Safe and Compliant Steel Coil Packing Methods for Export

Introduction: The Critical Role of Export Packaging for Steel Coils

Exporting steel coils globally presents unique logistical challenges. Ensuring these heavy, valuable products arrive at their international destination undamaged and fully compliant with all regulations is essential for business success. Steel coil packing for export is far more than just covering the product; it's a strategic process involving protection against physical damage, environmental factors like corrosion, and adherence to complex international shipping standards.

This guide provides a comprehensive overview of the best practices for safe and compliant steel coil packing. We will explore essential packaging materials, critical handling procedures, navigating international regulations, implementing quality control, considering environmental sustainability, and leveraging technology. Following these guidelines will help ensure your steel coils reach their destination in optimal condition, meeting both regulatory requirements and customer expectations.

1. Why Proper Steel Coil Packaging Matters for Export

Effective packaging is a cornerstone of successful steel coil exportation. Its primary functions are multifaceted:

- Protection: Shielding the coil from physical impacts, scratches, dents, and other damage during handling, loading, transit, and unloading.

- Corrosion Prevention: Protecting against moisture, humidity, salt spray, and atmospheric contaminants that can cause rust and degrade the steel quality, especially during long sea voyages.

- Handling Efficiency: Facilitating safe and efficient movement using standard equipment like forklifts and cranes.

- Compliance: Meeting the specific packaging and labeling requirements of the destination country and international shipping authorities.

- Safety: Ensuring the heavy coils are secured properly to prevent shifting or accidents during transport, protecting personnel and other cargo.

Neglecting proper packaging can lead to costly product damage, insurance claims, customs delays, regulatory fines, and damage to your business reputation. Conversely, robust and compliant packaging ensures product integrity, customer satisfaction, and smoother international trade operations.

2. Essential Packaging Materials for Exporting Steel Coils

Choosing the correct steel coil packaging materials is fundamental to protecting your product during its export journey. Combining several layers and types of materials provides comprehensive protection. Key materials include:

2.1. Inner Protection (Corrosion and Surface)

- VCI Paper/Film: Volatile Corrosion Inhibitor (VCI) materials release harmless compounds that form a protective layer on the steel surface, actively preventing rust and corrosion. This is crucial for long transit times or humid destinations.

- Stretch Film/Shrink Wrap: Provides a tight, conforming barrier against dust, dirt, and moisture. Multiple layers can enhance puncture resistance.

- Waterproof Kraft Paper: Often laminated or coated, this paper provides an additional moisture barrier.

2.2. Edge and Surface Protection

- Edge Protectors: Made from cardboard, plastic, or metal, these protect the vulnerable inner and outer edges (eyes and circumferences) of the coil from damage caused by strapping or impacts.

- Inner Diameter (ID) and Outer Diameter (OD) Protectors: Specially shaped protectors (often metal or hard plastic rings/sheets) shield the ID and OD surfaces from direct contact with strapping, pallets, or handling equipment.

2.3. Structural Support and Handling

- Steel Banding: High-tensile steel straps are essential for securely unitizing the coil and fastening it to pallets or skids. Proper tensioning and placement (circumferential and radial/eye bands) are critical.

- Polyester (PET) Strapping: A strong alternative to steel, PET strapping is lighter, safer to handle, doesn't rust, and offers good shock absorption. Its suitability depends on coil weight and transport conditions.

- Pallets and Skids: Robust wooden (fumigated/heat-treated according to ISPM 15 standards) or metal pallets/skids elevate the coil, allow forklift access, and distribute weight. Custom cradles or saddles integrated into the skid can provide better support for the coil's shape.

2.4. Outer Protection

- Outer Wraps: Heavy-duty materials like waterproof tarpaulin, reinforced plastic sheeting, or specialized coil wrap fabrics provide the final barrier against weather, dirt, and physical damage during outdoor storage or transit.

- Steel Sheet Encasement: For maximum protection, especially for high-value coils, a full or partial encasement using light-gauge steel sheets can be employed.

