More information: http://www.fhopepack.com/steel-tube-packing-machine.html

Flow wrappers are types of packaging machines that are designed to wrap products in a continuous film or bag, providing a protective barrier around the product. In the case of automatic pipe and tube bagging, the flow wrapper is customized to handle long, cylindrical products, such as stainless steel tubes.

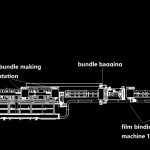

The automatic pipe and tube bagging by flow wrapper typically includes a conveyor system to feed the tubes into the machine, where they are then wrapped in a continuous film or bag. The machine may also include sensors and other technology to ensure accurate placement and sealing of the packaging material.

The high speed of up to 50m per minute is made possible by the continuous flow of the tubing through the machine, with the packaging material being sealed and cut at regular intervals. It is impressive and may make it a suitable option for high-volume production environments. The use of bag packaging can also provide additional protection for the tubes during stacking and delivery, reducing the risk of scratching or other damage.

The use of bag packaging can provide additional benefits beyond protection during transportation and handling. For example, bag packaging can provide a more professional appearance for the product, making it more appealing to customers. Bag packaging can also help to keep the product clean and free from dust or other contaminants.

Overall, automatic pipe and tube bagging by flow wrapper is a valuable and useful solution for industries that handle long, cylindrical products such as stainless steel tubes, which are looking for a safer and more efficient way to package and transport them.The use of flow wrappers can significantly reduce the need for manual labor, increase production efficiency, and provide additional protection and benefits for the product.