An orbital wrapping machine, also known as a horizontal stretch wrapper, is an indispensable packaging tool across numerous industries. Its primary function is to secure products using stretch film, but its true value lies in its remarkable flexibility. These machines are engineered to wrap a diverse range of items, effectively handling products of various shapes, sizes, and weights – from compact bundles to extensive industrial materials like pipes, lumber, and profiles. Understanding the scope of products compatible with orbital wrappers is essential for selecting the appropriate packaging equipment to enhance operational efficiency and ensure product integrity during transit and storage.

This guide explores the wide array of products effectively packaged using orbital wrapping machines. We will examine applications ranging from long, flat materials to irregularly shaped objects and heavy-duty loads, highlighting how the machine's adjustable parameters cater to diverse industrial packaging requirements.

1. The Adaptability of Orbital Wrapping Machines

Orbital wrapping machines are celebrated for their adaptability in packaging diverse products. Unlike specialized machinery, they are not confined to a single product type but offer versatile solutions across multiple sectors.

- Cross-Industry Application: Key industries benefiting include logistics, building materials, furniture manufacturing, automotive, and metal processing.

- Handling Diverse Geometries: Their ability to securely wrap long items (e.g., timber, extrusions), flat panels, or complex shapes (e.g., pipes, assembled parts) makes them a cornerstone of many packaging lines. This flexibility allows businesses to protect various product types efficiently using a single machine type.

2. Packaging Long and Flat Products

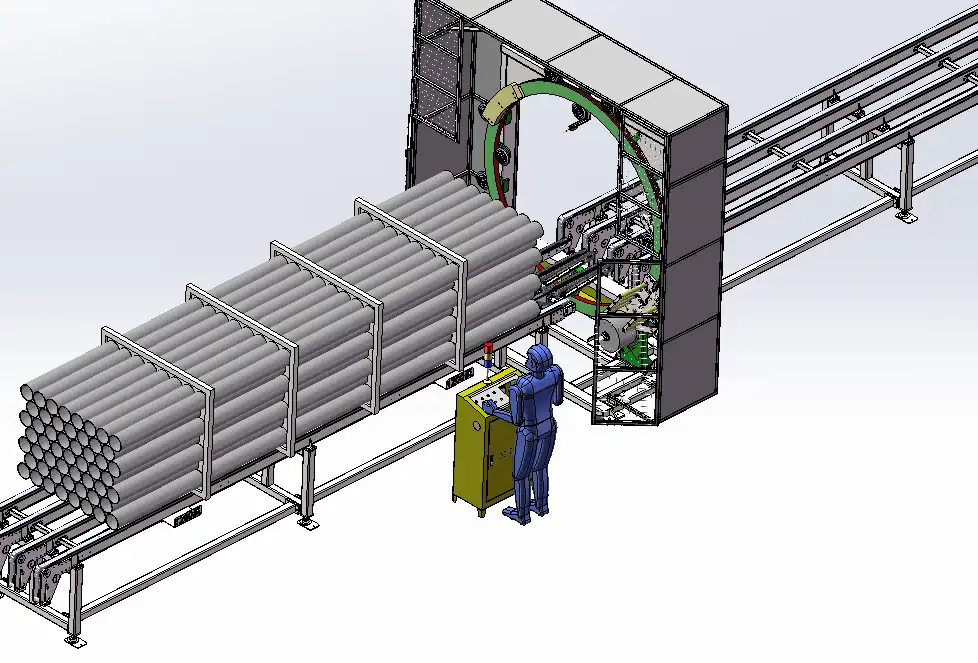

A primary application for orbital wrapping machines is securing long and flat items, which often pose challenges for conventional packaging methods.

- Suitable Products:

- Wooden boards, lumber, and panels

- Metal beams, profiles, and extrusions

- Plastic pipes and conduits

- Doors and windows

- Protection Benefits: Orbital wrappers apply a consistent, tight layer of stretch film along the entire length. This safeguards surfaces from abrasion, dirt, moisture, and other environmental contaminants during handling and shipping, preserving product quality. Consistent wrapping is crucial for maintaining the structural integrity of bundled long items.

3. Securing Irregularly Shaped Objects

Orbital wrappers excel at packaging items with non-uniform or irregular shapes, where manual wrapping or other automated methods might be inefficient or ineffective.

