In a world driven by efficiency and precision, choosing the right coil wrapping machine is more than a matter of convenience—it’s a strategic decision that impacts your entire packaging process. With evolving technology and an emphasis on operational excellence, it’s essential to identify the features that deliver maximum value for your investment.

When I first started exploring coil wrapping machines, I was overwhelmed by the endless specifications and options. Questions like “Do I need automation?” and “How can this machine support my business goals?” kept circling in my mind. It took careful analysis and hands-on experience to understand the nuances of these machines and their transformative potential.

The truth is, the right coil wrapping machine doesn’t just wrap—it optimizes. It brings reliability, speed, and consistency to your operations, reducing waste and improving output. But how do you sift through the noise to find the one that suits your needs? Let’s unravel this together.

1. What Makes Durability a Critical Factor?

1.1 The Role of Sturdy Construction

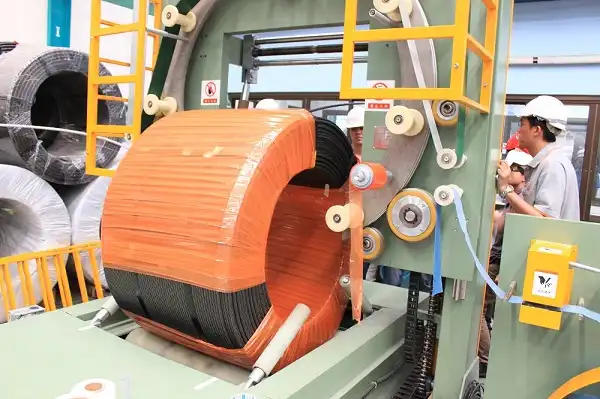

Durability begins with the machine’s construction. From its frame to internal mechanisms, a coil wrapping machine should be designed to withstand the wear and tear of heavy industrial use. Machines built with high-quality steel and corrosion-resistant coatings stand out for their long-lasting performance. This translates into fewer breakdowns, reduced maintenance costs, and consistent output.

I’ve seen operations that overlook this factor, opting for cheaper, less durable machines. Within months, they face costly repairs and downtime that far exceed their initial savings. Investing in robust construction saves you from this avoidable pitfall.

1.2 How Material Quality Affects Longevity

The materials used in the wrapping process, such as rollers and belts, must also meet durability standards. Machines that integrate reinforced or wear-resistant parts ensure the longevity of these components, even under demanding conditions.

In one instance, I worked with a company handling abrasive materials like steel coils with sharp edges. Their initial machine couldn't endure the workload, leading to frequent replacements. Upgrading to a more durable model transformed their operations, cutting downtime by over 30%.

1.3 Why Maintenance Accessibility Matters

Even the most durable machines require occasional upkeep. A machine designed with accessible components makes maintenance faster and more efficient. Features like easily removable panels, clearly labeled parts, and a comprehensive manual can significantly reduce repair time, keeping your operations on schedule.

When I evaluated machines for my operation, I prioritized models with a modular design. This decision proved invaluable when a minor issue arose during peak production; the quick fix kept the line running with minimal disruption.

2. How Important is Automation in Today’s Machines?

2.1 Streamlining Processes with Automation

Automation has revolutionized packaging systems by removing human error and significantly increasing efficiency. Coil wrapping machines with advanced automation capabilities—such as programmable wrapping patterns, automated loading systems, and smart sensors—enhance precision and consistency.

In my experience, adding an automated system not only streamlined operations but also allowed employees to focus on higher-value tasks. Instead of manually monitoring the wrapping process, the machine's intuitive controls ensured optimal output without oversight, reducing labor costs by 20%.

2.2 How Smart Features Drive Efficiency

Smart sensors and IoT-enabled machines have become game-changers in packaging operations. These features optimize wrapping by detecting irregularities, adjusting film tension, or even alerting operators when maintenance is needed.

For instance, I’ve witnessed operations where smart sensors detected anomalies like uneven coil surfaces, preventing improper wrapping and potential damages during transport. These real-time adjustments significantly reduced wastage and customer complaints.

