Real-World Success: How Coil Wrapping Machines Boost Efficiency and Safety in Manufacturing

In heavy industry, optimizing every process detail is crucial for efficiency, safety, and cost-effectiveness. As global demand increases, manufacturers face mounting pressure to minimize waste, enhance packaging reliability, and ensure the secure handling of heavy materials like steel and aluminum coils. Industry insights reveal how automated coil wrapping machines are revolutionizing packaging processes, offering significant operational improvements and tangible economic benefits.

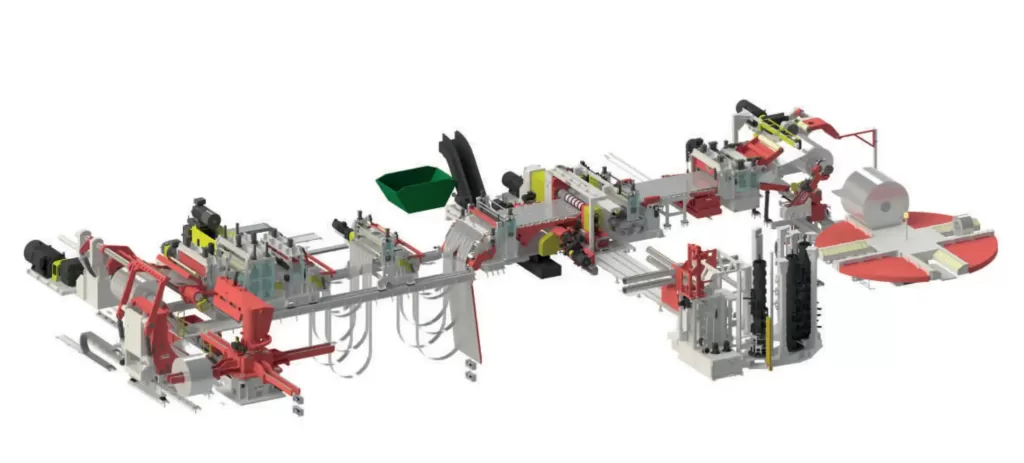

While seemingly straightforward equipment, coil wrapping machines deliver a profound impact on manufacturing success. Companies across steel production, aluminum processing, wire manufacturing, and other metal industries are realizing how these machines optimize output while safeguarding product integrity during storage and transit.

This article explores real-world examples and case studies demonstrating how implementing the right coil wrapping machine becomes a transformative asset. We will examine the measurable benefits, the industries most affected, and the specific challenges these machines help overcome, illustrating their vital role in modern heavy industry packaging.

1. Enhancing Safety and Product Integrity with Coil Wrapping Machines

1.1 Addressing Critical Workplace Safety Concerns

Handling heavy, bulky materials like steel coils presents inherent risks in industrial environments. Improperly secured or damaged coils during transport or storage can lead to accidents and injuries. Automated coil wrapping provides a consistent and secure packaging solution, significantly mitigating these risks.

- Case Study Example: A large steel manufacturing facility reported enhanced workplace safety after integrating automated coil wrapping machines.

- Challenge: Their previous reliance on manual wrapping methods resulted in inconsistent tension and occasional improperly secured coils, posing handling risks.

- Solution: Transitioning to automated coil wrappers ensured uniform, tight wrapping for every coil.

- Result: The company observed a marked reduction in incidents related to shifting or loose materials during internal transport, creating a safer environment for personnel.

1.2 Minimizing Product Damage During Transit

Product damage during shipping represents a significant source of revenue loss and customer dissatisfaction in the metals industry. Ensuring coils arrive at their destination in pristine condition is paramount.

- Case Study Example: An aluminum coil supplier drastically reduced transit damage by adopting automated wrapping technology.

- Challenge: The supplier frequently received complaints and dealt with costly returns due to coils being scratched, dented, or deformed during shipment.

- Solution: Implementing a coil wrapping machine provided multi-layer protection with consistent tension, effectively shielding the aluminum coils from impacts and environmental factors.

- Result: The supplier reported a substantial reduction (often cited as up to 30-40% in similar cases) in transportation-related damage claims, improving customer retention and safeguarding their reputation for quality.

