How Versatile Semi-Automatic Bagging Machines Boost Packaging Speed and Accuracy

In today's fast-paced manufacturing and packaging world, efficiency is key. Companies are constantly on the lookout for ways to streamline their processes, increase productivity, and maintain high-quality standards. Enter the versatile semi-automatic bagging machine – a game-changer in the packaging industry. This article will delve deep into how these machines are revolutionizing packaging operations, boosting speed and accuracy, and providing a competitive edge to businesses of all sizes.

Understanding Semi-Automatic Bagging Machines

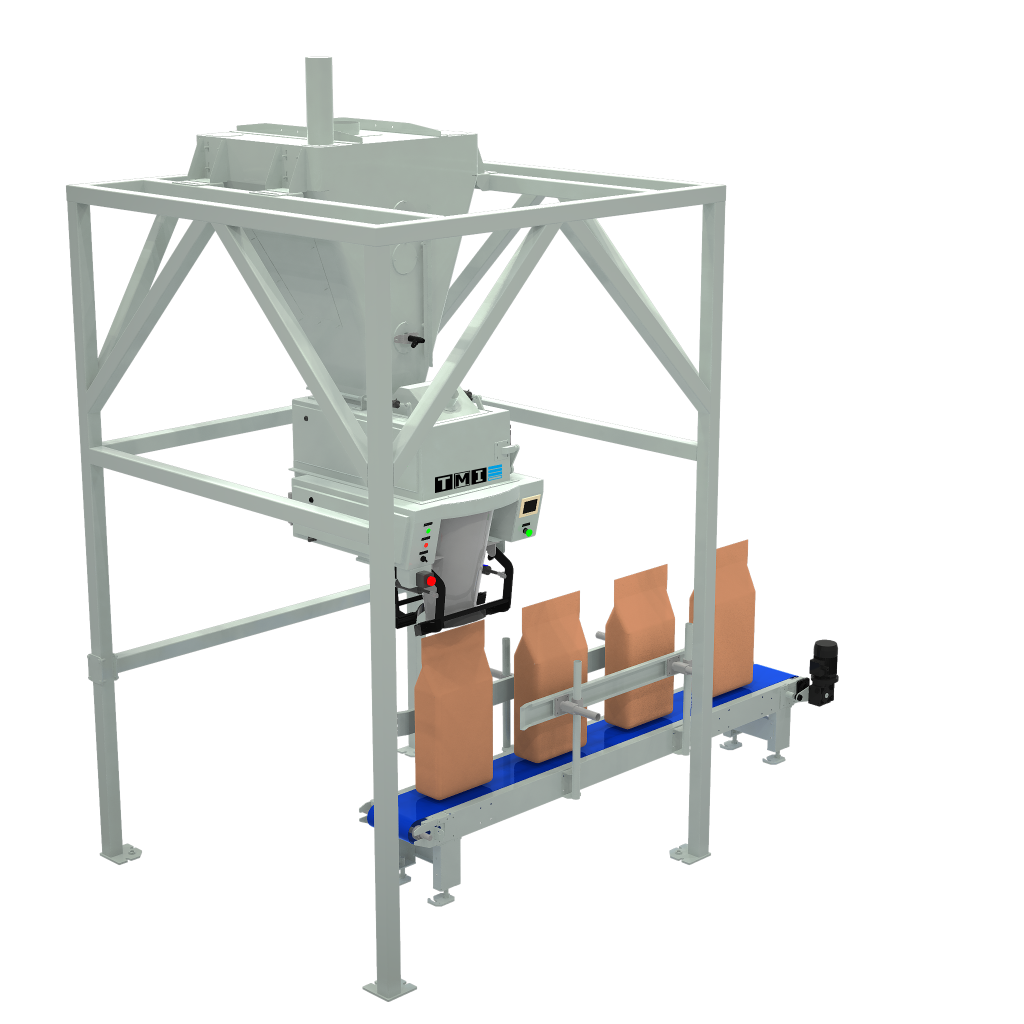

Before we dive into the benefits and applications, let's first understand what a semi-automatic bagging machine is. These machines are designed to automate a significant portion of the bagging process while still allowing for some manual intervention. They strike a perfect balance between fully manual operations and completely automated systems.

Key features of semi-automatic bagging machines include:

- Adjustable bag size settings

- Automated bag opening and filling

- Semi-automated sealing mechanisms

- Customizable fill rates and weights

- User-friendly interfaces

These machines are called "semi-automatic" because they require an operator to initiate each bagging cycle and often to place the filled bags onto a conveyor or into boxes. This human element allows for greater flexibility and oversight in the packaging process.

The Evolution of Packaging Technology

To truly appreciate the value of semi-automatic bagging machines, it's important to understand the evolution of packaging technology:

- Manual bagging: The traditional method, labor-intensive and prone to inconsistencies.

- Basic filling aids: Simple machines that help with filling but still require significant manual labor.

