This is a video for automatic crate and tote dumper.

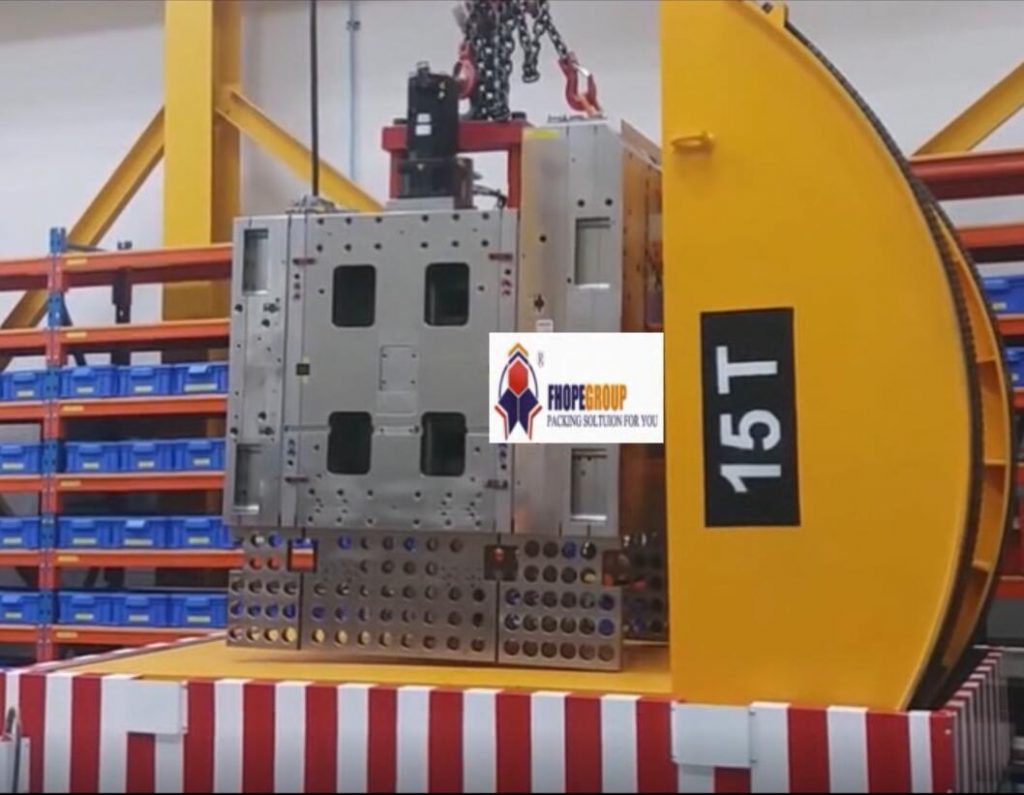

FHOPEPACK specializes in the design and manufacture of advanced dumper automation machines, specifically tailored for handling crates and totes. These machines are equipped with a robust control system that ensures precise operation and a high degree of operator visibility. The design facilitates easy filling and unloading, enhancing workflow efficiency.

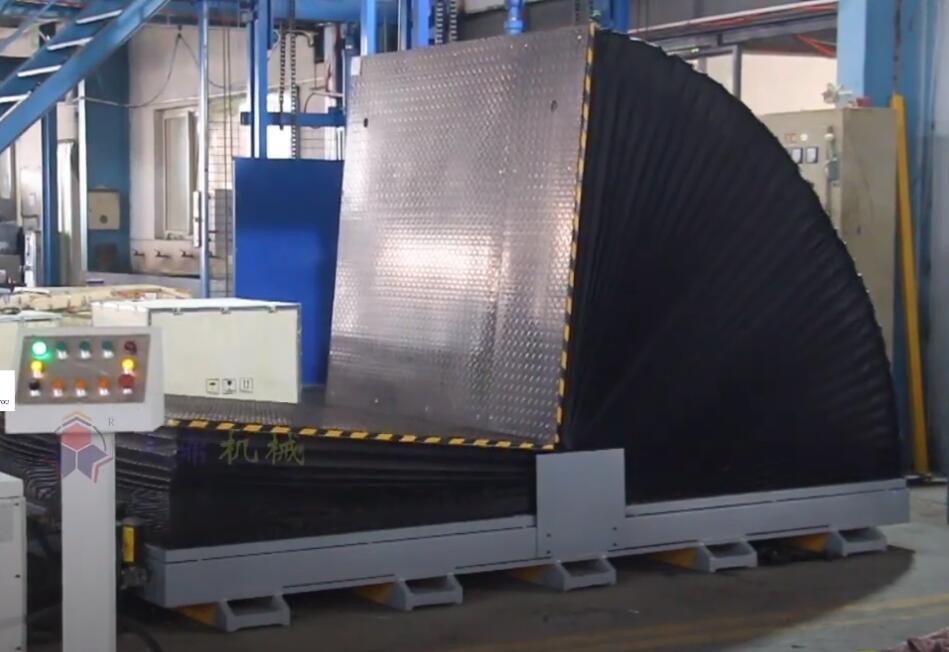

The tote dumper by FHOPEPACK is ideal for recycling centers where it can handle loads up to 2000 kg, lifting scrap metal into trolleys efficiently. The machine's 3-meter lift height and rapid drop speed facilitate quick cycle times, reducing bottlenecks in material handling. Its robust safety features ensure secure operations, crucial in high-volume waste management environments.

In food processing industries, this dumper is essential for managing bulk ingredients. It can accommodate various crate sizes, streamlining the transfer of items like grains and spices into processing units. The system's design minimizes physical strain on workers and speeds up the production line, which is particularly beneficial during peak harvest seasons.

For logistic centers, the automation of crate handling simplifies the loading and unloading of goods, with a capacity to handle significant weight and volume. The machine's adjustable settings allow for handling different crate dimensions, which is vital for operations that deal with a diverse range of products. This adaptability, combined with efficient cycle times, helps in maintaining a smooth flow of goods, thereby optimizing storage and transportation processes.