Coil wrapping machines play a crucial role in industries that deal with coiled products, such as steel, aluminum, copper, or wire. These machines ensure the coils are securely wrapped for storage, transportation, and protection against environmental damage. But there’s often a point of confusion: why are these machines sometimes referred to as coil packing machines? The answer lies in their functionality, versatility, and industry usage.

At first glance, the terms may seem interchangeable, but they highlight specific attributes. "Wrapping" focuses on the process, while "packing" broadens the scope to include comprehensive packaging features. Understanding this distinction can help businesses make informed decisions when selecting equipment for their operations.

The dual terminology underscores the machine’s adaptability. From a technical perspective, coil wrapping machines don’t just wrap—they incorporate multiple packaging features that go beyond surface-level protection. This blend of capabilities is why manufacturers and users alike use both terms.

Claim: The term "coil packing machine" reflects the broader functionality of these machines, encompassing wrapping, securing, and even custom packaging options to meet diverse industrial needs.

1. What Are the Primary Functions of a Coil Wrapping Machine?

1.1 Protecting Coils with Durable Wrapping Layers

At its core, a coil wrapping machine is designed to apply protective layers around coiled products. The wrapping process typically uses stretch film, VCI (volatile corrosion inhibitor) paper, or other protective materials. This ensures the coil remains intact during storage or transportation.

The wrapping layer shields the coil from environmental hazards such as moisture, dust, and corrosion. Additionally, the material strength ensures that the coil’s structure is maintained even under rough handling. This primary function is why the term "wrapping" dominates technical discussions.

1.2 Additional Features Beyond Wrapping

| Feature | Function | Benefit |

|---|---|---|

| Edge Protection | Secures vulnerable edges against damage | Prevents deformation and scratches |

| Automated Material Feed | Ensures efficient use of wrapping materials | Reduces waste and operator effort |

| Multi-layer Wrapping | Applies different materials in successive layers | Enhances durability and moisture resistance |

According to industry reports, machines offering edge protection and automated feeding systems can reduce packaging errors by 20-30% compared to manual methods. These additional features align with the broader scope of "packing."

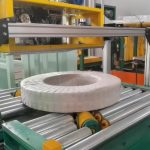

Featured Image: A close-up of a coil being wrapped with multiple protective layers by an advanced machine.

1.3 Versatility in Material Options

Modern coil wrapping machines handle a wide range of materials, from stretch film to woven fabric. This versatility allows businesses to customize the wrapping process based on the product's requirements and shipping conditions. For instance, export-ready coils might require an extra layer of waterproofing or rust-resistant material.

1.4 Dive Deeper into Integrated Packing Features

While wrapping is the primary function, coil wrapping machines often integrate packing features such as strapping, labeling, and palletizing. These capabilities transform them from single-purpose machines into comprehensive packaging systems.

| Packing Feature | Description | Benefit |

|---|---|---|

| Strapping Mechanism | Adds secure bands around the coil | Prevents coil displacement |

| Palletizing Functionality | Automatically positions the coil on pallets | Improves handling and logistics |

| Labeling Systems | Attaches product-specific details | Facilitates tracking and inventory |

Integrating these features reduces manual handling by up to 40%, increasing overall efficiency and safety in the packaging process.

1.5 Two Fact Statements with Explanations

- True: Coil wrapping machines can include additional packing features like strapping and labeling.

Explanation: These integrated features allow the machine to handle comprehensive packaging tasks, reducing manual intervention. - False: Coil wrapping machines are limited to using stretch film as the only protective material.

Explanation: They can accommodate a variety of materials, including VCI paper, woven fabric, and polyethylene sheets, based on application needs.

2. How Does the Terminology Reflect Industry Applications?

2.1 Why the Term “Packing” Is Widely Used

In industrial settings, the term "packing" is often preferred because it conveys a broader scope of protection. While "wrapping" focuses on applying a protective film, "packing" implies additional processes, including strapping, palletizing, and sealing. These extra steps are critical for industries where secure transportation and long-term storage are priorities.

