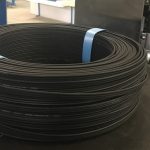

Different types of products require different types of packaging. For example, coil-shaped products need to be wrapped in a spiral eye throug wrapping. This packaging way can be done by stretch rollers fixed on a vertical ring, which allows the coil to pass through the eye for coil whole sides wrapping.

More coil wrapping machine: Just FHOPE

A wire rod coil wrapping machine is a type of packaging equipment designed to wrap wire rod coils with a protective layer of material, such as stretch film. As you mentioned, different types of products require different types of packaging, and for coil-shaped products, a spiral eye-through wrapping method is often used.

The spiral eye-through wrapping method involves passing the coil through a vertical ring that has stretch rollers fixed on it. The ring is positioned in such a way that the coil passes through the center of the ring, allowing the stretch rollers to apply the stretch film to the coil as it rotates. This method ensures that the entire surface of the coil is wrapped, providing complete protection against moisture, dust, and other contaminants.

One advantage of using a wire rod coil wrapping machine with a spiral eye-through wrapping method is the efficiency and consistency of the packaging process. By automating the packaging process, businesses can reduce the amount of time and labor required to wrap each coil manually. Additionally, the stretch film applied by the machine is consistent in thickness and tension, ensuring a uniform and secure wrap for each coil.

Wire rod coil wrapping machines can also be customized to handle different coil sizes and weights, as well as different types of stretch film. Some machines may also offer additional features, such as adjustable tension controls for the film or automatic cutters for the stretch film.

Overall, a wire rod coil wrapping machine with a spiral eye-through wrapping method can be a valuable investment for businesses that need to package wire rod coils on a regular basis. By improving efficiency, reducing labor costs, and ensuring that each coil is properly protected, these machines can help to improve the overall productivity and profitability of the business.