Elevating Efficiency in Steel Tile Handling: The Automatic Bundle Stacking Machine

In demanding industrial environments like metal fabrication and construction supply, optimizing material handling processes is critical for productivity, safety, and cost-efficiency. Our Automatic Bundle Stacking Machine for Steel Tiles represents a significant advancement in automating the often labor-intensive task of stacking steel tiles, leveraging sophisticated engineering principles referenced in material handling research and automation patents.

Operational Principles and Design

This automated system is engineered to streamline the stacking process from start to finish. An Automatic Bundle Stacking Machine for Steel Tiles typically incorporates several key subsystems:

- Infeed Conveyor: Transports individual or grouped steel tiles into the stacking zone.

- Alignment Mechanism: Ensures tiles are correctly positioned before lifting, often using sensors and mechanical guides for precision, a common feature highlighted in automated assembly literature.

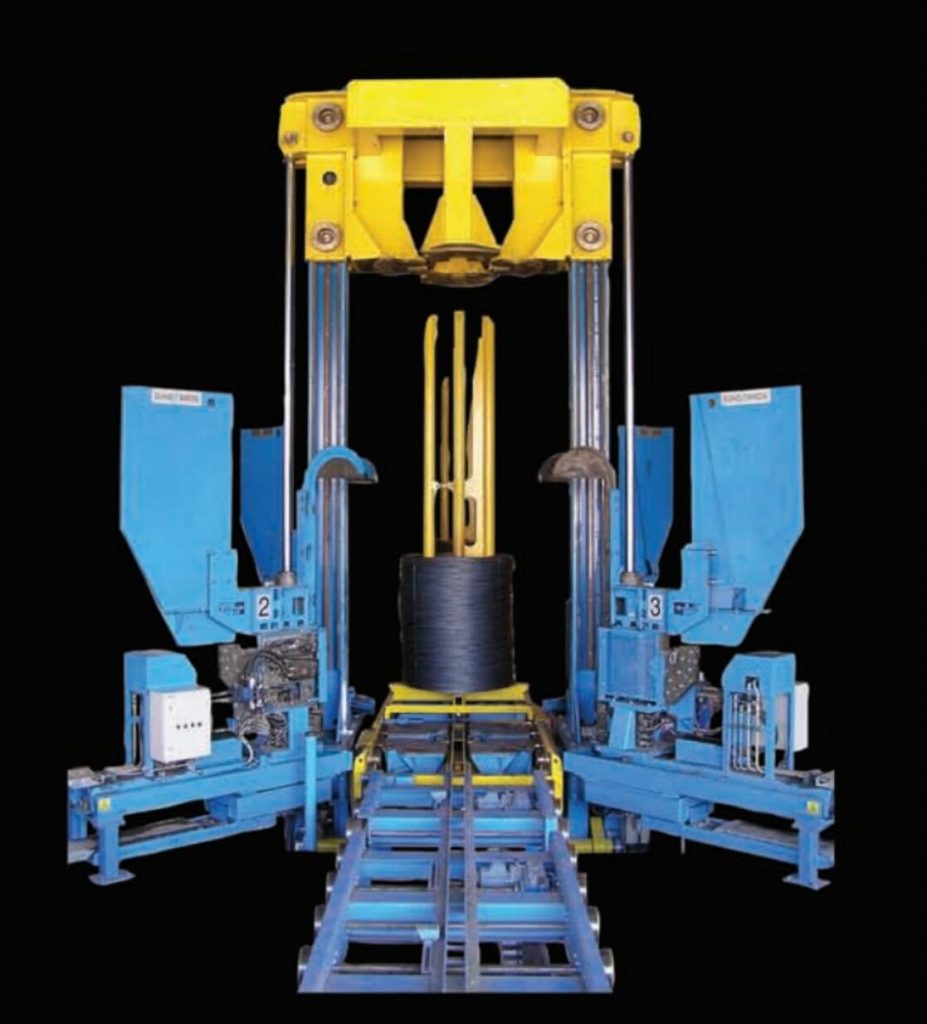

- Lifting System: Utilizes robust technology, frequently magnetic suction grippers (as seen in the video) or vacuum systems depending on tile properties, to securely lift tiles. The design of such end-effectors is a subject of ongoing research for handling diverse metal sheet types efficiently (Source: Journal of Manufacturing Systems articles on robotic gripping).