- Semi-automatic bagging machines: Our focus today, offering a blend of automation and manual control.

- Fully automatic bagging lines: High-speed, fully automated systems for large-scale operations.

Semi-automatic bagging machines represent a sweet spot for many businesses, offering significant improvements over manual methods without the complexity and cost of fully automated systems.

Boosting Packaging Speed: The Numbers Game

One of the primary advantages of semi-automatic bagging machines is the dramatic increase in packaging speed. Let's break down the numbers:

- Manual bagging: Typically 5-10 bags per minute

- Semi-automatic bagging: 15-30 bags per minute (depending on the product and operator efficiency)

- Potential speed increase: 200-500%

This substantial increase in speed can have a transformative effect on a company's production capabilities. Imagine being able to fulfill orders in a fraction of the time or take on larger contracts without needing to expand your workforce significantly.

Enhancing Accuracy: Precision in Every Bag

Speed without accuracy is a recipe for disaster in the packaging world. Fortunately, semi-automatic bagging machines excel in this area too. Here's how they enhance packaging accuracy:

1. Precise Weight Control

Many semi-automatic bagging machines come equipped with integrated scales and weight control systems. These ensure that each bag contains exactly the right amount of product, whether you're packaging:

- Grains and cereals

- Pet food

- Industrial parts

- Chemicals or fertilizers

Benefit: Consistent product quantities lead to happier customers and compliance with labeling regulations.

2. Uniform Bag Filling

The automated filling mechanisms in these machines ensure that each bag is filled to the same level and density. This is particularly important for:

- Products sold by volume

- Items that need to fit precisely in secondary packaging

- Maintaining a professional appearance on store shelves

Benefit: Improved product presentation and easier downstream packaging processes.

3. Reduced Human Error

While semi-automatic machines still require human operators, they significantly reduce the potential for human error in the packaging process. This leads to:

- Fewer under or overfilled bags

- Reduced product waste

- Lower risk of contamination

Benefit: Cost savings and improved product quality control.

Versatility: Adapting to Your Product Range

One of the standout features of modern semi-automatic bagging machines is their versatility. These machines can handle a wide range of products and packaging materials, making them suitable for diverse industries.

Product Compatibility

Semi-automatic bagging machines can typically handle:

- Powders and fine granules

- Larger granules and pellets

- Small solid items (e.g., nuts, bolts, candies)

- Some liquid and semi-liquid products

This versatility means that a single machine can often serve multiple production lines or product ranges, maximizing your investment.

Packaging Material Flexibility

These machines are designed to work with various bag types and materials, including:

- Plastic bags (polyethylene, polypropylene)

- Paper bags

- Biodegradable materials

- Stand-up pouches

- Gusseted bags

The ability to switch between different bag types allows companies to adapt to changing market demands or sustainability requirements without needing to invest in new equipment.

Cost-Effectiveness: Balancing Automation and Investment

Semi-automatic bagging machines offer a cost-effective solution for many businesses, especially small to medium-sized enterprises. Here's why:

1. Lower Initial Investment

Compared to fully automatic systems, semi-automatic machines have a lower upfront cost. This makes them accessible to businesses that want to improve efficiency without breaking the bank.

2. Reduced Labor Costs

While not eliminating labor entirely, these machines significantly reduce the number of workers needed for packaging operations. A single operator can often manage one or more semi-automatic bagging machines, dramatically increasing productivity per employee.

3. Minimized Waste

The precision of semi-automatic bagging machines leads to less product waste and fewer rejected packages. This can result in significant savings, especially when working with expensive or sensitive products.

4. Scalability

As your business grows, many semi-automatic bagging machines can be upgraded or integrated into more automated systems. This scalability protects your initial investment and allows for gradual automation as your needs evolve.

Improving Workplace Safety and Ergonomics

Semi-automatic bagging machines don't just boost efficiency; they also contribute to a safer and more comfortable work environment. Here's how:

Reduced Repetitive Strain

Manual bagging often involves repetitive motions that can lead to strain injuries over time. Semi-automatic machines take over many of these repetitive tasks, reducing the risk of repetitive strain injuries among your workforce.

Improved Ergonomics

Many semi-automatic bagging machines are designed with ergonomics in mind. They often feature:

- Adjustable height controls

- Easy-to-reach interfaces

- Smooth bag handling mechanisms

These ergonomic features can help reduce fatigue and increase overall worker satisfaction and productivity.

Minimized Exposure to Products

For businesses dealing with dusty, chemical, or potentially hazardous products, semi-automatic bagging machines can provide an added layer of safety. By automating the filling process, they minimize direct contact between workers and the product being packaged.

Integration with Existing Systems

One of the key advantages of semi-automatic bagging machines is their ability to integrate seamlessly with existing production lines. This integration can take several forms:

1. Conveyor Systems

Many semi-automatic bagging machines can be easily connected to existing conveyor systems, allowing for smooth product flow from production to packaging.