The specific combination of materials depends on the coil type, dimensions, weight, destination climate, mode of transport, and customer requirements.

3. Adhering to International Shipping Standards and Regulations

Compliance is non-negotiable when exporting steel coils. Failure to meet standards can result in shipment rejection, delays, fines, or damage. Key areas include:

3.1. ISPM 15 (Wood Packaging Materials)

- The International Standard for Phytosanitary Measures No. 15 (ISPM 15) requires that all solid wood packaging material (WPM) used in international trade (like pallets, crates, dunnage) be debarked and then heat-treated or fumigated with methyl bromide to kill insects or fungi.

- Compliant WPM must be stamped with the official IPPC mark. Using non-compliant wood can lead to your entire shipment being quarantined or refused entry. Verify compliance with your packaging supplier. Learn more about ISPM 15.

3.2. ISO Standards

- While there isn't one single ISO standard covering all aspects of steel coil packing, relevant standards address packaging materials, testing methods, container loading, and securing cargo. Adhering to best practices derived from ISO guidelines enhances safety and global acceptance.

3.3. Customs and Destination Country Regulations

- Each country has specific import regulations regarding packaging, labeling, and documentation. Research the requirements for your destination country thoroughly. This includes:

- Labeling: Country of origin, handling symbols (e.g., "Use No Hooks," "Keep Dry"), weight, dimensions, consignee information.

- Documentation: Accurate packing lists, commercial invoices, and bills of lading are essential.

3.4. Carrier Requirements

- Shipping lines (ocean carriers), trucking companies, and railways often have their own specific rules for accepting and loading heavy cargo like steel coils. Consult your freight forwarder or carrier regarding securement methods (e.g., blocking and bracing within containers) and weight distribution.

steel coil packing machine for sale 4. Best Practices for Safe Handling of Steel Coils

Safe handling procedures are as vital as the packaging itself. Heavy steel coils pose significant safety risks if mishandled. Implement these best practices:

4.1. Use Appropriate Lifting Equipment

- Coil Lifters (C-Hooks, Tongs): Use specialized C-hooks or coil lifting tongs designed for the specific weight and size of the coils. Ensure they are rated for the load and regularly inspected.

- Forklifts with Coil Rams: For horizontal eye coils, forklifts equipped with specialized coil rams (poles) are often used. Ensure the ram capacity matches the coil weight.

- Overhead Cranes: Utilize cranes with appropriate lifting attachments (hooks, tongs, magnets – use magnets with extreme caution and appropriate safety protocols).

- Regular Maintenance: All lifting equipment must be regularly inspected, maintained, and certified according to safety regulations.

4.2. Implement Safe Handling Procedures

- Clear Communication: Use standard hand signals or radio communication between crane/forklift operators and ground personnel.

- Secure Zones: Establish clear exclusion zones around lifting operations. Keep personnel away from suspended loads.

- Stable Loading: Ensure coils are placed on stable, level surfaces and properly secured on transport vehicles or within containers using appropriate dunnage, blocking, and bracing.

- Coil Orientation: Handle and store coils according to specifications (e.g., eye-to-sky vs. eye-horizontal) to prevent damage or instability.

4.3. Comprehensive Employee Training

- Task-Specific Training: Train all personnel involved in handling, packaging, and loading steel coils on safe operating procedures, hazard recognition, and the correct use of equipment.

- Refresher Courses: Conduct regular safety meetings and refresher training sessions.

- Awareness: Emphasize the weight and potential energy of steel coils and the importance of vigilance.

5. Implementing Quality Control in Steel Coil Packaging

A robust quality control (QC) process ensures consistency and effectiveness in your packaging operations.

5.1. Material Inspection

- Inspect incoming packaging materials (straps, wraps, pallets, protectors) for defects or damage before use.

5.2. Process Monitoring

- Monitor the packaging process itself. Ensure correct materials are applied in the right sequence, straps are properly tensioned, and wraps are sealed effectively.

