When it comes to the production of steel sheets, precision and efficiency are key. The Cut to Length (CTL) Line 1250 MM X 0.12/0.80 MM, manufactured by FIMI spa, exemplifies top-tier engineering. Originally produced in 1982 and revamped in 2008 and 2019 by SEI Sistemi, this line offers a robust solution for processing carbon and stainless steel coils. Equipped with cutting-edge features and modern CE marking certification, this line sets the standard for reliability, precision, and safety in the steel industry.

Whether you're processing thin-gauge sheets or thicker materials, this line promises flexibility and consistent output. Let’s explore its components, benefits, and what makes it a must-have for industrial operations.

Why Is the Cut to Length Line Critical for Steel Sheet Production?

Steel sheet production demands precision and uniformity. In industries such as construction, automotive, and appliance manufacturing, minor imperfections in steel sheets can result in costly inefficiencies or product failures. This is where a Cut to Length Line becomes indispensable.

A CTL line transforms large steel coils into custom-sized sheets with unparalleled precision. The 1250 MM X 0.12/0.80 MM Cut to Length Line excels in:

- Versatility: Handles a range of thicknesses (0.12 to 0.80 mm) and processes both raw and annealed steel.

- Customization: Allows for min-max sheet sizes from 350 x 500 mm to 1250 x 2000 mm.

- Productivity: Streamlines operations by reducing manual handling, improving efficiency, and ensuring consistent output.

By leveraging advanced technology like electronic touch-type thickness gauges and rotating shears, this CTL line delivers results that meet or exceed industry standards.

Key Features of the Cut to Length Line 1250 MM

1. Comprehensive Material Processing Capability

This CTL line accommodates both carbon and stainless steel. Whether dealing with raw or annealed material, the line's robust design ensures durability and adaptability. Its uncoiler capacity of up to 16 tons enables seamless handling of large steel coils, reducing downtime between operations.

2. Advanced Leveler Design for Thickness Adjustments

The line features two interchangeable leveling benches:

- 0.12 to 0.40 mm bench: Ideal for thin-gauge steel sheets requiring high precision.

- 0.40 to 0.80 mm bench: Designed for thicker sheets, ensuring stability during processing.

This dual-bench system offers operators flexibility, catering to diverse project requirements.

3. Cutting-Edge Automation Components

Automation enhances precision, reduces human error, and improves safety. This CTL line integrates:

- Electronic touch-type thickness gauges for real-time measurement.

- Rotating shears for smooth and precise cutting.

- Motorized pinch-rolls and tape-centering devices for alignment and control.

These features not only boost productivity but also ensure minimal material wastage.

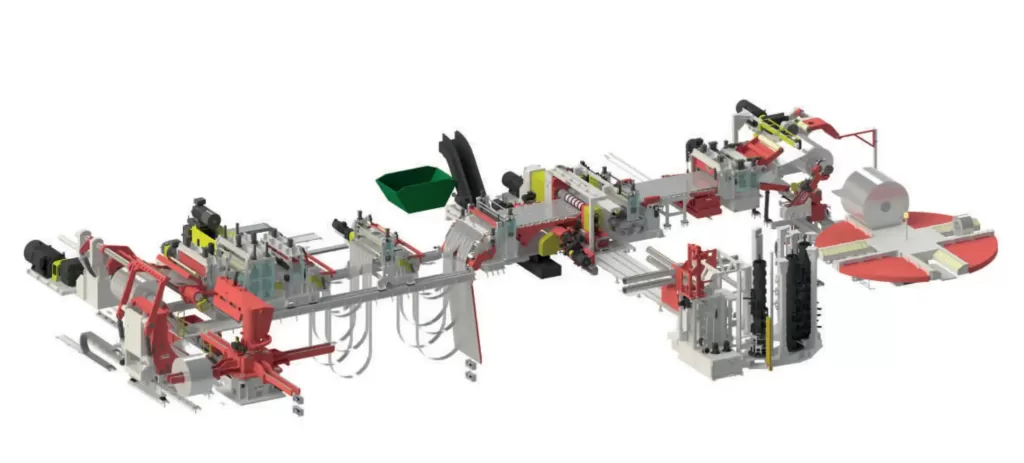

Exploring the List of Machines in the CTL Line

The functionality of the CTL line is supported by an array of advanced machines, each playing a crucial role in the production process. Here’s a breakdown of the key components:

1. Uncoiler and Loading Systems

- Storage ramps for 2 coils: Maximizes operational readiness by staging coils for uninterrupted production.

- Coil loading cradle: Simplifies the transfer of coils onto the uncoiler.

- Unwinding reel: Accommodates various coil sizes with Ø 400 and Ø 508 overhangs.

2. Leveling and Aligning Systems

- Pinch-roll for leveling entry: Ensures smooth strip feeding into the leveler.

- Descent and ascent saddles: Stabilize the material during processing, particularly in the loop pit.

