Automatic aluminum film applicator and bag packing line video

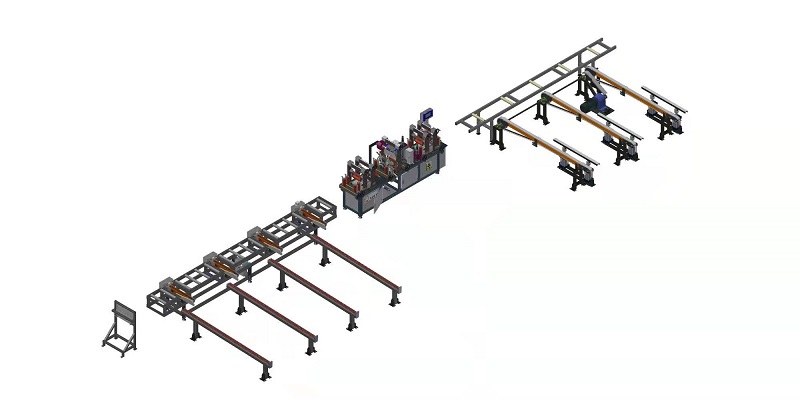

The videos show the packaging process for the aluminum profiles. It comes out from the extruder line. and moving into the wrapping sation.

When the aluminum profile arrived the tranfer table conveyoer that will move the profiles 90 degree for feeding into the film tapping staiton.

The aluminum profile will be picking up one by one and entering into the automatic protective film applicator. The applicator is able automatic checking and cutting the film per profile length. The film tapping application can be done in 1/2/3/4 size or size irrugular shape too.

An automatic aluminum film applicator and bag packing line is a highly sophisticated system designed to streamline the packaging process in industries that require robust moisture and light barrier properties for their products, such as food, pharmaceuticals, and electronics. This system typically integrates a film applicator that automatically cuts and applies aluminum film to the product, followed by a seamless transition to a bagging unit that encloses the product in a protective pouch. Key features often include advanced control systems for precise film placement, integrated sealing technology to ensure air-tight packaging, and conveyor systems for efficient product throughput.

The parameters below do not 100% match the equipment in the video. For exact specifications, please contact us.

- Type: Automatic Film Applicator and Bag Packing Line

- Suitable Film Types: Aluminum, Aluminum Composite

- Product Size Range: Width: 50-300mm; Length: 100-450mm; Height: 10-150mm

- Film Thickness: 30-200 microns

- Packing Speed: Up to 30 packs per minute

- Sealing Technique: Heat seal

- Conveyor Speed: Adjustable, up to 15 meters per minute

- Power Requirements: 220V, 50Hz, single-phase

- Machine Dimensions: Length: 6000mm; Width: 1500mm; Height: 2000mm

- Compliance: ISO 9001, CE Certified

The automatic aluminum film applicator and bag packing line proves exceptionally beneficial in the following applications:

- Pharmaceutical Industry: For pharmaceutical products that require stringent protection against moisture and contaminants, this machine offers an ideal solution. It ensures that sensitive items such as pills, capsules, and powders are securely wrapped in aluminum film, which provides excellent barrier properties, and then sealed within a secondary bag. This dual-layer protection is pivotal in preserving the efficacy and extending the shelf life of pharmaceutical products.

- Electronic Components Packaging: In the electronics industry, where products are highly susceptible to static and moisture damage, the machine’s capability to apply aluminum film precisely helps protect sensitive components like circuit boards and chips. By encasing components in a moisture-barrier film and then packing them into bags, the system significantly reduces the risk of damage due to environmental factors, thus ensuring the integrity of electronic products during storage and transport.

- Food Industry: For food products that require freshness and a long shelf life, such as coffee, snacks, and dried fruits, the aluminum film applicator and bag packing line provides an efficient packaging solution. The aluminum film acts as an excellent oxygen and moisture barrier, preserving the taste, aroma, and quality of food products. The automated bagging ensures that the packaging process is not only fast but also maintains a high standard of hygiene, critical for food safety compliances.

info@fhopepack.com