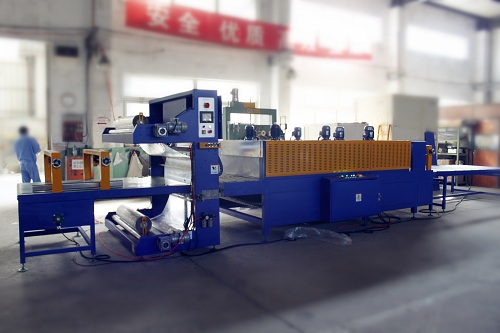

Automated Door Packing Machine

The manufacturing industry has always relied on efficiency to thrive, and automation has been a transformative force in this regard. The rise of automated door packing machines is no exception. With the need to optimize processes, minimize labor dependency, and ensure seamless packaging, businesses are increasingly adopting these automated systems. The question is, why are automated door packing machines critical in modern manufacturing lines?

Streamlined operations, reduced costs, and enhanced precision are some of the tangible benefits of integrating automated door packing machines. They solve the complexities of manual packaging while accelerating production speeds without compromising quality. However, the decision to adopt such machinery requires careful consideration of its long-term impacts and adaptability to a company’s operational growth.

Packaging doors—whether steel, wood, or composite—demands precision and consistency. Any deviation can lead to product damage, delays, or inefficiencies. Automated door packing machines ensure every packaged door meets the required safety and quality standards while keeping up with large-scale production demands. For companies looking to stay ahead, adopting this technology is no longer optional—it’s essential.

[Claim]: Automated door packing machines revolutionize how doors are handled, packed, and delivered, optimizing operational efficiency while ensuring cost-effectiveness.

1. How Do Automated Door Packing Machines Improve Production Quality?

1.1 Enhanced Speed and Consistency

Automated door packing machines offer an unmatched level of speed and precision compared to manual labor. These machines are designed to handle varying door sizes, materials, and weights seamlessly, ensuring that production lines remain uninterrupted. With speeds reaching up to 50 doors per hour in advanced systems, businesses can significantly reduce turnaround times.

More importantly, consistency is achieved without compromising packaging integrity. The repetitive nature of manual work introduces the potential for human error—uneven wraps, loose ends, or misalignments. Automated systems, on the other hand, operate with programmed precision, delivering uniform results every time.

1.2 Cost Reduction Through Automation

Automated door packing machines deliver significant cost reductions over time. Businesses that previously relied heavily on labor-intensive processes often face inefficiencies, such as workforce fatigue, variability in output, and increasing wages. With automation:

|

Cost Factor

|

Manual Process

|

Automated Process

|

|

Labor Costs

|

High

|

Low

|

|

Packaging Speed

|

10-20 doors/hour

|

Up to 50 doors/hour

|

|

Error Rate

|

3-5%

|

0.5%

|

|

Material Wastage

|

Moderate

|

Minimal

|

By reducing these expenses, automated systems pay for themselves over a short period while freeing up workers for more value-added tasks.

1.3 Types of Door Packing Materials and Systems

Automated door packing machines are versatile and adaptable, capable of working with various packaging materials, including:

-

Stretch Films: Provides durable wrapping, suitable for scratch-resistant door finishes.

-

Bubble Wrap: Ensures added cushioning for fragile or specialty doors.

-

Corrugated Sheets: Combines protection and eco-friendliness, ideal for heavy-duty doors.

Each system can integrate material-specific programs, allowing manufacturers to select optimal packaging based on product specifications.

1.4 Advanced Safety Features in Automated Door Packing Machines

Safety is a crucial factor when integrating machinery into high-volume manufacturing lines. Modern automated door packing machines come equipped with advanced features such as:

-

Emergency Stop Buttons: Immediately halts operations to prevent injuries.

-

Sensor-Based Operation: Detects misaligned doors or foreign objects in the packaging zone.

-

Protective Enclosures: Reduces risks from moving components and high-speed rollers.

Additionally, automated systems are designed with user-friendly interfaces, reducing the learning curve for operators while maintaining operational safety.