3. Precision Cutting and Sorting

- Rotating shear: Delivers clean, accurate cuts at high speeds.

- Swiveling belts: Redirect defective strips or waste into collection boxes, streamlining waste management.

- Collection boxes: Organize trimmed and processed sheets for stacking and packaging.

4. Safety and Control

- Hydraulic service units: Power all major components while maintaining reliability.

- Electric and PLC control systems: Provide centralized oversight, allowing operators to monitor and manage the entire process seamlessly.

Why Choose the FIMI CTL Line Over Competitors?

With so many options available, selecting the right CTL line can be daunting. Here’s what sets the FIMI CTL Line apart:

- Proven Longevity and Performance: Originally built in 1982 and modernized through revamping in 2008 and 2019, this line combines robust engineering with modern technology.

- CE Certification: Updated safety and compliance standards ensure operator protection and adherence to industry regulations.

- Customizable Output: From smaller sheets (350 x 500 mm) to larger formats (1250 x 2000 mm), this line meets varying production needs.

- Integrated Safety Features: Electric bar barriers, photocells, and enhanced control systems ensure operational safety and reliability.

Revamping Benefits: Why Upgrades Matter

The FIMI CTL Line underwent significant revamping in 2008 and 2019, carried out by SEI Sistemi, a leader in industrial machinery upgrades. But why does revamping matter?

1. Enhanced Efficiency Through Modernization

Revamping introduced updated controls, software, and hardware, transforming the original 1982 design into a state-of-the-art system. This included:

- New PLC systems: For precise and automated control of operations.

- Modern drives and electrical cables: Ensuring energy efficiency and improved reliability.

- Upgraded software: Allowing better monitoring and fine-tuning of production parameters.

2. Compliance with Current Standards

With the addition of CE marking in 2019, the line adheres to strict European safety and quality regulations. This certification ensures:

- Improved operator safety.

- Enhanced environmental compliance.

- Reliable performance under modern standards.

3. Extended Equipment Lifespan

Revamping has extended the operational life of the line by integrating new components while retaining the durability of its original structure. This reduces the total cost of ownership and ensures the system remains competitive in today's industrial landscape.

Real-World Applications of the FIMI CTL Line

The versatility of the FIMI CTL Line makes it suitable for a wide array of industries. Below are some examples of its practical applications:

1. Automotive Industry

Precision is crucial in the automotive sector, where steel sheets are used for body panels and structural components. The CTL line ensures consistent thickness and clean cuts, making it ideal for these applications.

2. Construction

From roofing materials to structural supports, the construction industry relies on steel sheets of varying sizes and thicknesses. The ability to handle raw and annealed carbon and stainless steel makes this line a valuable asset for construction material production.

3. Appliance Manufacturing

Appliances like refrigerators, ovens, and washing machines require steel sheets that are both durable and aesthetically pleasing. The FIMI CTL Line ensures sheets are cut to exact dimensions, reducing waste and ensuring compatibility with manufacturing processes.

Maintenance and Support: Keeping Your Line Operational

Investing in a high-performance line like the FIMI CTL requires proper maintenance to maximize uptime and productivity. Here are the key maintenance considerations:

1. Scheduled Preventive Maintenance

Regular inspections and servicing of critical components—such as hydraulic systems, rotating shears, and pinch-rolls—prevent unexpected breakdowns.

2. Replacement of Wear Components

Despite its robust design, components like rollers and shears are subject to wear. Ensuring timely replacement with certified parts minimizes disruptions.

3. Technical Support and Training

With the CE-certified system, operators can access training modules and technical manuals for optimal use. Remote support and on-site services provided by SEI Sistemi further enhance operational reliability.

Exploring Other Lines for Steel Sheet Processing

In addition to the Cut to Length Line 1250 MM, several other lines are available to meet varying production requirements:

1. Used CTL Line 2000 X 6 MM

Designed for processing thicker steel sheets, this line caters to industries requiring heavy-duty applications.

2. Used Slitter Line for Stainless Steel 1550 X 4 MM

This slitter line offers precise slitting for stainless steel sheets up to 4 mm thick, ideal for high-demand environments.

3. Used Satin Sheet Line 2000 X Up to 10 MM

Specialized for satin finishes, this line processes sheets up to 12 meters in length, making it perfect for decorative and high-precision applications.

Conclusion

The FIMI CTL Line 1250 MM X 0.12/0.80 MM represents the pinnacle of engineering in steel sheet production. With its ability to handle a wide range of materials, precise customization options, and seamless integration of modern technology, it is a valuable asset for industries worldwide. Its revamping history underscores its durability and relevance, while the CE marking ensures safety and compliance.

Whether you need a solution for automotive manufacturing, construction, or appliance production, this line offers unmatched flexibility and reliability. Coupled with robust support and maintenance options, it stands as a future-proof investment for businesses looking to optimize their operations.