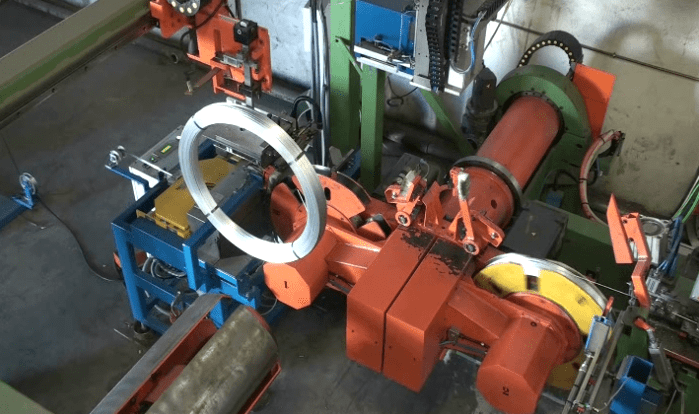

2.3 Why Versatility Matters in Automation

Automation shouldn’t just be efficient—it should be flexible. Machines with programmable interfaces and the ability to handle varying coil sizes and wrapping materials deliver unparalleled versatility.

One manufacturer I worked with opted for a machine that supported multiple wrapping modes. This flexibility allowed them to switch seamlessly between product lines, boosting their productivity and expanding their market reach without investing in additional equipment.

3. Why Should You Consider Energy Efficiency?

3.1 How Energy Efficiency Impacts Costs

Energy efficiency is a critical factor in today’s coil wrapping machines, not just for reducing costs but also for meeting sustainability goals. Machines equipped with energy-saving motors, intelligent standby modes, and optimized power usage significantly cut operational expenses.

I recall working with a facility where an older, energy-intensive machine inflated monthly utility bills by nearly 15%. After switching to a more energy-efficient model, their expenses dropped considerably, proving how impactful this feature can be over time.

3.2 The Environmental Benefits of Energy-Saving Machines

Sustainability is no longer optional—it’s an expectation. Machines designed with eco-friendly technologies, like low-energy consumption drives and recyclable wrapping materials, contribute to reducing your carbon footprint.

One supplier I consulted integrated an energy-efficient machine into their operations, which significantly reduced their greenhouse gas emissions. This move not only enhanced their reputation among eco-conscious clients but also qualified them for government incentives for sustainable practices.

3.3 Maximizing ROI with Energy Efficiency

Energy-efficient machines offer long-term returns on investment. By lowering utility costs, reducing material waste, and ensuring compliance with green regulations, they deliver value far beyond their initial price.

In my own operations, choosing an energy-saving model allowed us to reinvest savings into other critical areas, like employee training and process optimization. It wasn’t just a machine upgrade—it was a strategic decision that bolstered overall profitability.

4. How Does Adaptability Impact Your Long-Term ROI?

4.1 The Value of Customization

Adaptability starts with customization. Machines that can be tailored to specific needs—whether it’s the size of the coils, wrapping patterns, or integration with existing systems—enhance operational flexibility and efficiency.

I once helped a business struggling with inconsistent wrapping due to varying coil sizes. Transitioning to a machine with adjustable parameters resolved their issues instantly, ensuring uniform results across all products.

4.2 The Role of Modular Design in Scalability

Modular designs are an unsung hero of adaptability. Machines with interchangeable parts and expandable functionalities grow with your business, eliminating the need for frequent replacements.

For instance, I worked with a company that started with a basic wrapping model but later upgraded it with automation and sensor systems. This scalability saved them from purchasing an entirely new machine, ensuring continuity in operations while supporting growth.

4.3 Why Future-Proofing is Essential

Future-proofing your coil wrapping machine ensures its relevance in the face of evolving technologies. Machines that support software updates, new material types, and advanced connectivity options provide a competitive edge.

In one memorable case, a business opted for a future-ready machine with IoT capabilities. As their industry adopted smarter packaging systems, this machine integrated seamlessly, keeping them ahead of the curve and maintaining their market position.

Conclusion

Choosing the right coil wrapping machine is a decision that demands careful consideration of both present needs and future growth. From ensuring durability and embracing automation to prioritizing energy efficiency and adaptability, each feature contributes to streamlining operations, reducing costs, and enhancing overall productivity.

[Claim]

The perfect coil wrapping machine isn’t just a tool—it’s an investment in the future of your business. By focusing on key features that align with your operational goals, you can unlock unparalleled efficiency, sustainability, and profitability. Make your choice wisely, and you’ll see the impact ripple through every aspect of your operations.

Get Your Best Solution !