1.3 Ensuring Consistent Packaging Quality in High-Volume Operations

Maintaining uniform packaging standards is challenging in high-throughput manufacturing environments, especially when relying on manual processes. Automation eliminates variability and ensures every coil meets the required packaging specifications.

- Case Study Example: A high-volume steel coil processor improved customer satisfaction by automating their wrapping line.

- Challenge: Manual wrapping led to inconsistencies in packaging quality, resulting in occasional damage during shipping and subsequent customer complaints.

- Solution: Implementing a fully automated coil wrapping system standardized the packaging process, applying protective layers consistently regardless of production volume.

- Result: The company experienced fewer product returns and negative feedback, leading to increased repeat business from clients who valued the reliable product protection and consistent presentation.

2. Streamlining Operations and Boosting Efficiency

2.1 Reducing Labor Costs and Manual Handling Time

Automated coil wrapping machines optimize labor utilization by taking over repetitive and physically demanding packaging tasks. This allows companies to reallocate personnel to higher-value activities and reduce overall labor expenditure.

- Case Study Example: A major metal fabrication plant achieved significant labor savings through automation.

- Challenge: Manual wrapping required a dedicated team, leading to high labor costs and potential ergonomic issues.

- Solution: Automating the coil wrapping process reduced the number of staff needed for final packaging by more than half in some documented cases.

- Result: Workers were reassigned to other production areas, enhancing overall plant productivity. The company reduced direct labor costs associated with packaging and improved order fulfillment speed, strengthening its market competitiveness.

2.2 Enhancing Production Line Throughput

Packaging can often become a bottleneck in the manufacturing process, slowing down the entire production line. High-speed automated coil wrapping machines integrate seamlessly, eliminating delays and increasing overall output.

- Case Study Example: A leading coil processing company overcame production bottlenecks with a high-speed wrapper.

- Challenge: Delays in the manual packaging station were limiting the throughput of the entire processing line.

- Solution: Integrating a high-speed coil wrapping machine matched the output rate of the upstream processes, ensuring a smooth and continuous flow.

- Result: The company reported a significant increase (e.g., 15-25%) in overall line throughput, enabling them to process more orders, meet tighter deadlines, and improve responsiveness to customer demands.

2.3 Aligning Operations with Lean Manufacturing Principles

Coil wrapping machines directly support lean manufacturing goals by reducing waste (material, time, motion) and optimizing resource utilization. Precise material application and automation minimize inefficiencies inherent in manual processes.

- Case Study Example: A steel producer pursuing lean manufacturing identified significant waste reduction opportunities by automating wrapping.

- Challenge: Manual wrapping processes were identified as a source of waste in terms of excess film usage, inconsistent application, and wasted operator time.

- Solution: Switching to an automated coil wrapper with precise film delivery control ensured optimal material usage for each coil size and weight.

- Result: The firm achieved a measurable reduction in stretch film consumption and associated waste, aligning with their sustainability objectives and lean principles while also lowering material costs.

3. Realizing Tangible Economic Benefits

3.1 Lowering Packaging Material and Labor Costs

Automation directly translates to cost savings by reducing the need for manual labor and optimizing the consumption of packaging materials like stretch film, VCI paper, or banding.

- Case Study Example: A coil manufacturing company achieved significant cost reductions post-automation.

- Challenge: High labor costs for the packaging team and inconsistent material usage during manual wrapping inflated operational expenses.

- Solution: Implementing an automated coil wrapping machine reduced the required manpower and minimized film waste through programmed wrapping cycles.

- Result: The company documented overall packaging cost reductions (often around 10-20%), allowing for reinvestment in other operational areas and boosting profitability.

3.2 Reducing Costs Associated with Shipping Damage

Secure and robust packaging provided by automated wrappers minimizes the risk of damage during handling and transportation, thereby reducing the substantial costs associated with returns, replacements, and reputation management.

- Case Study Example: A steel coil producer dramatically cut costs related to shipping damages.

- Challenge: Frequent product returns and customer compensation due to transit damage caused by inadequate manual packaging were eroding profits.