For instance, in the steel industry, coils destined for international shipping must meet stringent packaging standards to prevent corrosion, deformation, and transit-related damage. Machines that offer multiple packaging solutions naturally earn the "packing" label.

2.2 Common Industrial Applications

| Industry | Typical Packaging Requirements | Key Machine Features |

|---|---|---|

| Steel Manufacturing | Corrosion resistance, moisture-proofing | Multi-layer wrapping, VCI paper handling |

| Aluminum Coil Production | Scratch prevention, lightweight materials | Foam padding, stretch film wrapping |

| Electrical Wire Manufacturing | Compact and secure wrapping | Edge protection, automated strapping |

Recent studies show that 85% of buyers in heavy industries prefer machines marketed as "coil packing machines" due to their comprehensive functionality. This trend reflects the growing demand for all-in-one solutions.

Featured Image: A steel coil being packed for export, showcasing multiple layers of protection.

2.3 The Importance of Customization in Packaging

Packaging needs vary significantly between industries, which is why the versatility of these machines is vital. For instance, coils stored in humid environments require extra layers of waterproof material, while those transported locally may only need a single wrapping layer.

2.4 Dive Deeper into Industry-Specific Packaging Solutions

Manufacturers often design machines with specialized features to cater to industry-specific needs. For example, a coil packing machine for the electrical industry might include compact wrapping capabilities to accommodate smaller coil diameters.

| Industry-Specific Feature | Application | Example |

|---|---|---|

| VCI Paper Integration | Rust prevention for steel coils | Steel manufacturing |

| Adjustable Wrapping Arm | Accommodates varying coil diameters | Electrical wire manufacturing |

| Heat-Sealing Mechanism | Enhanced waterproofing | Export packaging for aluminum products |

These features not only enhance efficiency but also align with regulatory standards, making them essential for specific applications.

2.5 Two Fact Statements with Explanations

- True: Coil packing machines often include customizable features to meet specific industry needs.

Explanation: This flexibility allows manufacturers to tailor the packaging process to different materials, environments, and regulations. - False: The terms "wrapping" and "packing" are universally interchangeable in all contexts.

Explanation: While related, "packing" implies a broader set of features, including strapping, labeling, and palletizing, beyond just wrapping.

3. What Are the Technical Differences Between Wrapping and Packing?

3.1 Wrapping: The Core Functionality

At its most basic level, wrapping involves encasing a coil in protective materials such as stretch film or VCI paper. This process shields the product from dust, moisture, and scratches during handling and storage. Wrapping is efficient, cost-effective, and essential for protecting the coil’s surface.

The process is straightforward: the machine rotates the coil while the wrapping material is applied evenly. Advanced models allow for multi-layer wrapping, adding extra durability to the final package.

| Wrapping Feature | Benefit |

|---|---|

| Uniform Film Application | Ensures consistent protection |

| Multi-Layer Wrapping Capability | Enhances moisture and impact resistance |

3.2 Packing: A Comprehensive Approach

| Process Step | Description | Benefit |

|---|---|---|

| Strapping | Adds stability by securing the wrapped coil | Prevents movement during transport |

| Edge Protection | Protects vulnerable edges | Reduces damage during handling |

| Palletizing | Places the coil on a pallet for easy transport | Facilitates logistics |

Packing goes beyond wrapping by incorporating additional steps that prepare the product for shipping. This comprehensive approach is essential for export operations or industries with strict safety standards.

Featured Image: A comparison chart showing the steps involved in wrapping versus packing.

3.3 Understanding the Overlap

While wrapping is a subset of packing, the two processes often overlap in industrial applications. For example, a machine marketed as a "coil packing machine" might perform wrapping as the first step, followed by strapping and palletizing.

