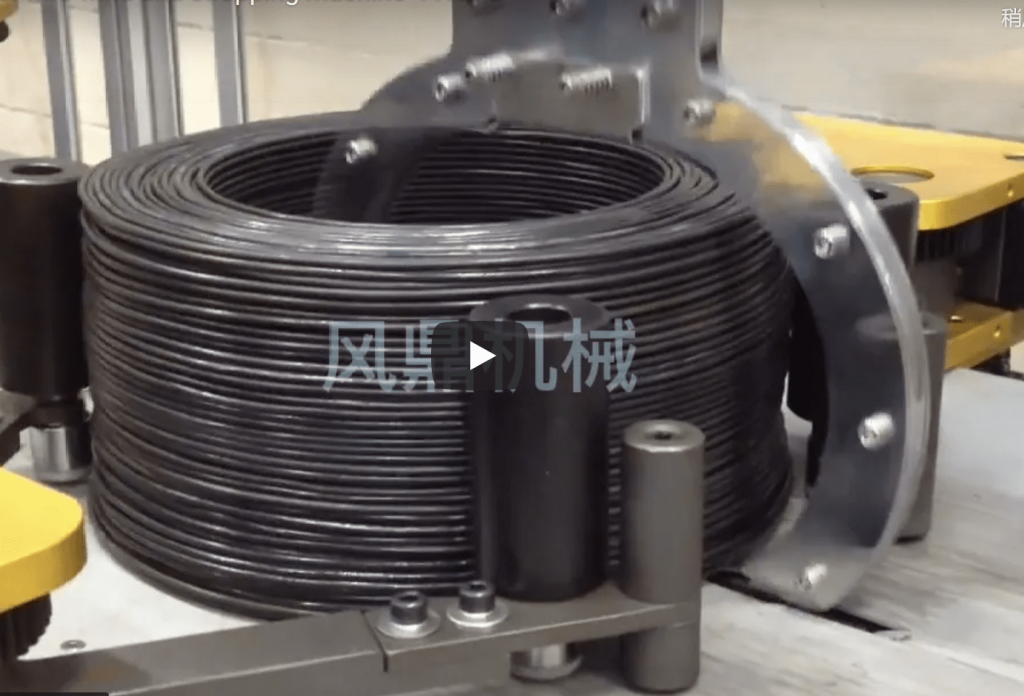

This is a video for Automatic Board Packing Line.

Why Automation in Board Packaging is the Inevitable Choice for Board Companies

In today’s fast-paced industrial world, automation is no longer a luxury—it’s a necessity. For board companies working in industries like printing, packaging, and construction, staying competitive requires the adoption of cutting-edge technologies. Among these, automated packaging systems have emerged as a game-changer. Automation has revolutionized how board companies handle their packaging processes, offering unparalleled efficiency, cost savings, and quality control.

But why is automation in board packaging becoming the inevitable choice for these companies? This article will explore the key reasons behind this shift, delving into its benefits, applications, and transformative impact on the industry. If you’re a board manufacturer or a company still relying on manual or semi-automated systems, this comprehensive guide will help you understand why now is the time to embrace automation.

Table of Contents

- The Growing Demand for Automation in Board Packaging

- Challenges Faced by Manual Packaging Processes

- Benefits of Automation in Board Packaging

- 3.1 Enhanced Efficiency and Speed

- 3.2 Cost Savings and ROI

- Key Features of Automated Board Packaging Systems

- How Automation Improves Product Quality

- The Role of IoT and Smart Technology in Packaging Automation

- Common Applications of Automation in the Board Industry

- Real-World Success Stories of Automated Packaging Adoption

- Overcoming Common Misconceptions About Packaging Automation

- The Future of Automation in Board Packaging

- Conclusion

1. The Growing Demand for Automation in Board Packaging

The global packaging industry is evolving at a breakneck speed. As customer expectations grow, so do the demands for faster, more reliable, and cost-effective packaging solutions. For board companies, where precision and durability are critical, automation offers a way to meet these rising demands.

According to recent studies, the global packaging automation market is projected to reach $72.6 billion by 2028, growing at a compound annual growth rate (CAGR) of 7.5%. This surge is fueled by manufacturers across industries realizing the transformative potential of automation. Board companies are no exception, as they face increasing pressure to optimize their processes and reduce operational costs.

2. Challenges Faced by Manual Packaging Processes

Before diving into the benefits of automation, it’s important to understand the limitations of manual packaging systems. Many board companies continue to rely on labor-intensive processes, which often lead to:

- Inconsistencies in Packaging: Manual processes are prone to errors, resulting in uneven wrapping, incorrect strapping, or misaligned edges.

- High Labor Costs: Dependence on human labor increases operational expenses, especially in regions with high wages.

- Safety Concerns: Handling heavy boards or repetitive tasks manually can pose significant safety risks, leading to workplace injuries.

- Limited Scalability: As demand increases, manual systems struggle to keep up, causing bottlenecks in production.

These challenges not only affect productivity but also hinder a company’s ability to deliver consistent quality. Automation addresses these pain points, making it an inevitable choice for forward-thinking board companies.

3. Benefits of Automation in Board Packaging

3.1 Enhanced Efficiency and Speed

One of the most significant advantages of automation is its ability to dramatically improve efficiency. Automated systems can package boards at speeds far beyond what manual labor can achieve. For instance, an automated board packaging line with features like corner protection devices, vertical wrapping systems, and high-speed strapping machines can process dozens of boards per hour without interruptions.

