable speed settings, allowing operators to tailor the coiling speed to the material and diameter of the pipe, enhancing flexibility and control.

- Automated Cut and Strap: These machines can automatically cut the pipe to the desired length and apply straps, reducing the need for manual intervention and speeding up the process.

Advantages of Using Automatic Pipe Coiling Machines

The use of automatic pipe coiling machines has transformed how industries handle the coiling and strapping of pipes. In sectors such as construction, manufacturing, and plumbing, where time and efficiency are critical, automation plays a key role. While manual processes were once the norm, the shift towards automatic systems has brought about numerous benefits that go beyond just speed. This article will dive deeper into the core advantages of using automatic pipe coiling machines, focusing on production speed, labor cost reduction, enhanced safety, and improved product quality.

1. Increased Production Speed

One of the most significant advantages of automatic pipe coiling machines is the increase in production speed. In today’s fast-paced industrial environment, meeting tight deadlines is crucial to staying competitive. By automating the coiling and strapping processes, companies can significantly boost their throughput, meaning more products are ready for distribution in less time.

Unlike manual operations, where workers might struggle to maintain consistent speeds, automatic machines operate at a continuous and reliable pace. Automatic coiling machines are programmed to perform repetitive tasks with precision and speed, ensuring that the process is smooth and efficient. This increase in output allows companies to meet customer demands more effectively, reducing bottlenecks in production lines and speeding up the overall supply chain.

Moreover, with automatic machines, companies can run their operations 24/7 with minimal supervision. This capability is particularly valuable in industries that require round-the-clock production to keep up with demand. Continuous operation without human fatigue means higher overall productivity and a faster return on investment.

2. Labor Cost Reduction

The shift to automatic coiling machines not only increases production speed but also brings substantial savings in labor costs. Manual coiling and strapping require a significant workforce to operate efficiently, and labor costs are often one of the largest expenses in manufacturing. By automating the process, companies can reduce their reliance on manual labor, which translates into considerable cost savings over time.

With fewer workers needed for the coiling process, labor resources can be reassigned to more critical tasks within the facility, optimizing workforce utilization. This reallocation not only improves overall productivity but also allows businesses to focus on other areas of operation that may require specialized skills.

Additionally, the reduction in labor costs is not limited to wages alone. Manual tasks are often associated with higher turnover rates, as repetitive or physically demanding jobs can lead to burnout or dissatisfaction among employees. By automating these repetitive tasks, businesses can reduce turnover, lower recruitment costs, and improve employee satisfaction by focusing human resources on more engaging and value-added work.

3. Enhanced Safety

Workplace safety is another crucial area where automatic pipe coiling machines excel. Manual coiling and strapping processes involve repetitive motions and the handling of heavy materials, both of which pose significant safety risks. Workers are often required to bend, lift, and coil pipes repeatedly, which can lead to musculoskeletal injuries over time. Additionally, the physical demands of these tasks increase the likelihood of accidents, especially in fast-paced environments.

Automatic machines eliminate these risks by reducing the need for manual intervention. Instead of having workers manually handle the coiling and strapping of heavy pipes, machines take over, ensuring a safer working environment. This reduction in manual handling minimizes the risk of injuries related to lifting or repetitive strain, which in turn reduces workers’ compensation claims and lowers associated costs.

In many cases, automatic machines come equipped with built-in safety features like emergency stop buttons, sensors, and protective barriers that prevent accidents during operation. These features further enhance workplace safety, providing operators with peace of mind as they work alongside the equipment.

