Vertical Type Coil Wrapping Machines

Coil wrapping machines are essential in many industries for packaging large coils of materials like wire, steel, and cable. These machines help in efficiently wrapping coils in protective materials to ensure they stay clean and undamaged during storage or transportation. There are different types of vertical coil wrapping machines, each designed to handle the wrapping process in a unique way. Here, we will explore three main types: machines with the ring mouth down, machines with the ring mouth up, and machines where the wrapping station itself moves.

1. Coil Wrapping Machine with Ring Mouth Down

This type of machine is designed with the ring mouth positioned downwards. The ring mouth is the gap in the ring that allows it to pass through the coil's inner diameter (ID). With the ring mouth facing down, the coil can be easily loaded onto the machine from above. This setup is particularly useful for heavier coils that are difficult to lift manually. The gravity helps in securing the coil as it sits naturally against the base, making the wrapping process smoother and quicker.

Physical Dimensions:

- Machine Height: 1800 mm

- Machine Width: 1500 mm

- Machine Length: 1800 mm

- Total Weight: Approx. 800 kg

Coil Handling Specifications:

- Maximum Coil Weight: 3000 kg

- Maximum Coil Diameter: 1600 mm

- Maximum Coil Width: 100-300 mm

- Minimum Coil Diameter: 600 mm

- Coil Inner Diameter Range: 400 mm to 700 mm

Performance:

- Wrapping Speed: 20-35 rpm (adjustable)

- Cycle Time: Approx. 3-5 minutes per coil (depending on coil size and wrapping material)

2. Coil Wrapping Machine with Ring Mouth Up

In contrast, some machines feature the ring mouth facing upwards. This configuration is suitable for operations where coils are delivered via conveyor belts or other automated systems that align with the top part of the machine. The coil is placed into the ring from above, and the wrapping material is applied as the ring spins around the coil. This setup can be advantageous for lighter coils or in facilities where overhead handling equipment is prevalent.

Wrapping Material:

- Material Type: Stretch film, plastic film, paper, etc.

- Film Roll Width: Up to 500 mm

- Core Diameter: 76 mm (standard)

Power and Control:

- Power Supply: 380V, 3 Phase, 50 Hz

- Control System: PLC controlled with touchscreen interface

- Safety Features: Emergency stop, safety guards, and sensors

Additional Features:

- Loading System: Overhead crane or forklift compatible

- Operator Interface: User-friendly touchscreen for easy setup and control

- Maintenance: Easy access panels for routine maintenance

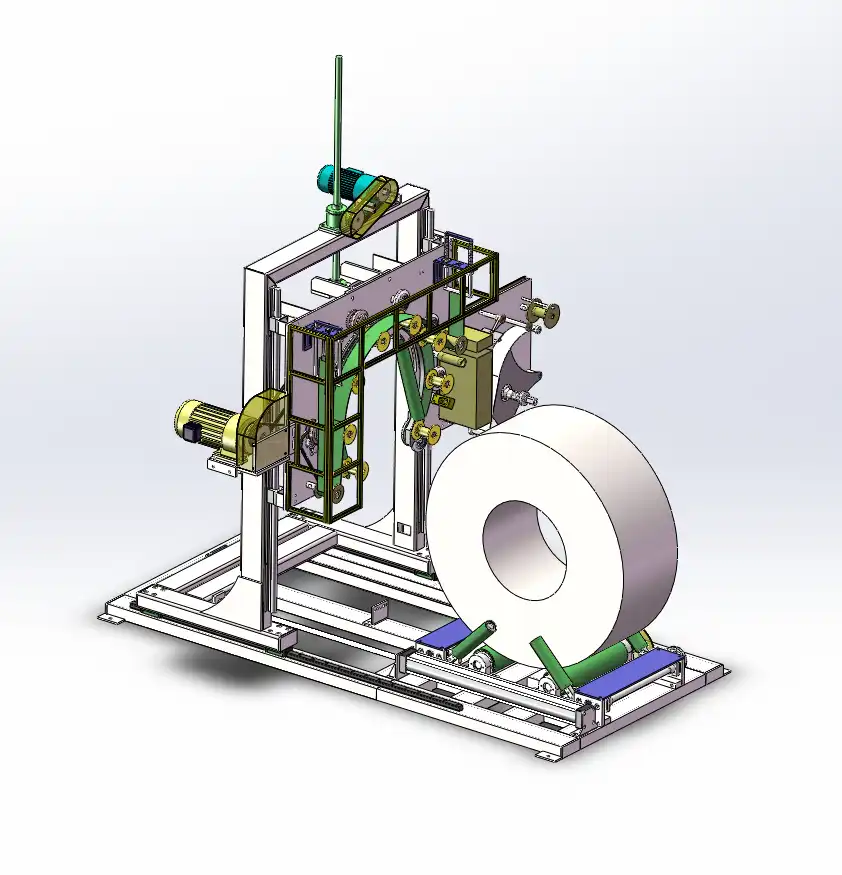

3. Coil Wrapping Machine with Wrapping Station Movement

The third type involves machines where the wrapping station itself moves around a stationary coil. The coil remains fixed, and the ring with the wrapping material moves vertically along the height of the coil. This design is particularly effective for very large or heavy coils that are not easily rotated. By moving the wrapping station instead of the coil, manufacturers can ensure a consistent and tight wrap, regardless of the coil size or weight.

Each type of vertical coil wrapping machine offers distinct advantages depending on the specific needs of the operation, such as the coil size, weight, and the layout of the manufacturing facility. Understanding these differences is crucial for choosing the right machine that increases efficiency, safety, and product protection during the wrapping process.

Coil Handling Specifications:

- Maximum Coil Weight: 2000 kg

- Maximum Coil Diameter: 1400 mm

- Maximum Coil Width: 750 mm

- Minimum Coil Diameter: 500 mm

- Coil Inner Diameter Range: 350 mm to 600 mm

Performance:

- Wrapping Speed: 25-40 rpm (adjustable)

- Cycle Time: Approx. 2-4 minutes per coil (depending on coil size and wrapping material)

Wrapping Material:

- Material Type: Stretch film, polyethylene film, craft paper

- Film Roll Width: Up to 600 mm

- Core Diameter: 76 mm (standard)