A wire coil wrapping machine for galvanized wire and aluminum wire is a specialized packaging solution designed to provide efficient and reliable protection during transportation and storage. The machine can wrap wire coils in a variety of materials, including stretch film, VCI film, or paper, providing better stability, protection, and corrosion resistance.

The wire coil wrapping machine can wrap wire coils at high speeds, reducing labor costs and improving production efficiency. It can also be operated in automatic or semi-automatic mode, depending on the specific needs of the application. The machine can wrap wire coils in a variety of materials, including stretch film, VCI film, or paper, providing better stability, protection, and corrosion resistance.

The machine provides reliable protection for every shipment, securing the wire coil with a protective covering of film, providing better stability and protection during transportation and storage. The use of VCI film can protect the wire coils from corrosion during transportation and storage, reducing the number of damaged coils and saving money.

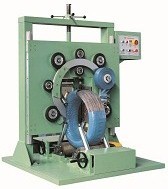

The wire coil wrapping machine is cost-effective, as it reduces material costs and the number of damaged coils during transportation, saving money and improving customer satisfaction. It is also easy to operate, with a turntable that rotates the wire coil, allowing it to be wrapped in film from all sides. The film is stretched tightly around the coil, providing a secure and stable packaging solution.

Overall, the wire coil wrapping machine for galvanized wire and aluminum wire is a versatile, customizable, and efficient solution for wire coil packaging during transportation and storage. With its improved efficiency, reliable protection, corrosion resistance, cost-effectiveness, and easy operation, this machine can significantly improve the packaging process and reduce costs for businesses.

Wire coil wrapping machine video for small coil objects packaging.

The wire wrapping machine is used to securely package coiled objects such as springs, tubing, or wire. The machine feeds wire along the side of the coiled object while simultaneously rotating the object. This wraps the wire around the coil in a tight spiral pattern, binding it and holding its shape. The wire feed and coil rotation can be precisely controlled to achieve consistent wrapping results. Once wrapped, the coiled object stays firmly bound together, even with repeated handling or shipping. Wire wrapping machines automate this packaging process and produce stable, professionally wrapped coil packages.

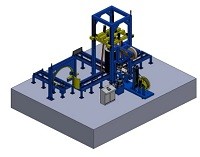

Wire coil wrap equipment for increasing the packing speed with less film

.jpg)