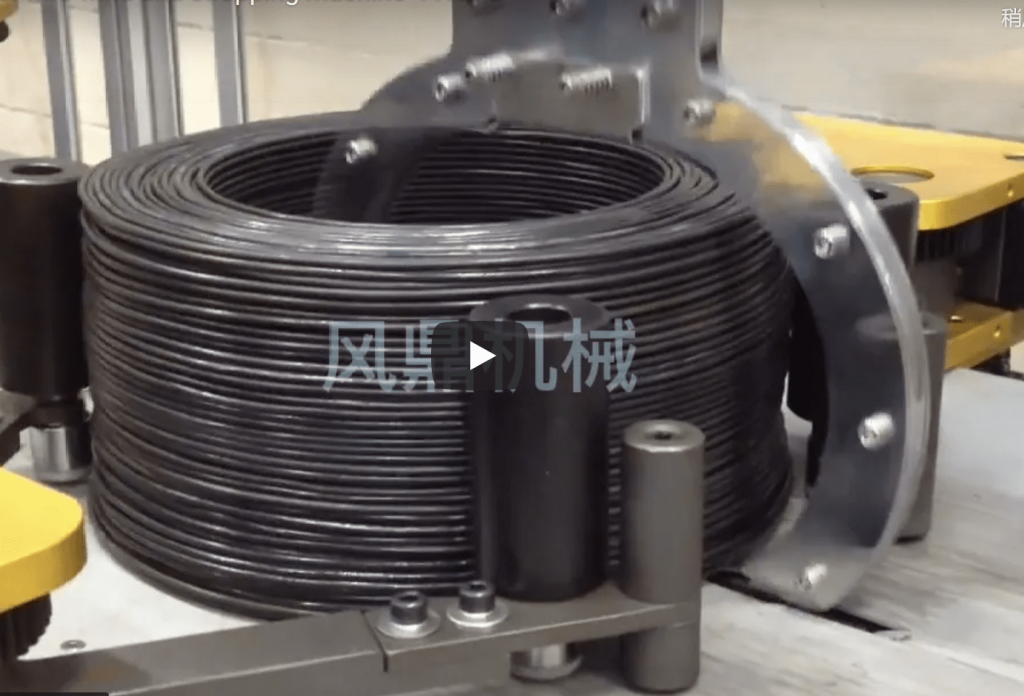

An automatic gas rubber tube coiler and binding machine is specifically engineered to coil and secure lengths of gas rubber tubes efficiently. This machine is equipped with features to handle delicate rubber material, including a tension-controlled coiling system to prevent tube damage. Typically, the structure consists of a coiling unit, a binding mechanism (which could use various materials for secure binding), and a user-friendly control panel, ensuring precise automation and minimal manual intervention.

The parameters below do not 100% match the equipment in the video. For exact specifications, please contact us.

- Type: Automatic Tube Coiler and Binder

- Tube Diameter Compatibility: 10mm to 50mm

- Binding Material Options: Nylon, metal strips, plastic

- Binding Tightness Adjustment: Yes

- Coil Diameter Adjustable: 300mm to 1000mm

- Binding Speed: Up to 30 tubes per minute

- Material Suitability: Rubber, synthetic rubber

- Power Requirements: 110V/220V, 50/60Hz, single phase

- Machine Dimensions: Length: 3000mm; Width: 1200mm; Height: 1800mm

- Machine Weight: Approximately 500kg

The automatic gas rubber tube coiler and binding machine serves several critical functions across various industries. Here are three notable applications:

- Assembly Line Integration for Appliance Manufacturing: This machine can coil and bind rubber tubes at speeds up to 30 tubes per minute, supporting rapid assembly line operations in appliance manufacturing. Tubes with diameters ranging from 10mm to 50mm can be efficiently processed, making it versatile for different product sizes. The effective integration of this machine reduces assembly time and increases productivity, ensuring that appliances like gas stoves and heaters are equipped with properly installed gas tubes.

- Automotive Industry Applications: In the automotive industry, secure and precise handling of rubber gas tubes is essential for safety and functionality. The machine’s capability to adjust coil diameter from 300mm to 1000mm allows it to accommodate various automotive specifications. The binding options further ensure that the tubes are secure and ready for installation, streamlining the manufacturing process for vehicle components such as fuel lines.

- Storage and Transportation Solutions for Gas Tubes: By tightly coiling and binding rubber tubes, this machine minimizes the space required for storage and transportation, which is crucial for manufacturing and distribution firms. Properly coiled and bound tubes are easier to handle, reducing the risk of damage during transit and decreasing overall logistics costs. This application not only protects the material integrity but also improves operational efficiency in supply chain processes.

https://www.fhopepack.com/Automatic-Coiling-Machine/

More information: info@fhopepack.com