- Stacking Unit: Carefully places tiles onto a growing bundle, maintaining alignment and stability. Control logic often includes algorithms to optimize stack patterns and ensure density, drawing parallels to optimization techniques discussed in logistics and warehousing research papers.

- Discharge System: Moves the completed stack out of the machine, often onto another conveyor or palletizing station, ready for strapping or shipping.

The entire operation is orchestrated by a Programmable Logic Controller (PLC) integrated with sensors (photoelectric, proximity) and a Human-Machine Interface (HMI), typically a touchscreen. This allows for parameter adjustments, recipe management for different tile sizes, and real-time monitoring, aligning with Industry 4.0 principles of connected manufacturing.

Key Features and Technical Specifications

Please note: The parameters listed below provide a general overview. Specific configurations may vary based on application requirements. Contact us for detailed specifications tailored to your needs.

- Machine Type: Automatic Bundle Stacking Machine for Steel Tiles

- Operation Mode: Fully Automated

- Handling Material: Steel Tiles (various gauges and coatings potentially accommodated)

- Example Tile Size Capacity: Length: up to 1200mm; Width: up to 800mm (Adjustable range available)

- Typical Throughput: Up to 200 tiles per hour (Variable based on tile size and stack configuration)

- Power Requirements: 380V, 50Hz, three-phase (Adaptable to regional standards)

- Approximate Footprint: Length: 6000mm; Width: 3000mm; Height: 2500mm (Customizable)

- Control System: PLC with Touchscreen HMI

- Safety Compliance: Designed with integrated safety features like light curtains, emergency stops, and physical guarding, often meeting CE or equivalent standards. Conforms to ISO 9001 quality management principles.

- Advanced Options: Potential for integration with vision systems for quality checks, adjustable stacking patterns, automatic malfunction diagnostics, and connectivity for production data logging.

Addressing Key Challenges in Steel Tile Handling

Manual or semi-automated handling of steel tiles presents several operational challenges that automated stacking systems directly address:

- Labor Costs & Availability: Reduces dependency on manual labor for repetitive and physically demanding tasks.

- Ergonomics & Safety: Minimizes risks of musculoskeletal injuries associated with lifting heavy or awkward items, a persistent issue highlighted by occupational safety agencies like OSHA. Automation significantly reduces direct human interaction with heavy loads.

- Product Damage: Gentle, precise handling by the machine minimizes scratches, dents, or edge damage compared to manual methods.

- Stack Quality & Consistency: Ensures uniform, stable stacks essential for safe storage, transport, and downstream processes like automated banding or wrapping.

- Production Bottlenecks: Creates a smooth, predictable flow, eliminating inconsistencies inherent in manual stacking speeds. Research in production logistics frequently points to automated material handling as a key enabler for improving overall equipment effectiveness (OEE).

Primary Applications and Industry Impact

The Automatic Bundle Stacking Machine for Steel Tiles delivers significant value across various sectors:

- Metal Roofing Manufacturing: Integrates seamlessly into production lines following roll forming or stamping operations. It enhances throughput, ensures consistent stack quality crucial for packaging and shipping, and accommodates various profiles and sizes, improving line flexibility as noted in publications like The Fabricator.

- Construction Supply Warehousing: Streamlines sorting, stacking, and order preparation in distribution centers. Improves inventory density, reduces handling time, and enhances safety within busy warehouse environments, aligning with trends covered in Modern Materials Handling.

- Prefabricated Building Components: Essential for manufacturers of modular buildings, sheds, or garages requiring precisely stacked components for efficient downstream assembly. Ensures Just-in-Time (JIT) availability of ready-to-use tile bundles, improving assembly line velocity.

By replacing manual effort with reliable automation, this machine contributes to leaner operations, improved workplace safety, and enhanced product quality control – key objectives for modern industrial distributors and manufacturers.

For a detailed consultation on how this technology can be integrated into your specific operation, please contact us.

For more information, feel free to contact info@fhopepack.com.