4. Improved Product Quality

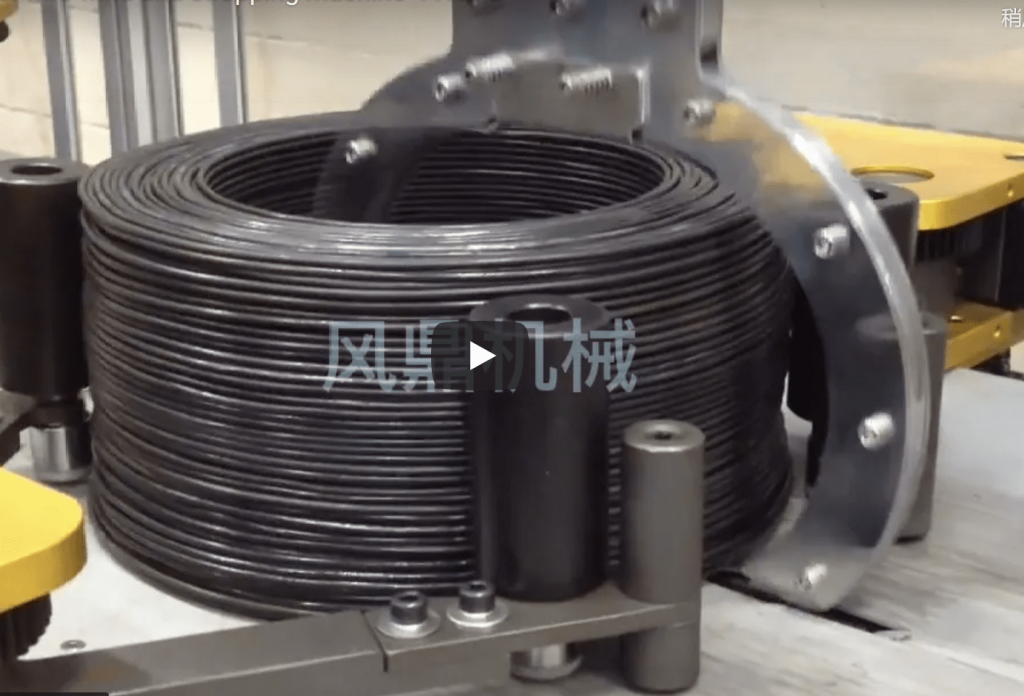

Quality control is a major concern in any manufacturing or processing industry, and the precision of automatic pipe coiling machines ensures that each product meets consistent standards. Unlike manual coiling, which can result in variability in the tightness of the coils and strapping, automatic machines provide uniformity with every cycle.

Consistent coiling and strapping are essential for maintaining the integrity of the pipes during transportation and storage. Pipes that are improperly coiled or strapped can shift or loosen, leading to damage, defects, or even safety hazards during shipment. With automatic machines, every pipe is coiled and strapped with perfect precision, ensuring that they remain securely packed and protected throughout their journey.

In addition to ensuring physical protection, improved coiling precision can also enhance aesthetic quality, which is important for industries where appearance plays a role in product appeal. Pipes that are neatly coiled and uniformly strapped give an impression of quality and professionalism, helping companies maintain a good reputation with their customers.

Moreover, automatic machines can be programmed to handle a variety of pipe sizes and materials, offering flexibility without compromising on quality. This versatility means that manufacturers can switch between different products without sacrificing efficiency or precision, ensuring that each batch meets the highest quality standards.

Technological Innovations in Pipe Coiling Machines

The industry has seen several technological advancements aimed at improving machine performance and efficiency:

1. Integration with IoT

Many machines now come equipped with IoT capabilities, allowing operators to monitor performance in real-time. This integration helps in predictive maintenance, reducing downtime and prolonging machine life.

2. Energy Efficiency

Modern machines are designed to be more energy-efficient, reducing the overall carbon footprint of manufacturing operations. This not only helps in cost savings but also aligns with sustainable business practices.

3. User-Friendly Interfaces

Today’s machines feature intuitive interfaces that make them easy to operate. With touchscreens and automated controls, operators can quickly learn to manage the machines, reducing training time and errors.

Considerations for Implementing Automatic Machines

Before investing in an automatic pipe coiling and strapping machine, it’s important to consider several factors:

1. Initial Cost vs. Long-Term Savings

While the initial investment can be substantial, the long-term savings in labor and increased production efficiency often justify the cost. It’s essential to perform a cost-benefit analysis to ensure the investment aligns with business goals.

2. Compatibility with Existing Systems

Ensure that the new machine is compatible with your existing production line. This includes checking the machine’s capacity, speed, and material handling capabilities.

3. Maintenance and Support

Look for machines that come with robust maintenance and support options. Regular servicing is crucial to maintain optimal performance and prevent unexpected breakdowns.

Case Studies: Success Stories

Company A: Streamlining Operations

Company A, a leading manufacturer of PVC pipes, implemented automatic coiling and strapping machines to address bottlenecks in their production line. The result was a 30% increase in production capacity and a 20% reduction in labor costs. The company also reported fewer defects, leading to higher customer satisfaction.

Company B: Enhancing Quality Control

Company B, specializing in flexible hoses, faced challenges with inconsistent product quality due to manual coiling. After adopting automated machines, they achieved uniform coiling, which improved their product’s reliability and durability. This change helped them secure new contracts, boosting their market share.