In the heart of a bustling warehouse, where efficiency meets the demands of high-volume operations, every piece of equipment serves a purpose. Amid the automation marvels, the pallet flipping machine stands as a silent yet impactful contributor. Its role transcends the mundane task of flipping pallets—it touches the very essence of operational metrics, from productivity to safety.

Have you ever wondered how a seemingly simple machine can transform complex processes? Let’s explore its significance through metrics that matter.

It’s not just about flipping pallets; it’s about redefining workflows, reducing human error, and unlocking potential in logistics and manufacturing environments.

The machine is the unsung hero that keeps industries ticking, ensuring KPIs are not just met but exceeded. Before diving into its deeper implications, let’s get a clearer picture of the operational landscapes it serves.

1. How Does a Pallet Flipping Machine Improve Operational Efficiency?

Streamlining Workflow with Automated Precision

A pallet flipping machine isn’t just a tool; it’s an orchestrator of seamless operations. Imagine a scenario where production halts because a batch of goods requires manual intervention to correct a misaligned load. The downtime costs spiral. A flipping machine eliminates such delays, flipping and realigning pallets in seconds with unmatched precision.

The result? A streamlined workflow that allows workers to focus on value-added tasks instead of repetitive labor.

Boosting Throughput Without Compromising Quality

Throughput is a critical metric in any operational setting. The faster goods move through production and logistics, the greater the revenue potential. Pallet flipping machines shine in environments where speed is essential, yet quality cannot be compromised. By automating the flipping process, they ensure uniformity, reduce rework, and maintain a consistent flow of goods, even under high-pressure timelines.

Dive Deeper into Adaptability Across Industries

One of the standout qualities of pallet flipping machines is their adaptability. From food and beverage industries, where hygiene standards are paramount, to heavy manufacturing, where handling precision matters, these machines adapt to various load types and configurations effortlessly. Their versatility directly impacts operational metrics, making them indispensable in modern warehouses.

2. Why Is Safety Enhanced by Pallet Flipping Machines?

Reducing Workplace Injuries Through Automation

Manual pallet flipping is not only time-intensive but also risky. Workers face potential injuries due to lifting heavy loads, repetitive motions, and accidental drops. With a pallet flipping machine, these risks diminish. The machine handles the heavy lifting, ensuring safety protocols are met and workers remain injury-free.

It’s not just about reducing injuries; it’s about fostering a culture where safety is prioritized without compromising efficiency.

