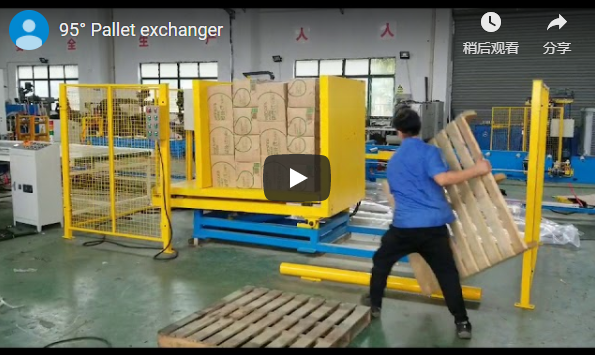

A 95° pallet exchanger is an industrial device designed to rotate and exchange pallets holding goods without disturbing the cargo. The machine typically features a robust construction with a rotating mechanism that can tilt pallets up to 95 degrees. This allows for efficient and safe swapping of pallets from one type to another, such as from wooden to plastic pallets, or for the purpose of replacing damaged pallets. The unit often includes safety guards, a control panel for operation settings, and hydraulic or mechanical lifting and tilting systems to handle various pallet sizes and weights.

The parameters below do not 100% match the equipment in the video. For exact specifications, please contact us.

- Type: Hydraulic Pallet Exchanger

- Pallet Types Compatibility: Wood, plastic, metal

- Maximum Load Capacity: 2000kg

- Tilt Angle: Up to 95 degrees

- Operation: Semi-automatic or fully automatic

- Cycle Time: Approximately 30 seconds per cycle

- Power Requirements: 380V, 50Hz, three phase

- Safety Features: Emergency stop, safety guards, load sensors

- Machine Dimensions: Length: 2300mm; Width: 1500mm; Height: 2000mm

- Control System: Programmable Logic Controller (PLC) with HMI (Human Machine Interface)

The 95° pallet exchanger is particularly useful in various industrial and logistics scenarios. Here are three impactful applications:

- Warehouse Logistics for Food and Beverage Industry: In environments where hygiene is paramount, such as the food and beverage industry, this pallet exchanger allows for the swift and safe swapping of wooden pallets to hygienic plastic ones before entering a clean area. This minimizes contamination risks and adheres to strict industry regulations. The ability to handle loads up to 2000kg ensures that even large quantities of goods can be managed efficiently, which is critical for maintaining the cold chain and product quality.

- Chemical Manufacturing and Handling: Chemical manufacturers often need to replace wooden pallets with more durable plastic or metal options to ensure safety and compliance with handling regulations. The 95° pallet exchanger provides a secure method to do this without manual handling, which can be hazardous in environments dealing with volatile or corrosive substances. The use of load sensors and safety guards adds an additional layer of security, protecting both the product and the personnel.

- Automotive Parts Distribution: In the automotive industry, handling heavy and bulky parts securely is crucial. The pallet exchanger’s capability to tilt and exchange pallets at a 95-degree angle allows for the stable repositioning of loads for further processing or shipping. This reduces the physical strain on workers and decreases the risk of damaging critical parts, thereby improving operational efficiency and reducing costs associated with manual labor and product damage.

https://www.fhopepack.com/pallet-inverter/