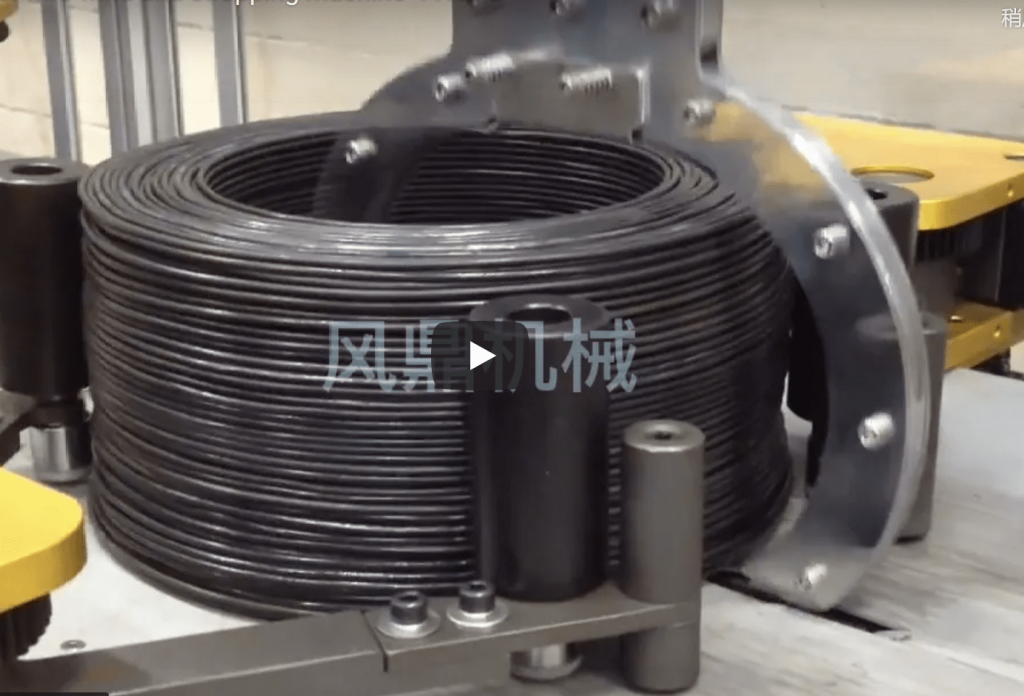

The Automatic Coiler for Hose is specifically developed to handle the winding and coiling of hoses, such as garden hoses, industrial tubing, and other flexible pipes. It is engineered to provide tight, uniform coils without damaging the hose material. This machine typically consists of a feed mechanism, an adjustable coiling head to accommodate hoses of various diameters and lengths, and an automatic cutting feature that facilitates efficient production cycles. The robust design ensures maximum productivity with minimal human intervention, making it an ideal solution in settings that require high volumes of hose coiling with consistent quality.

**The parameters below do not 100% match the equipment in the video. For exact specifications, please contact us.**

– Type: Automatic Hose Coile

– Model: HC-200Pro

– Year of Manufacture: 2023

– Hose Diameter Compatibility: 10mm to 100mm

– Maximum Coil Diameter: 800mm

– Coiling Speed: Up to 50 meters per minute

– Control System: PLC with touchscreen operation

– Power Requirements: 380V, 50Hz, three phase

– Machine Dimensions: Length: 3000mm; Width: 1500mm; Height: 2000mm

– Structural Material: Stainless steel for corrosion resistance

– Coil Binding Options: Nylon ties, metal clamps, or heat seal

– Adjustable Tension Control: Yes

– Safety Features: Integrated safety shields and emergency stop

– Compliance: CE, ISO 9001

– Maintenance Features: Easy access panels for routine maintenance

– Operator Training: Provided on-site at installation

– Warranty: 5-year limited warranty

Application 1: **Increased Production Efficiency in Garden Hose Manufacturing**

The Automatic Coiler for Hose significantly enhances production efficiency in the production of garden hoses. By automating the coiling process, it enables manufacturers to handle up to 50 meters of hose per minute, greatly reducing the time and labor typically required. This high-speed operation ensures hoses are coiled uniformly, making the packaging, storage, and distribution processes more efficient. Additionally, the precise coiling reduces material stress and potential damage, ensuring that the hoses maintain their quality and functionality over time.

Application 2: **Cost Reduction in Industrial Hose Production**

In industrial settings where large volumes of hoses are manufactured, this machine offers substantial cost savings by automating the coiling process. The precision and speed with which it operates eliminate the need for extensive manual labor, thus cutting down workforce costs and enhancing production output. The accurate coiling also minimizes material waste and optimizes the use of storage space, further driving down costs and improving the overall profitability of operations.

Application 3: **Quality Assurance in Flexible Pipe Packaging**

For manufacturers of flexible pipes used in various applications like irrigation, automotive, and medical devices, maintaining product quality during handling and shipping is crucial. The Automatic Coiler for Hose ensures each pipe is coiled with uniform tension and secured properly, which helps in maintaining the integrity of the pipes during transport. This consistent quality assurance is critical in industries where even minor defects can lead to significant operational disruptions, thus ensuring customer satisfaction and compliance with stringent industry standards.

For more details, feel free to contact info@fhopepack.com