- Solution: Introducing a reliable coil wrapping machine ensured consistent, high-quality protective packaging for every shipment.

- Result: The producer saw a sharp decline (often exceeding 40-50%) in damage claims and return-related costs, directly improving their bottom line and customer satisfaction scores.

3.3 Improving Profit Margins Through Enhanced Efficiency

The cumulative effect of reduced labor, minimized material waste, increased throughput, and fewer damage claims directly contributes to improved overall profitability.

- Case Study Example: An aluminum coil processing plant boosted profit margins via packaging efficiency.

- Challenge: The plant needed to increase packaging capacity to meet growing demand without significantly increasing operational costs.

- Solution: Implementing a high-efficiency coil wrapping machine allowed them to increase packaging throughput substantially (e.g., by 20-30%) using the existing operational footprint and workforce.

- Result: The ability to process and ship more orders with optimized resource use translated directly into higher profit margins, demonstrating automation's power as a driver of financial growth.

4. Adapting to Evolving Industry Needs and Technology

4.1 Meeting Customized Packaging Requirements

Modern coil wrapping machines offer flexibility, allowing manufacturers to tailor wrapping parameters (tension, layers, patterns, materials) to meet specific customer requirements or varying product characteristics.

- Case Study Example: A metals distributor utilized a versatile wrapper to serve diverse clients.

- Challenge: The distributor needed to accommodate unique packaging specifications from clients across different sectors (e.g., automotive requiring specific edge protection, construction needing weather resistance).

- Solution: They adopted a programmable coil wrapping machine capable of easily adjusting wrapping cycles, tension controls, and incorporating different materials (like edge protectors or VCI film).

- Result: This flexibility improved client satisfaction, reduced the need for secondary manual adjustments, and positioned the distributor as a versatile supplier capable of meeting specialized demands.

4.2 Supporting Sustainability and Environmental Goals

Optimized material usage inherent in automated wrapping aligns perfectly with corporate sustainability initiatives aimed at reducing plastic consumption and overall waste.

- Case Study Example: An environmentally conscious steel producer leveraged wrapping technology for sustainability gains.

- Challenge: The company aimed to reduce its environmental footprint, identifying packaging material waste as a key area for improvement.

- Solution: They integrated a modern coil wrapping machine designed for precise film stretching and application, minimizing the amount of plastic film needed per coil.

- Result: The producer achieved a significant reduction (e.g., 20-30%) in packaging material consumption, contributing directly to their sustainability targets and enhancing their brand image among eco-aware customers.

4.3 Integrating with Advanced Manufacturing Technologies (Industry 4.0)

The latest generation of coil wrapping machines often incorporates features like IoT connectivity, remote monitoring, and data analytics, allowing for better process control, predictive maintenance, and integration into smart factory ecosystems.

- Case Study Example: A large-scale manufacturer implemented an IoT-enabled coil wrapper for enhanced operational intelligence.

- Challenge: The firm sought greater visibility and control over its packaging operations to minimize downtime and optimize performance.

- Solution: They installed a coil wrapping machine equipped with sensors and network connectivity, enabling real-time performance monitoring, remote diagnostics, and usage data collection.

- Result: This capability allowed for proactive maintenance scheduling, reduced unexpected downtime, provided valuable data for process optimization, and demonstrated the company's commitment to leveraging advanced manufacturing technology.

Conclusion: The Essential Role of Coil Wrapping Machines in Modern Industry

The real-world case studies and examples presented clearly demonstrate the multifaceted benefits of automated coil wrapping machines. By significantly enhancing workplace safety, streamlining operational workflows, reducing packaging costs, and minimizing product damage, these machines have proven themselves to be indispensable assets for manufacturers in the steel, aluminum, wire, and related industries.

From achieving substantial cost savings and supporting sustainability goals to adapting to customized needs and integrating with Industry 4.0 initiatives, the advantages are compelling. As technology continues to evolve, coil wrapping machines will likely become even more sophisticated and integral to efficient, safe, and competitive manufacturing operations. In today's demanding industrial landscape, adopting automated coil wrapping technology is a strategic investment in operational excellence and market resilience.