2. Coding and Labeling

Some machines come with built-in or easily integrated coding and labeling systems. This allows for real-time printing of batch numbers, expiration dates, or barcodes directly onto the bags during the packaging process.

3. Data Management Systems

More advanced semi-automatic bagging machines can be connected to your company's data management or ERP systems. This integration allows for:

- Real-time production tracking

- Inventory management

- Quality control monitoring

By integrating your bagging machine with these systems, you can gain valuable insights into your packaging operations and make data-driven decisions to further improve efficiency.

Industries Benefiting from Semi-Automatic Bagging Machines

The versatility of semi-automatic bagging machines makes them valuable across a wide range of industries. Let's explore some of the sectors that can benefit most from this technology:

Food and Beverage

From grains and nuts to coffee and tea, semi-automatic bagging machines are ideal for packaging a variety of food products. They offer the precision needed for accurate portion control and the sanitary conditions required in food processing.

Pet Food and Animal Feed

The ability to handle large volumes of pellets or kibble makes these machines perfect for pet food manufacturers and animal feed producers.

Agriculture and Horticulture

Seeds, fertilizers, and soil amendments can be quickly and accurately bagged using semi-automatic machines, helping agricultural suppliers meet seasonal demands.

Chemical and Pharmaceutical

For businesses dealing with powders, granules, or small solid items, these machines offer the precision and containment needed in the chemical and pharmaceutical industries.

Hardware and Fasteners

Small parts like nails, screws, and washers can be efficiently packaged in precise quantities, making inventory management easier for hardware suppliers.

Crafts and Hobbies

From beads to model-making supplies, semi-automatic bagging machines can help craft supply companies package small items quickly and accurately.

Maintenance and Longevity: Keeping Your Machine in Top Shape

To get the most out of your semi-automatic bagging machine, proper maintenance is crucial. Here are some tips to ensure your machine continues to perform at its best:

Regular Cleaning

Establish a routine cleaning schedule, paying special attention to:

- Fill spouts and hoppers

- Sealing mechanisms

- Conveyors and chutes

Regular cleaning prevents product buildup and ensures consistent performance.

Preventive Maintenance

Don't wait for something to break. Implement a preventive maintenance schedule that includes:

- Lubricating moving parts

- Checking and replacing wear items (seals, belts, etc.)

- Calibrating weighing systems

Operator Training

Well-trained operators can spot potential issues before they become problems. Invest in comprehensive training for all staff who will be using the machine.

Software Updates

If your machine has digital controls or interfaces, keep the software up to date. Manufacturers often release updates that can improve performance or add new features.

Future Trends: What's Next for Bagging Technology?

As we look to the future, several trends are shaping the evolution of semi-automatic bagging machines:

1. IoT Integration

The Internet of Things (IoT) is making its way into packaging equipment. Future semi-automatic bagging machines may offer:

- Remote monitoring and control

- Predictive maintenance alerts

- Real-time performance analytics

2. Sustainable Packaging Solutions

With increasing focus on environmental issues, expect to see machines designed to work with:

- Biodegradable materials

- Recycled content bags

- Reduced material packaging options

3. Enhanced Customization

Advances in technology may allow for greater on-the-fly customization, such as:

- Real-time bag size adjustments

- Integrated custom printing capabilities

- Adaptive filling algorithms for different product densities

4. Improved Human-Machine Interfaces

Look for more intuitive and user-friendly interfaces, potentially including:

- Touchscreen controls

- Voice-activated commands

- Augmented reality assisted maintenance

Conclusion: Embracing Efficiency in Packaging

Semi-automatic bagging machines represent a significant leap forward in packaging technology, offering a perfect balance of speed, accuracy, and versatility. For businesses looking to improve their packaging operations without the complexity and cost of fully automated systems, these machines provide an ideal solution.

By dramatically increasing packaging speed and enhancing accuracy, semi-automatic bagging machines can transform your production capabilities. Their versatility allows them to adapt to a wide range of products and industries, while their cost-effectiveness makes them accessible to businesses of all sizes.

Moreover, the benefits extend beyond just productivity. Improved workplace safety, better ergonomics, and the potential for seamless integration with existing systems make semi-automatic bagging machines a holistic solution for modern packaging needs.

As we look to the future, the continued evolution of these machines promises even greater efficiencies and capabilities. From IoT integration to enhanced customization options, semi-automatic bagging machines are set to remain at the forefront of packaging technology.

In an increasingly competitive marketplace, investing in a semi-automatic bagging machine isn't just about keeping up – it's about staying ahead. By boosting your packaging speed and accuracy, you're not just improving your operations; you're positioning your business for long-term success and growth.

So, whether you're a small enterprise looking to scale up your production or a medium-sized company aiming to streamline your packaging process, consider the transformative potential of a versatile semi-automatic bagging machine. It might just be the key to unlocking your business's full potential in the world of efficient, accurate, and adaptable packaging.