- Common Applications:

- Furniture components

- Automotive parts (e.g., exhaust pipes, bumpers)

- Assembled machinery or sub-assemblies

- Bundled tubing or wiring harnesses

- How it Works: The stretch film conforms closely to the product's contours as the wrapping ring orbits around it. This ensures that even items with protrusions or complex geometries are fully encased and stabilized, preventing movement and potential damage.

4. Bundling Multiple or Small Items

While adept at handling large products, orbital wrappers are also highly effective for bundling smaller items together or securing delicate goods.

- Bundling Applications:

- Small hardware components

- Lengths of trim or molding

- Sets of tools or parts

- Handling Delicate Goods: For items like electronics components, decorative pieces, or sensitive materials, precise control is key. Orbital wrappers feature adjustable parameters:

- Film Tension Control: Allows operators to apply the optimal amount of force, securing the items without causing crushing or deformation.

- Ring Speed Adjustment: Controls the wrapping speed for gentle handling.

- Conveyor Speed: Manages the throughput rate based on product needs. These settings ensure fragile goods are wrapped securely yet carefully.

5. Stabilizing Heavy-Duty Materials

Orbital wrapping machines are frequently employed to package heavy and bulky industrial materials requiring robust containment.

- Typical Materials:

- Construction materials (e.g., rebar bundles, structural steel)

- Metal rods, bars, or coils

- Heavy pipes or concrete sections

- Bundled raw materials

- Secure Containment: These machines apply multiple layers of high-strength stretch film, creating a durable package capable of withstanding rigorous handling, outdoor storage, and long transport distances. Reinforced machine frames and components are often used for applications involving significant weight and stress.

6. Wrapping Textiles and Rolled Goods

The consistent tension and coverage provided by orbital wrappers make them suitable for packaging textiles, fabrics, carpets, and other rolled materials.

- Product Examples:

- Rolls of carpet or vinyl flooring

- Bolts of fabric or industrial textiles

- Rolled insulation or roofing materials

- Benefits: Wrapping protects these materials from dust, dirt, and moisture. It also prevents rolls from unraveling or telescoping during handling, ensuring they remain clean, intact, and ready for use or sale. The wrap can be applied without excessive compression, preserving the material's quality.

7. Securing Items for Palletization (Through-the-Eye Wrapping)

While distinct from standard turntable or rotary arm pallet wrappers, orbital machines can play a role in preparing goods for pallet shipping, particularly through "through-the-eye" wrapping or bundling items before they are placed on a pallet.

- Specific Applications:

- Wrapping hollow items like large tires or coils placed on a pallet.

- Bundling multiple long items (like pipes or lumber) that will subsequently be moved as a single unit, potentially on a pallet or via forklift directly.

- Advantage: This method can provide load stability and unitization in ways standard pallet wrapping cannot achieve for certain product types, ensuring items are tightly secured before or during palletization.

8. Protecting Furniture and Large Household Items

Bulky, heavy, and often susceptible to surface damage, furniture and large appliances benefit significantly from the protective capabilities of orbital wrapping.

- Furniture Protection: Items like tables, chairs, sofas, cabinets, and bed frames can be wrapped to shield surfaces from scratches, scuffs, dust, and moisture during warehousing and delivery. The film conforms to irregular shapes, providing comprehensive coverage.

- Appliance Wrapping: Large appliances such as refrigerators, washing machines, dryers, and ovens require robust packaging. Orbital wrapping secures loose parts (like cords) and protects finished surfaces from impact and environmental factors.

9. Customizing Solutions for Specialized Products

The adaptability of orbital wrapping technology allows for customization to meet the unique requirements of specialized industries and products.

- Aerospace and Automotive: Precision components often require specific film types and controlled tension to prevent damage and contamination. Custom guarding or handling features may be integrated.

- Pharmaceuticals and Medical: For sterile or sensitive products, machines can be adapted for cleanroom environments or specific packaging protocols to ensure product safety and compliance.

- Unique Geometries: Manufacturers with highly unusual product shapes may work with suppliers to develop tailored wrapping sequences or machine modifications for optimal results.

10. Conclusion: A Versatile Solution for Diverse Packaging Needs

Orbital wrapping machines offer exceptional flexibility, reliability, and security for packaging an extensive range of products. From long profiles and irregularly shaped components to heavy industrial materials and delicate bundles, these machines provide efficient, customizable solutions tailored to specific operational needs.

Investing in the right orbital wrapping equipment enhances product protection, streamlines packaging workflows, potentially reduces labor costs associated with manual wrapping, and ensures goods arrive at their destination in optimal condition. This makes them a valuable asset for improving packaging quality and efficiency across diverse industries.