1.5 Fact or Fiction: Can Machines Replace Human Oversight in Packaging?

True: Machines outperform humans in terms of precision, speed, and consistency. Automation ensures that businesses meet production deadlines without compromising packaging quality.

False: Human oversight is still crucial for quality checks, maintenance, and handling unexpected machine errors. While machines reduce human involvement, experienced operators are still needed to ensure optimal performance and troubleshoot issues.

2. What Are the Key Components of an Automated Door Packing Machine?

2.1 Precision-Control Systems

At the heart of every automated door packing machine is its precision-control system. This component ensures each door is packaged according to exact specifications, regardless of size or material. Equipped with programmable logic controllers (PLCs) and advanced sensors, these systems monitor alignment, wrapping tension, and sealing accuracy.

By continuously adjusting for variations, precision-control systems minimize errors. For example, doors that measure within ±0.5mm tolerance limits are handled flawlessly. This level of control ensures consistency in production lines, avoiding waste due to packaging errors.

2.2 Integration With Conveyor Lines

Seamless integration with conveyor lines is essential for operational efficiency. Automated door packing machines are designed to work alongside existing production conveyors, creating a smooth workflow.

|

Component

|

Function

|

|

Infeed Conveyors

|

Transport doors to the machine

|

|

Centering Systems

|

Align doors before packaging

|

|

Outfeed Conveyors

|

Move packaged doors to the next step

|

Integration reduces the need for manual handling, which can slow down operations. With fully automated workflows, businesses can achieve production rates as high as 60 doors per hour without bottlenecks.

2.3 Energy Efficiency and Sustainability Options

Modern automated door packing machines are engineered to be energy efficient. These machines optimize power usage by operating only during active packaging cycles. Many systems now include eco-friendly options, such as:

-

Low-Power Motors: Reduces energy consumption by up to 30%.

-

Recyclable Packaging Materials: Supports sustainability goals with minimal environmental impact.

-

Standby Modes: Cuts idle power usage by 50%.

Businesses that prioritize energy-efficient machinery not only reduce operational costs but also align with global sustainability initiatives.

2.4 Why Modular Designs Matter for Future-Proofing

Modular designs allow manufacturers to customize automated door packing machines to fit current and future needs. Businesses can add or remove components—such as automated sealing modules, extra rollers, or material feeders—depending on production demands.

Benefits of modular systems include:

-

Scalability: Easily upgrade machines as production grows.

-

Reduced Downtime: Replace faulty modules without disrupting the entire machine.

-

Cost Efficiency: Pay for only the features you need now, with the option to expand later.

Machines with modular flexibility ensure businesses stay agile and responsive to market changes.

2.5 Fact or Fiction: Are Automated Machines Always Energy-Intensive?

True: Older machines may consume significant energy due to outdated motors and inefficient components.

False: Modern automated door packing machines are highly energy-efficient, utilizing smart technologies like standby modes and low-power motors to minimize energy consumption. Investing in new systems often leads to long-term energy savings.

3. How Can Businesses Ensure ROI With Automated Door Packing Machines?

3.1 Measuring Cost-Savings Over Manual Labor

The financial impact of automation is often measured by comparing labor costs to the cost of running automated systems. Labor-intensive processes typically require multiple workers across shifts, whereas a single operator can manage an automated door packing machine.

|

Comparison Factor

|

Manual Labor

|

Automated System

|

|

Workforce Required

|

5-6 workers

|

1-2 operators

|

|

Annual Labor Costs

|

$150,000+

|

$40,000 (machine operation)

|

|

Error-Related Losses

|

Moderate

|

Minimal

|

By eliminating unnecessary labor expenses and increasing output, businesses often see ROI within 12-18 months.

3.2 Identifying Bottlenecks in Existing Packaging Processes

Existing manual packaging processes can create production bottlenecks, slowing output and increasing costs. By conducting a workflow analysis, businesses can pinpoint where delays occur—such as in material preparation or door alignment—and determine how automated machines solve these issues.

For example, automated systems reduce cycle time by 60%, ensuring smooth, uninterrupted packaging. Businesses can achieve greater throughput without expanding labor resources.