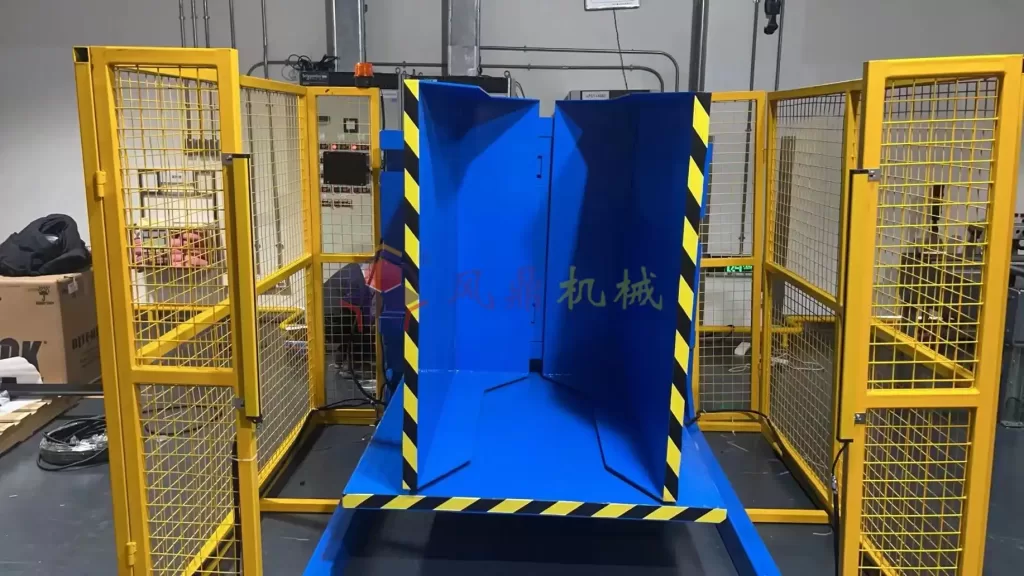

Creating a Safer Workspace Through Stability

When dealing with unstable or unevenly loaded pallets, accidents can happen. A flipping machine stabilizes and secures loads during the flipping process, mitigating the risk of falls or shifts. This stability is crucial in high-speed environments where minor errors can have major consequences.

Dive Deeper into Compliance with Safety Standards

In many industries, safety isn’t just a priority; it’s a regulatory requirement. Pallet flipping machines are designed with compliance in mind, featuring safety guards, automated locking mechanisms, and fail-safes. Their integration ensures that companies not only meet but exceed safety benchmarks, avoiding costly violations and building trust with employees and stakeholders alike.

3. What Are the Cost Benefits of Using a Pallet Flipping Machine?

Cutting Labor Costs Without Sacrificing Productivity

One of the most immediate financial benefits of a pallet flipping machine is the reduction in labor costs. Tasks that once required multiple workers can now be completed by a single operator or, in some cases, entirely automated. This efficiency frees up manpower for other critical roles, ultimately optimizing workforce allocation and reducing overhead expenses.

Imagine a facility where a team spends hours manually flipping pallets. By introducing a flipping machine, those hours turn into minutes, slashing costs while maintaining—or even improving—output levels.

Reducing Product Damage for Better ROI

Handling errors during manual flipping can lead to damaged goods, impacting profitability and customer satisfaction. A pallet flipping machine minimizes this risk by handling loads with precision. By safeguarding products during the flipping process, it ensures that companies experience fewer losses, maximizing their return on investment.

Dive Deeper into Long-Term Maintenance Savings

While initial investment in a pallet flipping machine might seem significant, the long-term savings are undeniable. These machines are built for durability and require minimal maintenance compared to the cumulative costs of labor and potential damage over time. Advanced models with self-diagnostics further reduce downtime, ensuring consistent operations and protecting profitability.

4. How Does a Pallet Flipping Machine Contribute to Sustainability Goals?

Lowering Energy Consumption in Operations

Modern pallet flipping machines are designed with energy efficiency in mind, consuming less power while delivering superior performance. This feature aligns with sustainability goals, reducing the carbon footprint of warehouses and manufacturing facilities. Lower energy usage doesn’t just benefit the environment; it also translates to cost savings over time.

Sustainability isn’t just a trend; it’s a necessity for businesses aiming to thrive in a market where environmental impact is under constant scrutiny.

Supporting Reuse of Pallets and Materials

In industries where pallets are reused, ensuring their longevity is crucial. Improper handling can render pallets unusable, leading to waste and additional costs. A pallet flipping machine ensures pallets are handled gently and evenly, prolonging their lifecycle and reducing the need for replacements. This directly supports a company’s waste reduction initiatives and sustainability metrics.

Dive Deeper into Meeting ESG (Environmental, Social, and Governance) Standards

Incorporating a pallet flipping machine into operations demonstrates a commitment to environmental and social responsibility. By enhancing efficiency and reducing waste, businesses can align with ESG standards, attracting eco-conscious clients and investors. This integration is not just about metrics; it’s about building a reputation for responsible operations in a competitive market.

Conclusion

Meeting and Exceeding Key Operational Metrics with Pallet Flipping Machines

Pallet flipping machines are more than equipment; they are strategic assets in achieving key performance indicators. By improving efficiency, enhancing safety, reducing costs, and supporting sustainability, these machines address the diverse challenges faced by modern industries. Their integration into workflows not only optimizes operations but also future-proofs businesses against evolving demands.

[claim] Investing in a pallet flipping machine is not merely an operational upgrade—it’s a strategic decision to elevate productivity, safety, and sustainability while building resilience in a competitive marketplace.

Get Your Best Solution !