Automation also eliminates downtime caused by human fatigue, ensuring continuous operation. This is especially crucial for board companies handling large orders or working in time-critical industries like construction and shipping.

3.2 Cost Savings and ROI

While the initial investment in automation may seem steep, the long-term cost savings are undeniable. Automated systems reduce reliance on manual labor, significantly lowering wage expenses. Additionally, they minimize material waste by ensuring precise and consistent packaging.

Here’s a simple cost comparison to illustrate the ROI of automation:

| Cost Factor | Manual Packaging | Automated Packaging |

|---|---|---|

| Labor Costs (Annual) | $50,000-$70,000 | $10,000-$15,000 |

| Material Waste (%) | 5-10% | <1% |

| Packaging Time (per board) | 5-10 minutes | 1-2 minutes |

By streamlining processes and reducing waste, automated systems often pay for themselves within a few years of implementation.

4. Key Features of Automated Board Packaging Systems

Modern automated packaging systems come equipped with advanced features designed to optimize every step of the process. Here are some of the most notable ones:

- Corner Protection Devices: These ensure that the edges of boards are safeguarded from damage during transport.

- Vertical Wrapping Systems: Provides tight and secure wrapping to protect the boards from external elements like dust and moisture.

- Film Covering Systems: Adds an additional protective layer, ideal for boards used in harsh environments.

- Strapping Machines: Ensures that the boards are securely bound, preventing movement during transit.

- PLC-Controlled Operations: Enables precise control and monitoring of the packaging process, ensuring high consistency and accuracy.

These features not only improve the quality of packaging but also reduce the likelihood of damage during shipping and storage.

5. How Automation Improves Product Quality

In industries where boards are often heavy, fragile, or prone to edge damage, maintaining product quality is paramount. Automation ensures consistent packaging quality by eliminating the variability associated with manual processes.

For example, automated systems apply uniform tension during wrapping and strapping, preventing loose packaging that could cause damage during transport. Additionally, features like anti-slip surfaces and load detection sensors add an extra layer of protection, ensuring that the boards remain stable and intact throughout the process.

6. The Role of IoT and Smart Technology in Packaging Automation

The integration of IoT (Internet of Things) and smart technology is taking packaging automation to the next level. IoT-enabled systems allow companies to monitor and control their packaging lines remotely, providing real-time insights into performance metrics such as speed, efficiency, and error rates.

For example, a smart packaging line can detect when a roll of wrapping film is running low and automatically alert operators to replace it—reducing downtime. Additionally, predictive maintenance features analyze machine performance data to identify potential issues before they lead to breakdowns.

With IoT and smart technology, board companies can achieve unprecedented levels of efficiency and reliability.

7. Common Applications of Automation in the Board Industry

Automation isn’t limited to a single type of board or packaging process. Here are some common applications:

| Application | Automation Features | Benefits |

|---|---|---|

| Corrugated Boards | Precision film wrapping, corner protection | Prevents crushing and edge damage |

| Plywood Boards | Heavy-duty strapping machines | Ensures stability during transit |

| Fiber Cement Boards | Moisture-resistant film covering | Protects against environmental factors |

| MDF and Particle Boards | Anti-slip surfaces, load balancing sensors | Reduces risk of roll slippage |

These applications demonstrate the versatility of automated systems in meeting the unique needs of various board types.

8. Real-World Success Stories of Automated Packaging Adoption

Companies that have embraced automation in their packaging processes have seen remarkable improvements. For instance, a leading plywood manufacturer in Europe reported a 40% increase in productivity and a 30% reduction in damaged shipments after implementing an automated packaging line.

Similarly, a corrugated board company in Asia saved over $100,000 annually in labor costs by transitioning to a fully automated system. These success stories highlight the tangible benefits of automation and its ability to transform operations.

9. Overcoming Common Misconceptions About Packaging Automation

Despite its benefits, some companies hesitate to adopt automation due to misconceptions, such as:

- “It’s too expensive.” While the upfront cost is high, the long-term savings in labor, materials, and downtime make it a worthwhile investment.

- “It’s too complicated to implement.” Modern systems are designed for ease of integration, with user-friendly interfaces and comprehensive training programs for operators.

By addressing these misconceptions, board companies can make informed decisions about adopting automation.

10. The Future of Automation in Board Packaging

The future of packaging automation lies in further advancements in AI (Artificial Intelligence), robotics, and sustainability. AI-powered systems will enable even greater precision, while robotic arms will handle complex packaging tasks with ease. Additionally, companies are moving towards eco-friendly packaging materials and energy-efficient systems to reduce their environmental footprint.

As these technologies continue to evolve, automation will become even more indispensable for board companies striving to stay ahead of the competition.

11. Conclusion

Automation in board packaging is no longer just an option—it’s an inevitable choice for companies looking to optimize their processes, reduce costs, and improve product quality. Whether it’s faster packaging speeds, enhanced safety, or reduced material waste, the benefits of automation are undeniable.

By embracing advanced features like IoT integration, corner protection, and smart strapping systems, board companies can future-proof their operations and stay competitive in an increasingly demanding market. If your company hasn’t yet made the leap to automation, now is the time to invest in the technology that will define the future of board packaging.

Automation isn’t just a trend—it’s the foundation of a more efficient and profitable future for board companies worldwide.