Handling steel coils requires attention to safety and efficiency. Improper loading can cause damage to the coils or lead to accidents. So, what are the key precautions to ensure proper loading?

When loading steel coils, it is essential to follow proper procedures to prevent damage and ensure safety. Using the right equipment, securing the load, and maintaining proper positioning are key to success.

Before you proceed with loading steel coils, it’s critical to understand the precautions necessary to protect both the coils and your workers. Whether it’s ensuring proper coil positioning or securing the load properly, these steps can prevent costly damage and reduce injury risks.

Ensuring Safe Coil Positioning: Best Practices for Loading Steel Coils

Proper coil positioning is a crucial step in the loading process. Coils that are improperly positioned can roll, shift, or even topple, causing accidents or damage. Proper positioning not only ensures the safety of your team but also protects the integrity of the steel coil.

The safe positioning of steel coils is vital for preventing accidents and minimizing the risk of damage. Correctly placing the coil on a pallet or transport platform is the first step in a successful load.

Why Proper Coil Positioning Matters

Coil positioning is key to ensuring both the safety and efficiency of the loading process. Here’s why:

- Stability: Coils need to be placed in a way that prevents them from rolling or shifting during transit. Proper positioning helps maintain stability throughout the entire process.

- Prevention of Damage: Misalignment can lead to coils getting damaged due to improper weight distribution. Correct positioning ensures that the load remains secure and the coil is protected.

- Safety: Proper positioning helps reduce the risk of accidents, as workers are less likely to be caught off guard by a coil that shifts unexpectedly.

By following proper guidelines for coil positioning, you can make sure the coils are secure and stable, ultimately contributing to smoother and safer operations.

Preventing Coil Damage During Loading: Key Safety Measures

One of the most common concerns when loading steel coils is preventing damage. From dents to scratches, the steel surface can be easily harmed during handling. That’s why adopting effective measures to prevent coil damage is essential.

Taking key precautions can greatly reduce the likelihood of damaging steel coils during loading. Simple measures such as using appropriate lifting equipment and padding surfaces can make a significant difference.

How to Prevent Damage While Loading

Here are some key strategies to minimize damage during the loading process:

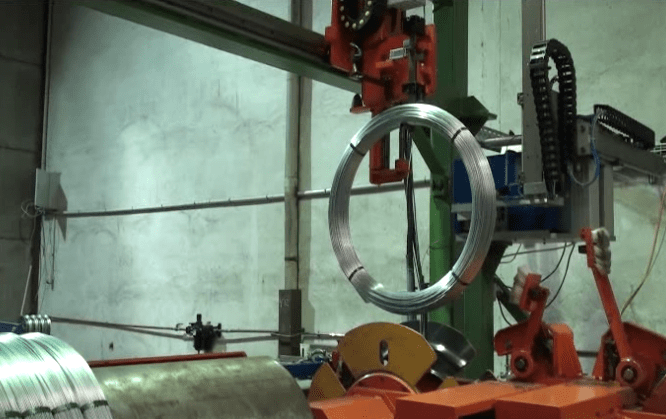

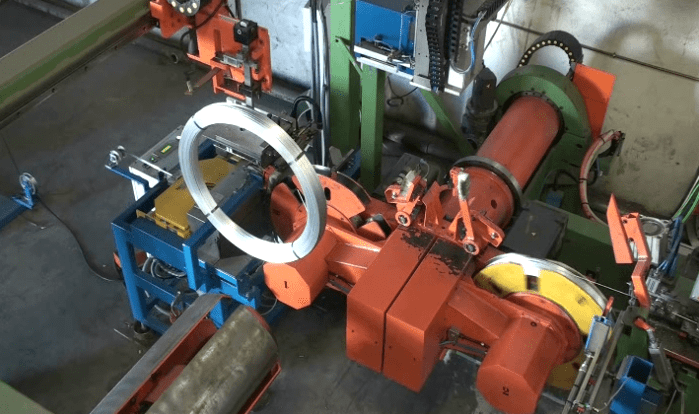

- Use Proper Lifting Equipment: Always use equipment that’s designed to lift and handle steel coils. For instance, coil lifters or manipulators are made for safely moving steel coils without damaging them.

- Padding and Protection: Before loading, consider using protective covers or padding on the coils and surfaces to prevent scratches or dents.

- Avoid Impact: Never drop or forcefully move steel coils during loading. The impact can cause permanent damage, which could lead to costly repairs or rejections.

Implementing these simple yet effective measures can go a long way in protecting the quality of your steel coils and minimizing losses during the loading process.

Handling Heavy Coils Safely: Essential Precautions and Equipment

Loading heavy steel coils presents its own unique challenges. These coils are not only difficult to handle manually but also pose risks of serious injury. Therefore, it’s crucial to use the proper equipment and follow safety precautions.

When handling heavy coils, using the right tools and safety measures is key to preventing accidents and ensuring efficient loading. Lifting devices and proper safety gear are essential in these scenarios.

How to Safely Handle Heavy Steel Coils

The safe handling of heavy steel coils requires planning and the right tools. Here’s a breakdown of what you need to ensure safety during loading:

- Use Appropriate Lifting Equipment: For heavy coils, coil lifters, upenders, or manipulators are necessary to lift and position the coils safely. Never rely on manual labor alone.

- Team Coordination: Handling heavy coils should always involve coordination among team members. Clear communication and proper team alignment help reduce the risk of accidents.

- Personal Protective Equipment (PPE): Workers should always wear appropriate PPE such as gloves, steel-toed boots, and hard hats to minimize injury risks while loading coils.

By using the right equipment and following established safety protocols, you can ensure that your team handles heavy coils with maximum safety and efficiency.

Conclusion

Loading steel coils requires attention to detail and a commitment to safety. From ensuring proper positioning and protecting the coils from damage to using the right equipment for heavy coils, every step plays a vital role in minimizing risks. By following these precautions, you can ensure safe and efficient loading operations.