3.3 Real-Time Monitoring and Data Analytics

Advanced automated door packing machines now incorporate real-time monitoring systems. These systems track performance metrics such as:

-

Packaging Speed

-

Material Usage Efficiency

-

Error Rates

Data analytics tools allow businesses to identify areas for improvement, predict maintenance needs, and ensure machines operate at peak performance. By leveraging data insights, manufacturers can optimize packaging processes and reduce downtime.

3.4 Maximizing Throughput Without Increasing Downtime

Achieving maximum production output requires machines to operate with minimal interruptions. Automated door packing machines are designed for reliability, incorporating features like:

-

Auto-Calibration: Adjusts settings for different door sizes.

-

Quick Material Reloading: Reduces delays during packaging.

-

Predictive Maintenance: Alerts operators before breakdowns occur.

With these technologies, businesses can ensure high throughput rates while minimizing production downtime.

Two Fact Statement: Can Automation Guarantee 100% Efficiency?

True: Automation reduces errors, increases speed, and delivers consistent results across production lines.

False: No machine achieves absolute perfection. Occasional maintenance and human oversight remain essential for optimal performance.

4. What Should You Look for When Investing in an Automated Door Packing Machine?

4.1 Scalability and Customization Options

One of the key factors to consider when investing in an automated door packing machine is its ability to scale and adapt to your business needs. As production demands grow, machines must offer customization options to handle different door sizes, materials, and packaging specifications.

Scalability ensures businesses do not outgrow their machines prematurely. Customization features such as adjustable rollers, programmable control settings, and modular attachments make it easier to adapt the machine for future requirements. For example, machines capable of switching between stretch film and bubble wrap without manual intervention improve versatility while reducing setup time.

4.2 Comparing Different Brands and Features

Choosing the right brand of an automated door packing machine can be challenging, but comparing features helps narrow down the best options.

|

Feature

|

Brand A

|

Brand B

|

Brand C

|

|

Packaging Speed

|

50 doors/hour

|

60 doors/hour

|

45 doors/hour

|

|

Automation Level

|

Semi-Automatic

|

Fully Automatic

|

Fully Automatic

|

|

Energy Consumption

|

30 kWh/day

|

25 kWh/day

|

35 kWh/day

|

|

Maintenance Requirements

|

Bi-Monthly

|

Monthly

|

Bi-Monthly

|

By evaluating these metrics, businesses can identify machines that offer the best balance of speed, energy efficiency, and maintenance costs. Always prioritize a reputable manufacturer with proven reliability and after-sales support.

4.3 Warranty, Maintenance, and After-Sales Support

Long-term performance hinges on robust warranty and maintenance packages. Before finalizing an investment, ensure the manufacturer offers comprehensive after-sales support, including:

-

Warranty Coverage: A minimum 1-2 year warranty on parts and labor ensures peace of mind.

-

Maintenance Contracts: Scheduled servicing prolongs machine lifespan and reduces unexpected breakdowns.

-

Spare Parts Availability: Quick access to replacement parts minimizes production downtime.

Reliable after-sales support enhances operational stability, especially in high-output manufacturing environments where every minute of downtime impacts revenue.

4.4 Assessing Durability for Long-Term Use

Durability plays a vital role when selecting an automated door packing machine. Machines built with high-quality materials like stainless steel frames and wear-resistant components last longer under heavy use. Additionally, advanced technologies such as corrosion-resistant rollers and temperature-controlled motors improve machine lifespan, especially in demanding production conditions.

Investing in a durable system reduces total cost of ownership by minimizing frequent repairs or early replacements. Businesses benefit from consistent, high-quality performance for years to come.

Conclusion

Automated door packing machines are redefining efficiency and precision in modern manufacturing lines. From improving production speed to ensuring cost-effective operations, these systems are an indispensable asset for businesses aiming to remain competitive.

By understanding the components, key features, and return on investment potential, businesses can make informed decisions that align with their long-term goals.

[Claim]: Investing in a scalable, reliable, and energy-efficient automated door packing machine enables businesses to meet growing demands while maintaining high operational standards.