- Verify correct labeling and marking placement.

5.3. Final Package Inspection

- Conduct a final inspection of the fully packaged coil before dispatch. Check for:

- Secure and correctly tensioned strapping.

- Intact and undamaged wrapping.

- Properly placed and undamaged edge/ID/OD protectors.

- Correct labeling and ISPM 15 marks (if applicable).

- Stable positioning on the pallet/skid.

5.4. Documentation and Feedback

- Maintain detailed records of packaging specifications used for each shipment.

- Photograph packaged coils as evidence of condition before shipping.

- Establish a system for documenting any issues found during QC checks and implement corrective actions. Encourage feedback from warehouse staff and customers.

6. Environmental Considerations and Sustainable Packaging

Sustainability in packaging is increasingly important due to regulations and customer preferences. Consider these approaches:

6.1. Choose Sustainable Materials

- Recycled Content: Use packaging materials made from recycled content where feasible (e.g., recycled plastic films, cardboard protectors).

- Recyclable Materials: Select materials that are easily recyclable in the destination country.

- Biodegradable Options: Explore biodegradable VCI films or paper wraps where appropriate, balancing protection needs with environmental impact.

6.2. Optimize Material Usage

- Reduce: Avoid over-packaging. Use engineering analysis to determine the minimum amount of material needed for adequate protection.

- Reuse: Implement systems for reusing pallets, skids, or certain types of protective materials where practical and hygienic.

6.3. Source Responsibly

- Partner with packaging suppliers who demonstrate strong environmental commitment and offer sustainable material options.

- Ensure wood suppliers comply with sustainable forestry practices in addition to ISPM 15.

Adopting sustainable practices can enhance your brand image, meet regulatory demands, and potentially reduce costs through optimized material use.

7. Leveraging Technology for Enhanced Packaging and Tracking

Modern technology offers tools to improve the efficiency, safety, and traceability of steel coil packaging and export.

7.1. Automated Packaging Lines

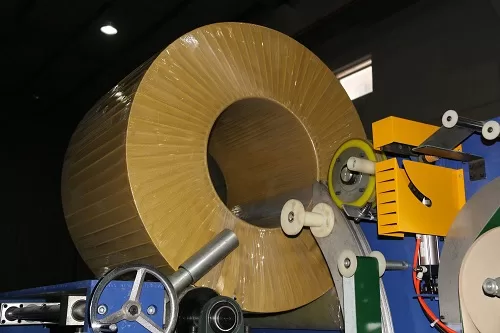

- Systems for automated stretch wrapping, strapping, or labeling can improve consistency, speed up the process, and reduce manual handling risks. Consider solutions like automatic steel coil wrapping machines for higher volume operations.

7.2. Advanced Tracking and Monitoring

- GPS Trackers: Monitor the real-time location of high-value shipments.

- Environmental Sensors: Use data loggers or sensors within the packaging to monitor temperature, humidity, and shock/impact events during transit. This data can help identify issues and improve future packaging strategies.

- RFID/Barcoding: Improve inventory management and tracking throughout the supply chain.

7.3. Data Analytics

- Analyze data collected from QC checks, transit monitoring, and customer feedback to identify trends, pinpoint weaknesses in the packaging process, and make data-driven improvements for cost reduction and damage prevention.

steel wire packing machine with paper4 Conclusion: Secure Your Exports with Optimized Steel Coil Packaging

Safe and compliant packaging for exported steel coils is a critical investment, not an expense. It requires a holistic approach encompassing the right materials, adherence to international standards like ISPM 15, meticulous handling procedures, robust quality control, sustainable practices, and the smart use of technology.

By prioritizing these elements, steel exporters can significantly reduce the risk of damage, ensure compliance with global regulations, enhance safety throughout the supply chain, and build a reputation for reliability and quality. Implementing a thorough and well-documented steel coil packing strategy is essential for navigating the complexities of international trade and ensuring your valuable products arrive safely at their destination, every time.

Get Your Best Solution !