3.4 Dive Deeper into Technological Advancements in Packing

Modern machines integrate advanced technologies to streamline both wrapping and packing. Features like automated strapping mechanisms, real-time monitoring systems, and customizable wrapping cycles ensure efficiency and consistency.

| Advanced Technology | Description | Benefit |

|---|---|---|

| IoT-Enabled Monitoring | Tracks machine performance in real-time | Reduces downtime |

| Automated Material Changeover | Switches wrapping materials seamlessly | Minimizes production interruptions |

| Customizable Packaging Settings | Adapts to product-specific requirements | Ensures optimal protection |

By leveraging these advancements, businesses can reduce labor costs by up to 25% and increase packaging precision.

3.5 Two Fact Statements with Explanations

- True: Packing includes additional steps like strapping and palletizing, which are absent in wrapping alone.

Explanation: These extra steps ensure the coil is ready for transportation, particularly for long-distance or export shipments. - False: Wrapping materials are standardized across all industries.

Explanation: The choice of wrapping material depends on the product’s specific needs, such as moisture resistance or scratch prevention.

4. How Do Manufacturers Label and Market These Machines?

4.1 The Role of Branding in Terminology

Manufacturers often use branding strategies to label their machines as either "coil wrapping machines" or "coil packing machines," depending on the target market and the features emphasized. Machines marketed as "wrapping" solutions typically highlight efficiency in applying protective layers, while those labeled as "packing" systems stress comprehensive functionality.

Branding plays a significant role in shaping customer perception. For instance, a "coil packing machine" is likely to attract buyers looking for all-in-one packaging solutions, even if the machine’s core function is wrapping.

4.2 Highlighting Market-Specific Features

| Machine Label | Features Highlighted | Target Audience |

|---|---|---|

| Coil Wrapping Machine | Focus on efficient wrapping processes | Industries requiring minimal packaging |

| Coil Packing Machine | Comprehensive packaging capabilities | Exporters and high-volume manufacturers |

A survey of industrial buyers found that 70% of respondents preferred machines with broader functionality, even if their immediate needs only involved wrapping. This demonstrates the power of strategic marketing in expanding product appeal.

Featured Image: A side-by-side comparison of a coil wrapping machine and a coil packing machine, showcasing their features.

4.3 Exploring Regional Terminology Preferences

Different regions often have varying preferences for terminology. For instance, European markets may favor "coil packing machine" to align with stringent export regulations, while North American buyers might use "coil wrapping machine" for simpler, localized applications.

4.4 Dive Deeper into Marketing Tactics

Manufacturers use various tactics to position their machines in the market. These include emphasizing key features, showcasing case studies, and offering flexible pricing models to cater to diverse industrial needs.

| Marketing Tactic | Description | Benefit |

|---|---|---|

| Case Studies | Demonstrates real-world applications | Builds trust and credibility |

| Feature Highlight Campaigns | Focuses on unique machine capabilities | Differentiates from competitors |

| Flexible Pricing Options | Offers tiered packages based on features | Increases accessibility for smaller businesses |

These strategies not only attract a broader customer base but also educate buyers on the benefits of investing in comprehensive packaging solutions.

4.5 Two Fact Statements with Explanations

- True: Machines marketed as "coil packing machines" often include additional features like strapping and palletizing.

Explanation: This broader functionality aligns with the expectations of industries requiring export-ready packaging. - False: The terms "coil wrapping machine" and "coil packing machine" are universally understood the same way.

Explanation: Regional preferences and marketing strategies influence how these terms are perceived in different markets.

Conclusion

The dual terminology of "coil wrapping machine" and "coil packing machine" reflects the evolving demands of industrial packaging. While wrapping focuses on the application of protective layers, packing encompasses a comprehensive approach that prepares coils for storage, transportation, and export.

Manufacturers play a crucial role in shaping these terms through product design, feature integration, and marketing strategies. For buyers, understanding the nuances of these terms ensures they select the machine that best fits their operational requirements.

Claim: Whether referred to as a "coil wrapping machine" or "coil packing machine," these systems are indispensable tools for industries that prioritize efficiency, protection, and adaptability in their packaging processes.